Since its launch in 2003, the EtherCAT protocol, with “processing on the fly” and data transmission speeds up to 100 Mbit/s, has been widely adopted for automation and process control applications. In 2018, Beckhoff (the developer of EtherCAT), introduced a major performance boost to EtherCAT, in the form of EtherCAT G and EtherCAT G10 — new versions of the EtherCAT protocol that operate at 1 Gbit/s and 10 Gbit/s, respectively.

Beckhoff makes it clear that the new versions are not meant to replace the original 100 Mbit/s EtherCAT. Instead, EtherCAT G and G10 are fully compatible with the original EtherCAT. Devices that were designed for the original 100 Mbit/s EtherCAT can be seamlessly integrated into an EtherCAT G and G10 system. Likewise, EtherCAT G slaves can operate on an EtherCAT master (as long as the master has a Gbit/s port), although EtherCAT G and G10 devices will behave like 100 Mbit/s EtherCAT devices when they’re used in an EtherCAT system — that is, unless the new branch concept is used.

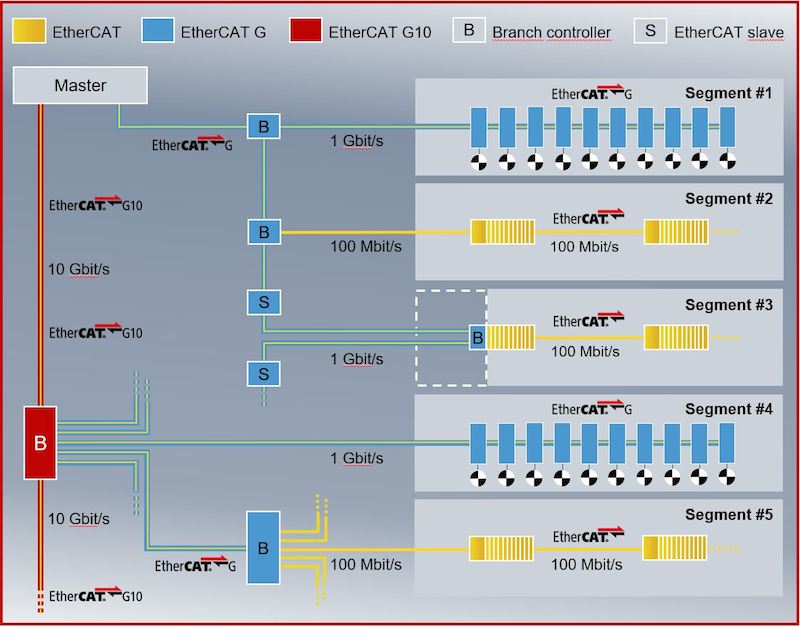

The branch concept allows 100 Mbit/s devices and segments to be integrated into an EtherCAT G or G10 network. A branch controller facilitates parallel operation of 100 Mbit/s segments in a 1 or 10 Gbit/s network by stepping the data rate down from 1 Gbit/s (or 10 Gbit/s) to 100 Mbit/s. These branched networks exhibit significantly shorter signal propagation times — and therefore, shorter communication and cycle times — because each branch is treated as a separate EtherCAT segment which is addressed with a single telegram from the master. Because the various segments are processed in parallel, telegrams from a segment travel directly from the branch controller back to the master at the 1 Gbit/s (or 10 Gbit/s) rate, without having to travel in series through all the other connected segments on the network.

Image credit: Beckhoff Automation

EtherCAT G and G10 were developed with no changes to the EtherCAT protocol or to the EtherCAT master software. They also retain the core features of EtherCAT, including distributed clocks, flexible topology, network-wide diagnostics, and “on-the-fly” telegram processing. The new EtherCAT G and G10 also maintain conformity with the IEEE 802.3 Ethernet standard.

The EtherCAT Technology Group (ETG) officially accepted EtherCAT G as an addition to the EtherCAT standard in 2019.

It’s expected that standard EtherCAT will remain the preferred solution for most industrial applications, while EtherCAT G and G10 will offer the best performance for applications that require extremely high volumes of data, such as those with a large number of motion axes or data-intensive devices such as vision systems and IoT devices. The increased bandwidth offered by the new versions will also benefit these applications. For example, with the branch model, a network could include machine vision systems operating via EtherCAT G or G10, along with slave devices operating via standard 100 Mbit/s EtherCAT. This topology provides the required bandwidth for processing the vision data and the fast communication times needed to process and execute commands resulting from the vision data.

Megabytes and megabits — what’s the difference?

It’s important to note that while most data measurements (such as hard drive capacities) are specified in megabytes per second (typically abbreviated MBps), data transfer speeds are typically specified in megabits per second (typically abbreviated Mbps). The units are different by a factor of eight. In other words, one byte equals eight bits, so one megabyte equals eight megabits.

Leave a Reply

You must be logged in to post a comment.