By Megan Ray Nichols • STEM Writer | schooledbyscience.com

By Megan Ray Nichols • STEM Writer | schooledbyscience.com

Motion control is a vital part of equipment operation — and it plays a direct role in automation. Industrial users of assembly and material handling equipment have ever-longer lists of demands, ranging from application-specific equipment designs to smaller and lighter components. Below are three trends in motion control that are driving innovation and increased productivity across the industrial landscape.

Simulation and digital twinning

The move toward “digital everything” has spurred a significant change in motion control: simulation. Machine development is a lengthy and complex process involving detailed drawings and design work, followed by prototyping and testing of the new machine. Naturally, the design phase can’t foresee every surprise and hiccup in the design — and that means more prototyping, followed by more testing. Simulation is changing this whole process for OEMs of motion control devices.

Simulation, usually incorporating finite-element modeling, helps engineers test a far more extensive selection of variables, eliminate surprises in the design phase, improve the time to market and better understand the real-world performance of every discrete component. The simulation process culminates in a working digital model of the final product which people can study in detail, safely, while observing the effect of resizing gearboxes and motors and ultimately dialing in the ideal balance between material costs, optimal performance and machine footprint.

Simulation through “digital twinning” isn’t just useful for designing and developing new products, either — engineers can also use simulations to observe the effect of new controller algorithms or equipment upgrades. It also makes it easier to test new functions and ultimately deliver application-specific and niche functionality to the user.

Consider 3D printers as an example of why application-specific design through simulation is so valuable. Depositing material layer by layer onto a workpiece is a process that’s highly sensitive to machine vibration. But simulating machine movement during the creation of a new product can tip off engineers about quirks in the product’s design, or in the printer, which can undermine the quality or integrity of the finished product. Even before the prototype is available, engineers can already be making decisions about the product’s design or about choosing different printer equipment.

Frameless motors

In the search for improved equipment efficiency and higher performance and throughput, equipment manufacturers and motor designers increasingly look to frameless motors. Frameless motors deliver a host of competitive advantages, including higher performance in a more compact design, easier customizability and greater flexibility. As manufacturing processes become more specialized and factories require more agile, application-specific machines, frameless motors deliver the means to power these flexible machines and support specialized techniques.

