Attendees at the Automation Technology Expo West (ATX West) in Anaheim, Calif. Feb. 6 to 8 can learn how to enhance productivity using intelligent motion systems from Rockwell Automation. The systems that will be demonstrated use independent cart technology to help manufacturers reach new levels of throughput and process optimization.

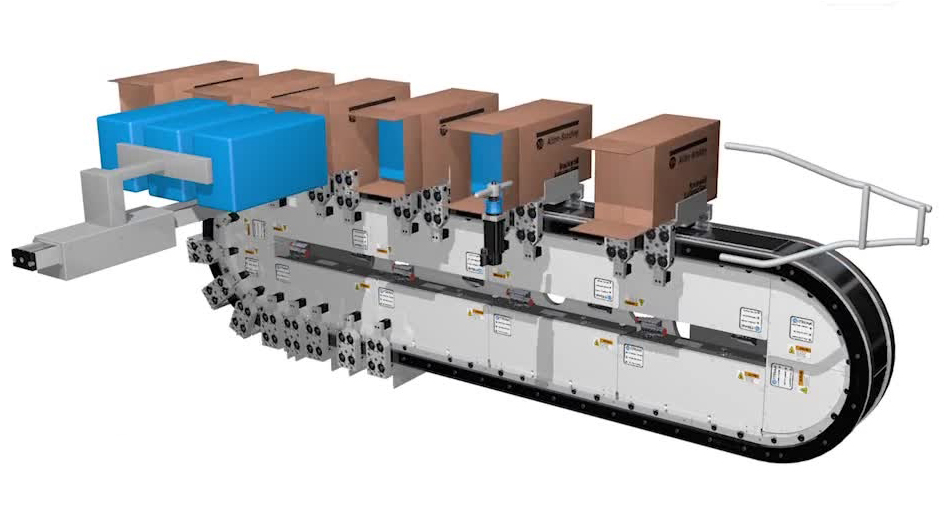

Rockwell Automation will be exhibiting the MagneMover LITE intelligent conveyor system and iTRAK intelligent track system in a machine demonstration at the MagneMotion Booth #4401. The intelligent motion systems abandon the rotary-driven chains, belts and gears of traditional systems. Instead, they use independent cart technology and simple software profiles that can be modified with the push of a button. This technology can deliver greater speed and flexibility in motion applications.

Attendees will also see independent cart technology applied to customer applications at the Mikron Corp. Booth #4115, TSS Technologies Booth #4455 and DESTACO Booth #4276.

Independent cart technology can boost productivity over traditional mechanical systems.

“Intelligent motion systems such as iTRAK are changing how machine builders approach motion control,” said Oliver Haya, product manager, iTRAK, Rockwell Automation. “Machines builders can use the system’s independently controlled moving carts to customize operations to specific customer needs. And they can take advantage of the system’s fewer moving parts to help reduce downtime and maintenance.”

The MagneMover LITE intelligent conveyor system outperforms conventional belt and chain conveyors for demanding motion requirements. It is designed to quickly and efficiently move light loads, and offers thousands of possible design configurations.

The iTRAK intelligent track system uses independent control of multiple, magnetically propelled movers on straight and curved paths to increase speed, throughput and flexibility.

These intelligent motion systems can be used in assembly, process, test and manufacturing applications. They are suitable for the medical device, assembly, automotive, pharmaceutical, packaging and optical industries.

Rockwell Automation Inc., the world’s largest company dedicated to industrial automation and information, makes its customers more productive and the world more sustainable. Headquartered in Milwaukee, Wis., Rockwell Automation employs approximately 22,000 people serving customers in more than 80 countries.

Leave a Reply

You must be logged in to post a comment.