Ultrasonic proximity sensors are a common type of proximity sensor used in many manufacturing and automation applications. Mainly for object detection and distance measurement, they’re commonly used in food and beverage processing and various packaging applications. Ultrasonic sensors work by using sound frequencies higher than the audible limit of human hearing (around 20 kHz), which is typically in the range of 25 to 50 kHz.

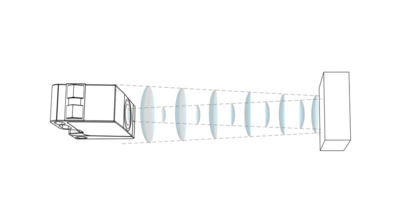

The basic physical principle of ultrasonic sensing is that the sensor sends out an ultrasonic pulse and receives a pulse back. Using the time difference between the sent and received signal, the distance to the object can be determined. A common design is to build both the transmitter and the receiver into the same physical housing, although they can also be housed in separate units like certain photoelectric sensors with separate emitters and detectors. Housing the transmitter and receiver in the same unit simplifies installation and cabling.

Because ultrasonic proximity sensors use sound rather than light, they can be used where photoelectric sensors have difficulty, such as in detecting clear plastic objects and labels, highly reflective surfaces that throw off optical sensors, or even liquid levels. They’re also immune to common contaminants such as dust, moisture, and ambient light.

Depending on the application requirement, ultrasonic proximity sensors can be installed and operated in a number of different ways. In fact, because the sensing itself is based on emission of waves and their detection, the ways they can be installed parallel those of photoelectric sensors. That is, setups can include simple reflection of sound waves (as in retro-reflective modes) or they can be setup for through-beam type sensing or a diffuse mode.

For most sensing applications using ultrasonic sensors, it’s desirable to have a fairly narrow output beam in order to avoid reflections that could produce inaccurate readings. A wider beam will disperse over a greater area and may cause interference patterns that could cause inaccurate readings.

Besides beam angle, consider other parameters such as the optimal sensing mode for the application, the required measurement range, the output type (analog or switch/relay output), as well as the size, shape, and material of the housing.

Leave a Reply

You must be logged in to post a comment.