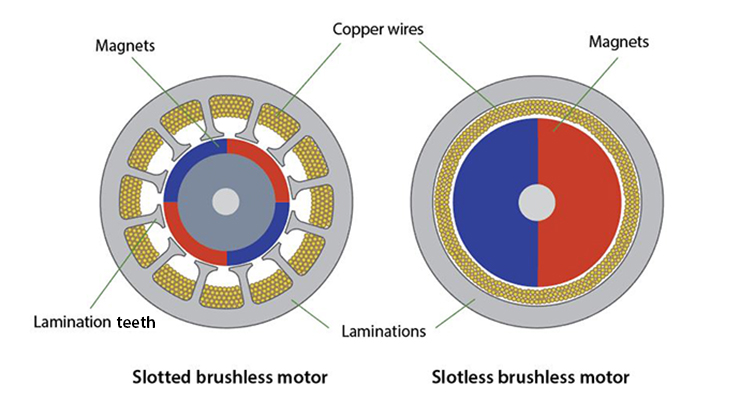

The original brushless DC (BLDC) motors were designed with slotted stators, and the majority of BLDC motors are still made this way. But this design produces cogging torque, which makes it difficult to achieve smooth motion, especially at slow speeds. To eliminate this effect, a new design was developed, eliminating the slots in the stator (which are the root cause of cogging torque), and slotless motors were born.

In a slotted motor design, the stator is made of slotted steel laminations that are stacked together, and copper windings are inserted into these slots. (The design of the stator is sometimes referred to as having “teeth.”) The slotted motor design is simple and inexpensive to manufacture, but it has a major drawback—cogging torque. Cogging torque (also referred to as “detent torque”) is a result of the permanent magnets in the rotor attempting to line up with the slots, or teeth, of the stator. The primary effect of cogging torque is that it causes motor rotation to be jerky (not smooth), especially at low motor speeds.

The term “iron core” is commonly used when discussing slotted linear motors. This originates from the fact that the assembly of stator windings encased in a steel, slotted stator is sometimes referred to as an “iron core.” Slotless linear motors, on the other hand, are often referred to as “air core” motors.

In a slotless motor, there are no iron teeth to support the windings. Instead, the stator lamination is constructed of steel rings that are stacked together, and the windings are encapsulated in an epoxy resin, which gives the winding structure shape and rigidity. This “self-supporting” winding is placed in the air gap between the stator lamination and the rotor.

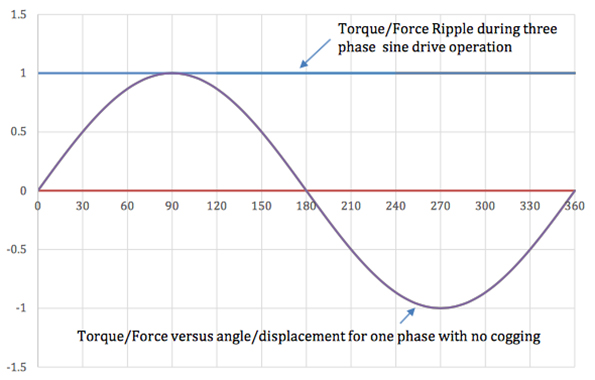

The primary benefit of a slotless motor design is that the lack of teeth in the lamination eliminates cogging torque and results in a motor with very smooth running characteristics. Torque production is predictable and highly controllable, because in the absence of these uncontrolled disturbances (i.e. cogging torque), motor torque production is directly related to the current supplied to the winding.

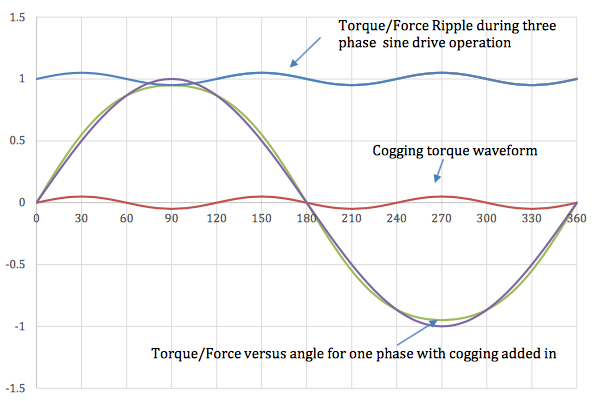

Purple = theoretical sinusoidal torque versus angle

Green = compromised result of cogging torque

Red = cogging torque

Blue = resulting torque from all three phases operating together

Images credit: Celera Motion

There are other benefits to the slotless design. First, the elimination of cogging also significantly reduces audible noise. And since there’s no iron core, inductance is very low and current can get into the stator windings very quickly, making slotless motors good for applications that require high acceleration and dynamic response.

But slotted motors still hold some advantages. For example, the air gap in a slotted motor is smaller than the air gap in a slotless design (which must accommodate the self-supported winding assembly). This means that the flux density is higher in a slotted motor, and torque production is more effective and efficient.

One way that manufacturers of slotless motors overcome the effects of the bigger air gap is to use larger, stronger permanent magnets in the rotor. But this increases cost. And, the cost to manufacturer the self-supporting winding structure is typically higher than a conventional slotted design. For this reason, the traditional slotted motor design is still the first choice for applications in which smooth running and the elimination of cogging are not critical.

Leave a Reply

You must be logged in to post a comment.