Industry 4.0 — the intelligent networking of machines and processes for industry with the help of information and communication technology — was initiated by the German government in 2011 (referred to in the German language as Industrie 4.0). Since that time, the principles and technologies behind Industry 4.0 have been adopted to varying degrees by manufacturers around the globe, giving rise to what is often termed the Fourth Industrial Revolution.

But a concept as broad and complex as Industry 4.0 requires a high degree of standardization for its full benefit to be realized. Everything from the overall system landscape to the communication structure needs to be well-defined and agreed upon by all stakeholders. To achieve this, the Platform Industrie 4.0 working group on reference architectures, standards, and norms has introduced the Reference Architectural Model Industry 4.0, or RAMI 4.0.

The purpose of RAMI 4.0 first and foremost is to ensure that all participants in Industry 4.0 discussions — especially those involved in its deployment — have a common understanding of what Industry 4.0 entails, the function of each element, and the interfaces between them.

The three dimensions of RAMI 4.0

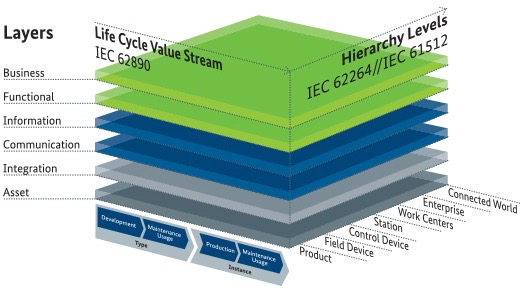

RAMI 4.0 is similar to the 7-layer OSI model for network protocols. But Industry 4.0 involves all aspects of manufacturing, whereas the OSI model only addresses networking. To account for this increased complexity, RAMI 4.0 is depicted as a cube, or 3D map, that shows the elements and concepts of Industry 4.0 and how they relate to one another.

The cube is structured with the first dimension (first horizontal axis) representing the product life cycle and value stream, the second dimension (vertical axis) representing the interoperability layers, and the third dimension (the second horizontal axis) representing the hierarchy levels.

Image credit: Platform Industrie 4.0

Life cycle and value stream

The product life cycle and value stream axis is based on the IEC 62890 standard (currently in development), but in RAMI 4.0, there is a distinction between “types” and “instances.” An asset is considered a “type” during the product design stages (development, simulation, and prototyping, for example), and it becomes an “instance” when actual production begins. In other words, products are instances of a type.

Interoperability layers

The vertical axis shows the interoperability layers (also referred to as the architectural layers), depicting the IT structure of Industry 4.0. There are six interoperability layers (from the top down) — business, functional, information, communication, integration, and asset — covering everything from business processes to communication standards to the physical components and humans that are part of the process.

Hierarchy levels

The hierarchy levels (modeled after the IEC 62264 standard and similar to the automation pyramid) represent different participants within the network — products, field devices, control devices, stations, work centers, the enterprise, and the connected world.

It’s important to note that in RAMI 4.0 (and, hence in Industry 4.0), products are a part of the network and can communicate across the network, the same as other participants. Also, the hierarchy has been extended all the way up to the “connected world,” which represents the connection to the Internet of Things (IoT).

The digital representation of an asset: The administration shell

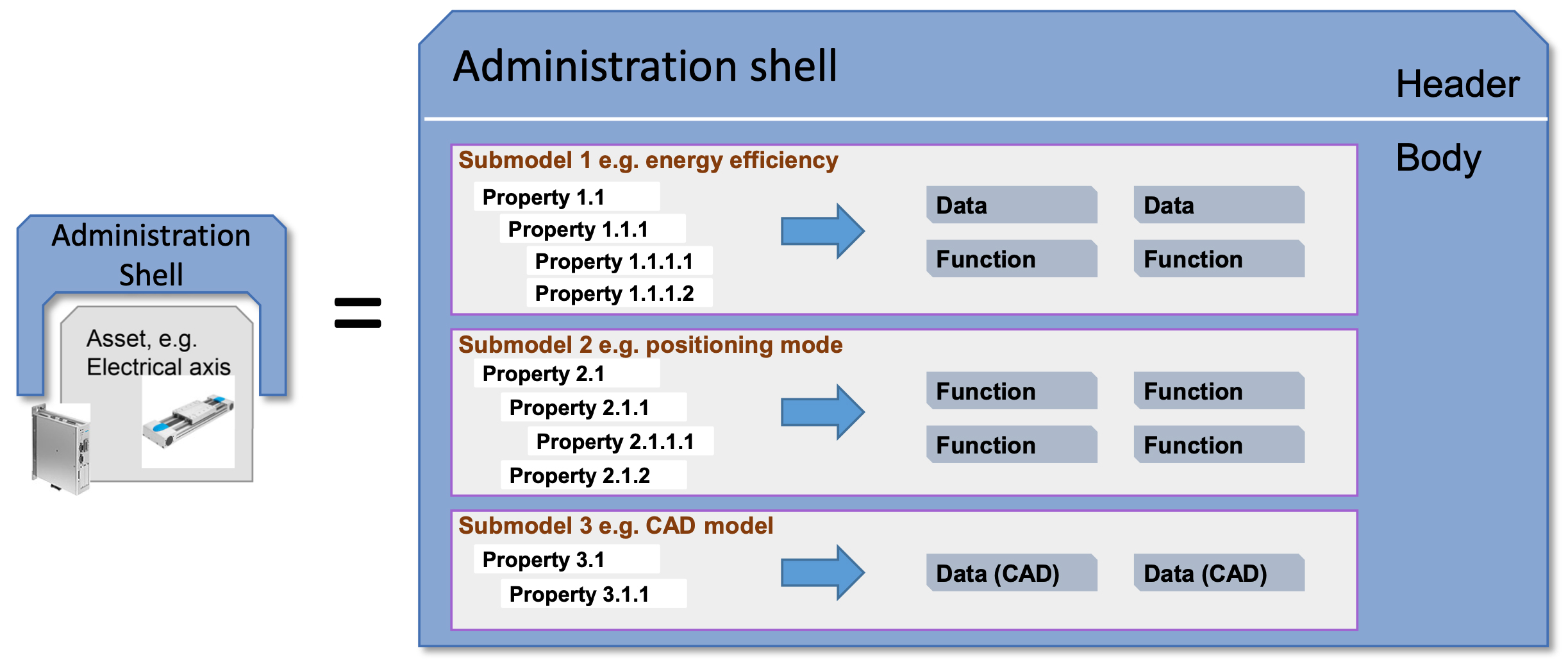

Industry 4.0 defines an asset as “anything that requires a connection for the Industry 4.0 solution,” including machines, machine components, materials, products, drawings, wiring diagrams, and even contracts and orders. All these various assets must be identifiable — other devices, systems, and services within the Industry 4.0 network must be able to read and understand the asset’s type, operational and technical data, status, and other asset-specific information. To accomplish this, RAMI 4.0 introduces the asset administration shell (also referred to as simply the “administration shell” or “AAS”).

The asset is the physical part, and the administration shell is the digital part, storing identification, operational, technical, and status information about the asset over its entire lifecycle. The asset administration shell provides a standardized, secure communication interface between the asset and the Industry 4.0 network.

Image credit: ZVEI

Leave a Reply

You must be logged in to post a comment.