In a recent video recorded at the Design World studios, I teamed up with my colleague Paul Heney to review the features of three motors (including slotless brushless motor options) from Koford Engineering in Winchester, Ohio. Related article: What are the differences between slotted and slotless motors?

Brushless motors are like brush motors but use electronic commutation — usually on a separate circuit board. Other names for specific brushless-motor types are dc brushless motors, ac brushless motors, and permanent-magnet synchronous motors.

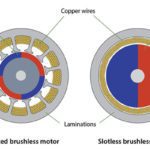

Koford motors range in size from 16 mm to 129 mm in diameter. In all but the largest size (a 129-mm Series) the motors are slotless for cog-free rotation — which is especially important in servo applications. Slotless motors also have higher power density and efficiency than slotted. That said, slotted motors excel in designs needing short axial lengths.

In this video, my colleague Paul Heney also outlines the features of the 16-mm Series brushless motor — a motor suitable for military, medical, dental, and industrial applications. It delivers speeds to 53,040 rpm with cog-free operation. Its ML insulation is rated to 220° C and its bearings are lubricated with premium synthetic grease that works in temperatures from -73° to 149° C. (It’s also available in sensorless versions or with Hall sensors.)

Unlike most slotted motors, Koford motors also exhibit highly linear behavior … and a slotted motor with the same phase resistance and rpm as a Koford motor may deliver only half of the peak torque. Stall torque is Kt times current, but at stall, the winding will warm and increase resistance …

… so full stall torque may only be available for a fraction of a second. Usually the drive’s current limit is far lower than motor stall current, so this is not a problem.

Motor speeds are available from 0 to 200,000 rpm with power levels from 1 W to 2 kW. As mentioned, these Koford motors come in either sensorless configurations — which have three leads, as in this 23-mm Series motor we show in the video — or with Hall sensors having eight leads — as in the 16-mm motor we review. Sensorless motors are suitable for pumps, blowers, and beam choppers. Hall-sensor motors are good for motion control and servo applications.

Options such as ceramic hybrid bearings, vacuum compatibility, steam autoclave compatibility, winding-temperature sensors, gearboxes, encoders, hollow shafts and lead screw shafts are offered. Typical applications are surgical tools, aerospace servos, spacecraft, scientific instruments, pumps and fans. For more information, visit Koford Engineering at koford.com.

Leave a Reply

You must be logged in to post a comment.