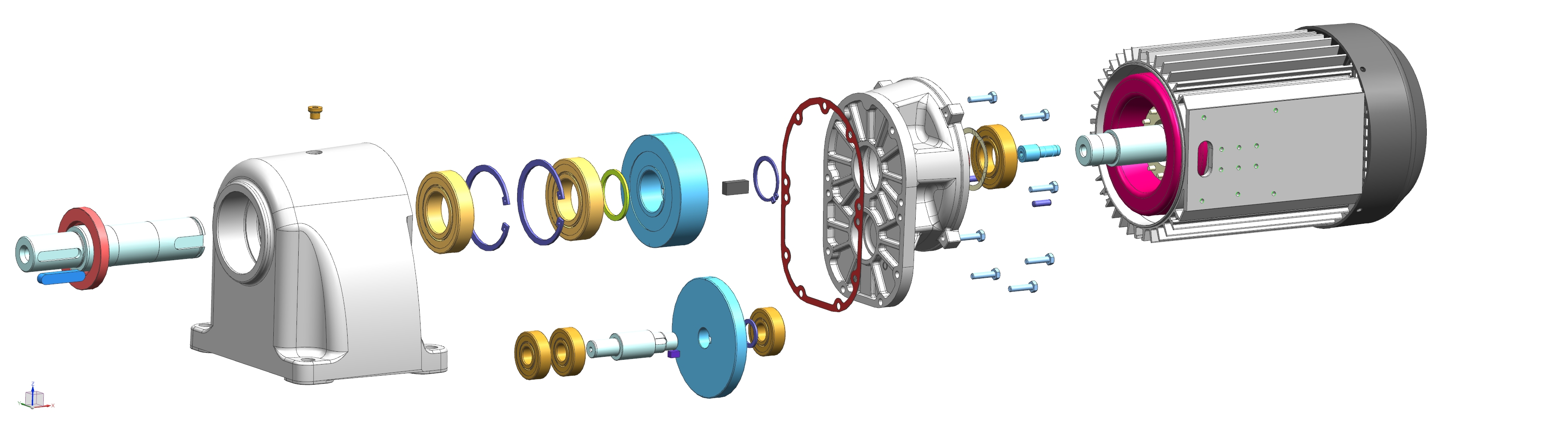

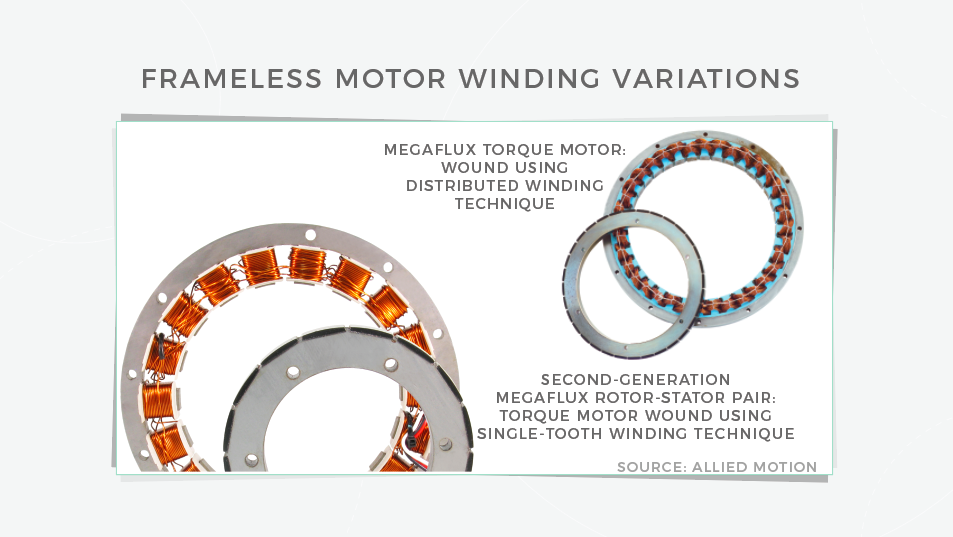

We’re going to see more and more frameless motors in equipment on manufacturing plant floors and especially in robotic arms and other dexterous machines which need a fine-tuned balance between weight and performance. Unlike other motors, frameless motors don’t have a driveshaft. That means they’re not as bulky or heavy as previous-generation motor designs. Instead, OEMs ship them as separate stators and rotors that can incorporate more flexibly and directly into the mechanical structure of a variety of machines.

Because frameless motors don’t need couplings, drive shafts or gearboxes, they also don’t present the same troubles with settling time and potential overshoot housed motors do. This type of motor pairs well with advanced programmable logic controllers that can govern machine movement in up to 96 axes. Frameless motors provide the flexibility to physically do the work all that processing power makes possible.

Ultimately, frameless motors unlock greater flexibility and creativity in machine design. Their design can directly support the application for which they’re destined — unlike framed motors, which generally conform to NEMA and IEC standards and which might not deliver the flexibility and precision required by industry today.

Truly predictive maintenance

Unscheduled downtime is a killer for productivity and profitability. In previous decades, when equipment failed, isolating the problem part required seemingly endless diagnostics work and troubleshooting. And some components aren’t as easy to reach and diagnose as others. The entire process was costly and lengthy.

Predictive maintenance is a trend made possible by digitization and the shift to the Industrial Internet of Things. It means manufacturers and others who rely on heavy equipment uptime can predict which machines are approaching a failure state, then isolate and address those physical assets before they pose a risk to throughput, profits and employee safety.

For instance, drives can deliver real-time data about changes in torque or voltage which might indicate the machine’s lubricant is breaking down or a bearing needs replacement. Thanks to this degree of advanced warning, machine owners can schedule maintenance and repairs at a time when the equipment wouldn’t be in use anyway — and long before a failure that brings production to a standstill and might even cut short the useful lifetime of the machine.

Achieving this requires an understanding of the strength and breakage points of critical machine components like servos, cables and fittings. The rest is thanks to network-connected temperature probes, voltage meters and force sensors, which can cost-effectively integrate into the structure of a variety of machine components.

It can take six months or even longer to “map” complex motion control systems and the equipment they power, and to fully understand what ideal performance looks like during operation. After that, the onboard sensors take over and deliver useful, granular performance data that makes maintenance intervals proactive and truly predictive.

Predictive maintenance, like the other three trends here, isn’t a luxury any longer. These trends, increasingly, are essential competitive advantages for companies that rely on heavy equipment and motion controllers. The coming year will see even higher rates of adoption for these new technologies and techniques.

Megan Ray Nichols is a graduate of Bloomsburg University of Pennsylvania. She’s a professional writer and amateur astronomer.

Leave a Reply

You must be logged in to post a comment.