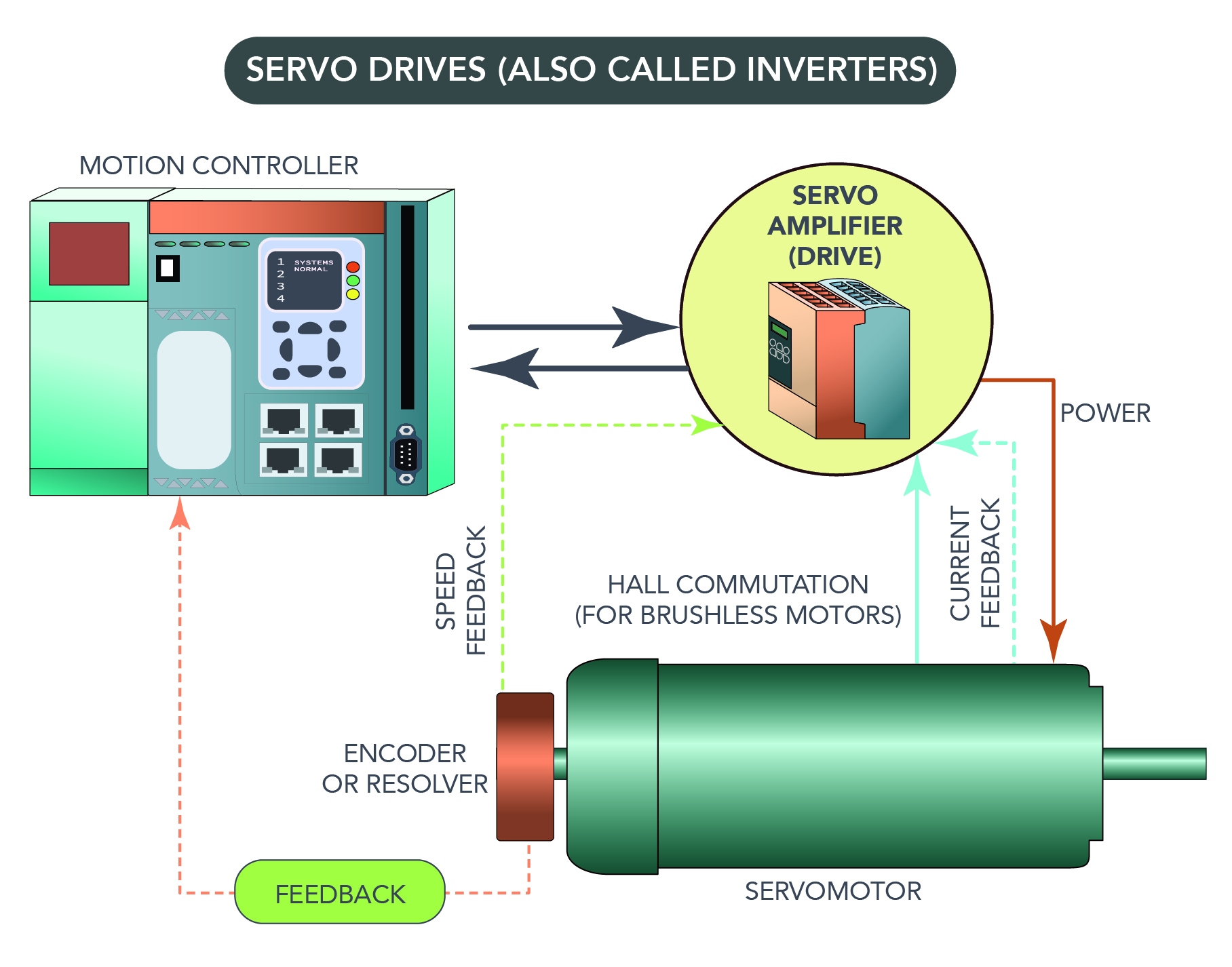

Let’s start with the term servo drive. Here’s what a drive does in a servo system: It basically takes an input signal from a controller and amplifies that signal which is then sent to the motor. And in that description is the key. A drive serves to amplify a signal. Amplification is needed because control signals are too low (in terms of current) to power the windings of a motor, which require higher current levels.

So functionally speaking, signal amplification is what is going on inside of a servo drive. Hence, the reason a drive is sometimes referred to as a servo amplifier.

