PLCs have long been an industry standard in machine control. They range in size and function from the simplest of controllers with the most basic ladder logic instruction set to multi-function complex units that can provide multiple control modes from basic control functions to process control and even motion control functions. (Programmable automation controllers, or PACs, are more advanced controllers that can handle more demanding tasks.)

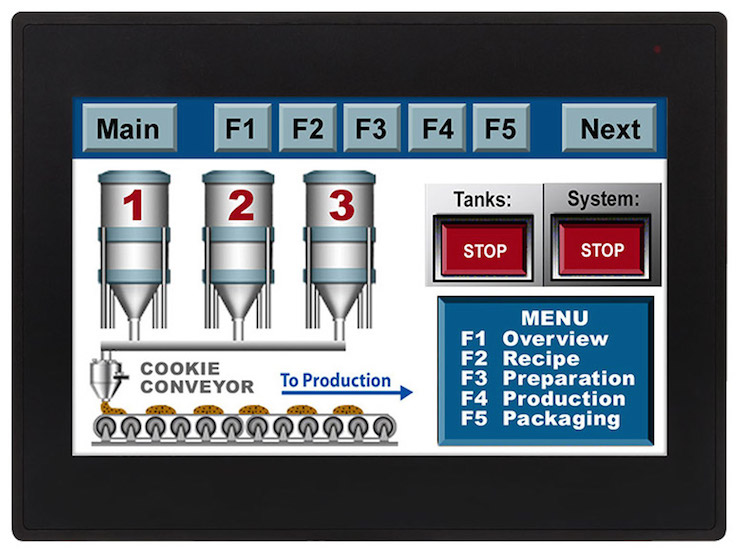

Human-machine interfaces (HMIs) are the basic interface between operators and machines. Recent advances have made them more sophisticated and adaptable in line with technological advancements such as wireless communications, so that they can be accessed and controlled via smart phones and tablets.

Today’s HMIs are powerful enough to take on many of the tasks once handled by control systems themselves, such as actual machine control and processing I/O from sensors and machines. This blending of functions has lead to the rise of HMI-PLC combination units.

As with so much else in the industrial world, integration of previously stand-alone parts is an ongoing trend in the industry as components shrink and are integrated together. For example, so-called integrated motors that combine a motor with a controller, drive and feedback have long been standard in automation applications. So it is with PLCs and HMIs. The same technological trends are at work here, and HMI-PLC combinations are the result.

An HMI-PLC combination unit combines these two functions. This is a natural extension of an ongoing trend, since PLCs have some type of basic interface and on the other hand HMIs have evolved to increasingly be equipped with some basic control functions. Traditional machine control used separate HMI and PLC units. Combination HMI-PLC units integrate both industrially hardened units into a single housing.

Typical HMI-PLC combination units offer basic functions such as data logging, graphing, setting alarms, and monitoring trends, in addition to multiple control functions. They can also function as a web server. There are a number of other benefits that come with integration including fewer parts, decreased cost as well as centralized control and interface capability. Another advantage is that with the units combined there is no separate programming needed for both units but programming is integrated, with a single integrated development environment. They also take up less panel space on a machine and minimize cabling, eliminating the need to wire together a separate PLC and HMI unit.

On the downside, HMI-PLC combination units may be limited in terms of processing power and memory. That is, a separate stand-alone PLC unit or even a PAC often has more computational power and memory storage capability and can therefore handle more demanding control tasks. Combination units may also have fewer I/O options.

The bottom line; smaller applications requiring less complexity can benefit from HMI-PLC combination units because of their lower cost, decreased development time, and smaller footprint, taking up less panel space. For larger equipment and more demanding control applications the separate PLC and HMI approach may still be applicable, or a more powerful PAC may be a more suitable choice.

Leave a Reply

You must be logged in to post a comment.