Power and free conveyors are designed for manufacturing environments where products need to be transported in a non-linear fashion — that is, where materials aren’t necessarily delivered in the order they were loaded or at the same pace. Traditional “linear” conveyors, on the other hand, lack the flexibility to handle manufacturing environments where different production processes run at different cadences or where various materials have different flow paths.

Because of their flexibility in handling and delivering products, power and free conveyors are also referred to as “asynchronous” or non-linear conveyors.

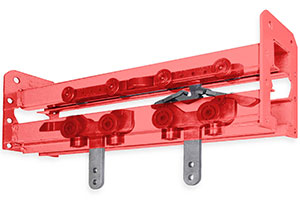

The defining feature of a power and free conveyor is that it consists of two tracks — an upper track and a lower track. The upper track is powered by a chain, and the lower track is unpowered. Trolleys, which carry the load, run on the lower track, supported by rolling wheels. Mechanical devices — often referred to as pusher dogs — on the powered track engage with the trolleys to move them and disengage with the trolleys to stop them.

The pusher dogs are engaged and disengaged by cam action caused by a trolley in front or by a stop blade positioned along the powered chain. Air-activated stops, triggered by switches, can also be used to control the movement of trolleys.

Much like cars on a road, conveyor “traffic” can also be merged or diverted among multiple conveyor lines, and both sharp turns and elevation changes can be executed. And unlike traditional linear conveyors, power and free versions can allow products to accumulate, or “stack up” by holding trolleys stationary while other trolleys “catch up” and join them. The trolleys can then be released in the required sequence. All of this is accomplished through mechanical linkages via the pusher dogs and trolleys, without requiring complex automation.

To maximize space, especially during accumulation, trolleys can be connected via rigid load bars that set the spacing between trolleys at as little as 6 inches (depending on the size and shape of the load). And storage density can be maximized with trolleys that hold the load diagonally relative to the conveyor path.

Circuits of conveyors up to 300 feet can be controlled with just one motor, and complex “traffic” patterns and timing sequences can be controlled via sensors triggered by a PLC or PC-based controller. In addition, bar codes or RFID tags on the trolleys can be used to identify individual loads and carry instructions for sequencing.

This video from Caldan Conveyor A/S demonstrates how power and free conveyors work, including their ability to accumulate, stage, merge, and divert products.

While most power and free conveyors are mounted overhead, above the working area, and carry products below the tracks, floor-mounted designs are available that carry the product above the tracks. This is especially useful when overhead space is a concern, or when potential contamination from the conveyor or product is an issue, as is often the case in cleanroom environments. And when overhead space is limited but floor-mounting is not an option, some manufacturers offer overhead versions with powered and non-powered tracks positioned side-by-side, rather than in a top-and-bottom configuration.

Power and free conveyors are custom-designed for each application and can carry loads from just a few pounds to several hundred pounds. They’re used extensively in the automotive industry, where robot cells are sometimes used to load/unload products from the trolleys or to perform work on the parts being conveyed as they’re held stationary. And power and free designs are available in heat and corrosion-resistant versions, so they can transport loads through processes such as washing and painting or through ovens.

Leave a Reply

You must be logged in to post a comment.