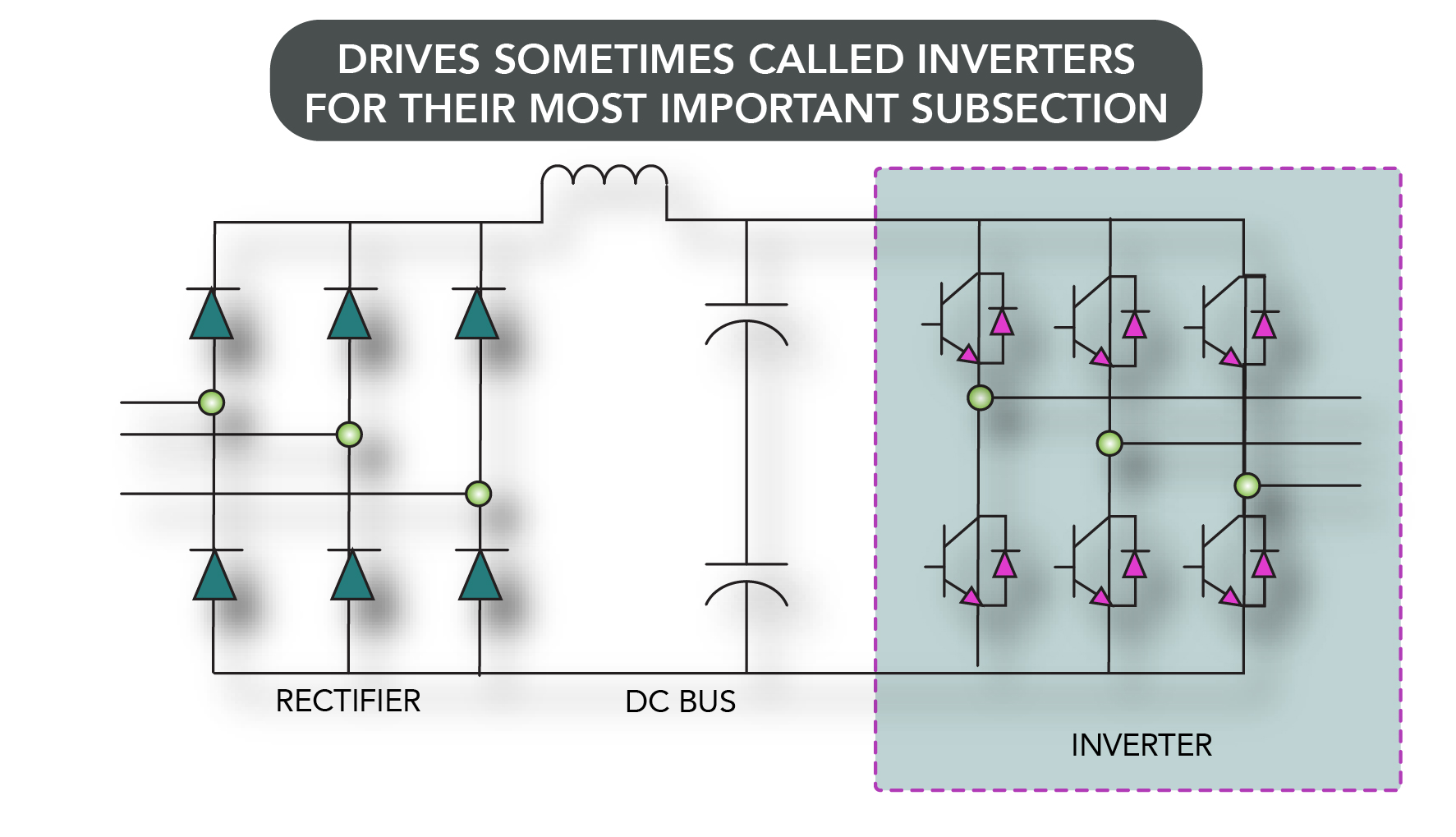

Now consider the term inverter. To understand this name for drives, we need to look at the electronic functions inside of a drive.

An electronic inverter converts dc power to ac. Drives contain inverters to generate the ac signals needed to drive a motor. So labeling something a servo inverter really only refers to one of the electronic systems in a drive … even though engineers may use it interchangeably with the word “drive” to refer to the same thing.

That brings us to the term servo controller. This name is perhaps the most problematic. That’s because traditionally a controller is where the control signals for the motor originate.

Strictly speaking, a servo controller does not supply the currents for the motor. That’s what a drive does.

The controller generates the control signals, which are then amplified by the drive and sent to the motor.

Even so, contemporary designs continue to integrate these older stand-alone components and functions into one unit.

So a drive of today — in addition to performing standard drive functions — may also be generating the control signals. Or a controller may have drive functionality within it, for example.

Either way, knowing what a drive functionally does (as well as having access to product specs) can help determine what is being referred to when any of these terms is used. ⚙️ Article updated August 2019.

Leave a Reply

You must be logged in to post a comment.