In a recent video, my esteemed colleague Miles Budimir and I reviewed the features of an Accu-CoderPro encoder from Encoder Products Company. Contained within the rugged industrial housing are advanced electronics that let designers program the encoder to exact application needs. Using EPC’s optional programming module, users can select output type, 32 different waveforms, and any resolution from 1 to 65,536 CPR.

As explained here in more detail, the Model 25SP Programmable Accu-CoderPro shaft encoder is specifically designed for industrial environments …

During our demo, we connected an interface cable through a USB Module to program the encoder with the software. Electronics let us program the encoder to exact application needs. Using EPC’s optional programming module, users can select output type, 32 different waveforms, and any resolution from 1 to 65,536 CPR — that’s 262,144 counts using 4x quadrature counting. Here is an outtake of our use of the software:

The programming lets designers configure a single encoder to multiple applications, enabling one encoder to replace many different part numbers. Tunable settings include current resolution or CPR, output type, quadrature direction, and waveform values. This way of using one encoder for lots of different axis setups trims inventory costs and downtime should one encoder need replacement. The 25SP also configures and ships with specs pre-programmed, with no onsite programming needed.

Available options are line driver, push pull, open collector, pull up, 5-V line driver, or 5-V push pull. Units ordered in the three most common output types can be programmed as such. Units ordered as H5 or P5 regulate the output to 5 Vdc and can only be programmed as such.

This software also has a Tools menu to reread the encoder settings, to teach an index location or set index position to the current shaft position. Sometimes called a “marker pulse” the index is a separate output that happens at a given position at each full encoder rotation. Another option under the Tools menu is a View Diagnostic Log command to open a list of events or errors.

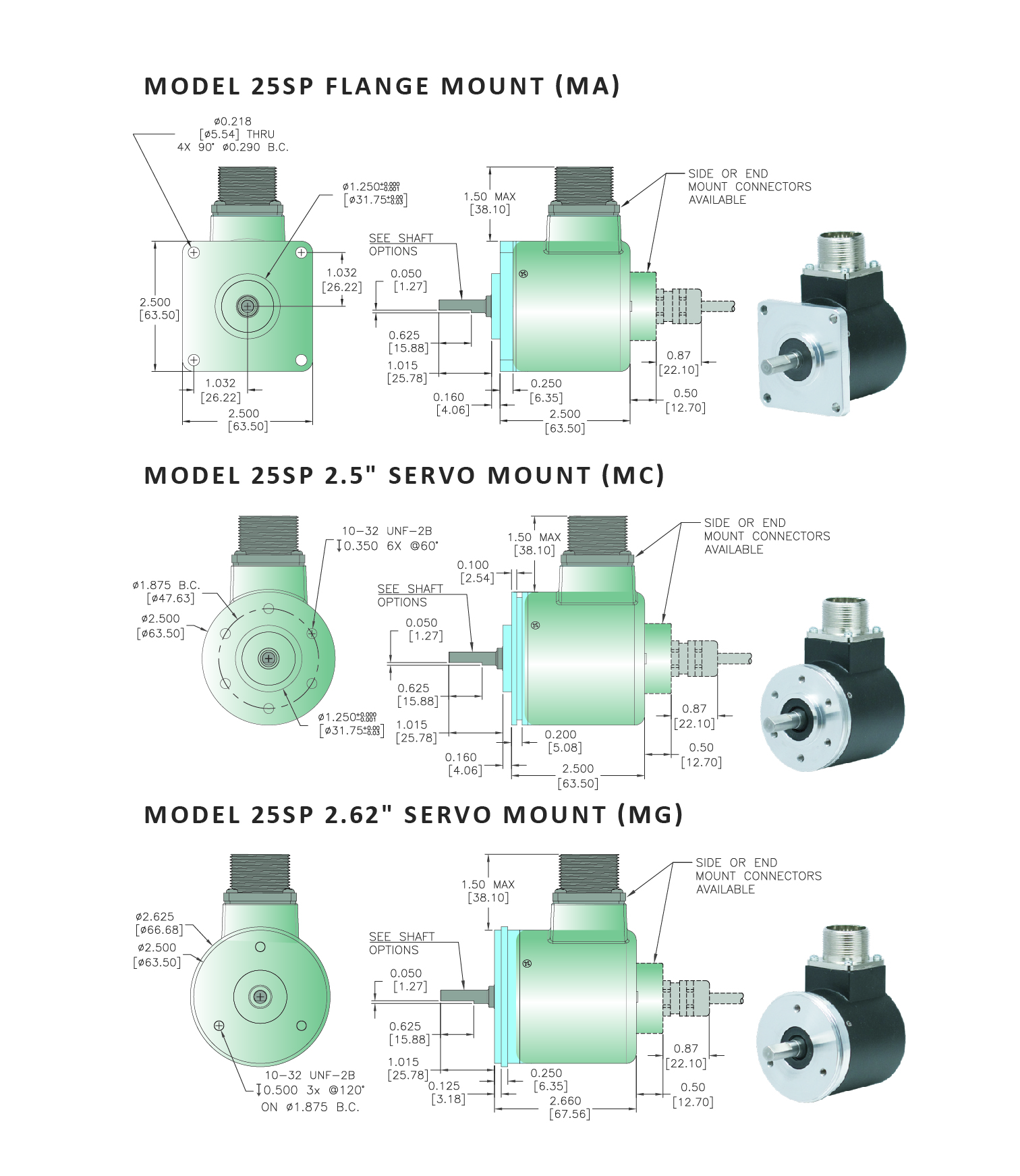

The Model 25SP Accu-CoderPro comes standard with dual bearings rated 80-lb axial or radial … and may be specified with up to IP67 sealing. The encoder also comes in three different mounting versions — an MA flange-mount version; an MC 2.5-inch servo-mount version; and an MG 2.62-inch servo-mount version. Input voltage is 4.75 to 30 Vdc and input current is 100 mA. Accuracy is better than 0.013° or 47 arc-sec from true position; top shaft speed is 8,000 rpm but EPC makes faster versions upon request. Click the image below to see the details of the three mounting versions.

Leave a Reply

You must be logged in to post a comment.