Machines and equipment placed on the EU market must be CE-marked, indicating conformity with the essential safety and health requirements of the Machinery Directive.

The Machinery Directive 2006/42/EC is a set of legal requirements for manufacturers and distributors of machines in or to the EU market that ensures the safety of operators, maintenance personnel, equipment, and the environment. According to the European Commission, the Machinery Directive “promotes the free movement of machinery within the single market” and “guarantees a high level of protection for EU workers and its citizens.”

In addition to meeting essential health and safety requirements in the design and construction of their equipment, in order to be in compliance with the Machinery Directive, manufacturers must also prepare technical documentation (including safety-related design documents) relevant to conformity with the Directive, and they must supply operating instructions in the official language of the country of use.

When developing machines and equipment according to the Machinery Directive, manufacturers follow standards such as EN/ISO 13849-1 and EN/IEC 62061. These harmonized standards have been developed to describe the requirements of the Machinery Directive in detail, allowing manufacturers to meet the objectives of the directive. The application of these standards provides a “presumption of conformity” with the requirements of the Machinery Directive.

The Machinery Directive recognizes that some types of equipment and machinery (such as actuators and robots) cannot perform a specific function on their own and must be installed in or combined with other equipment to form a complete machine. To address these “partly-completed” machines, the Directive specifies that the manufacturer must meet all reasonably achievable requirements of the Directive.

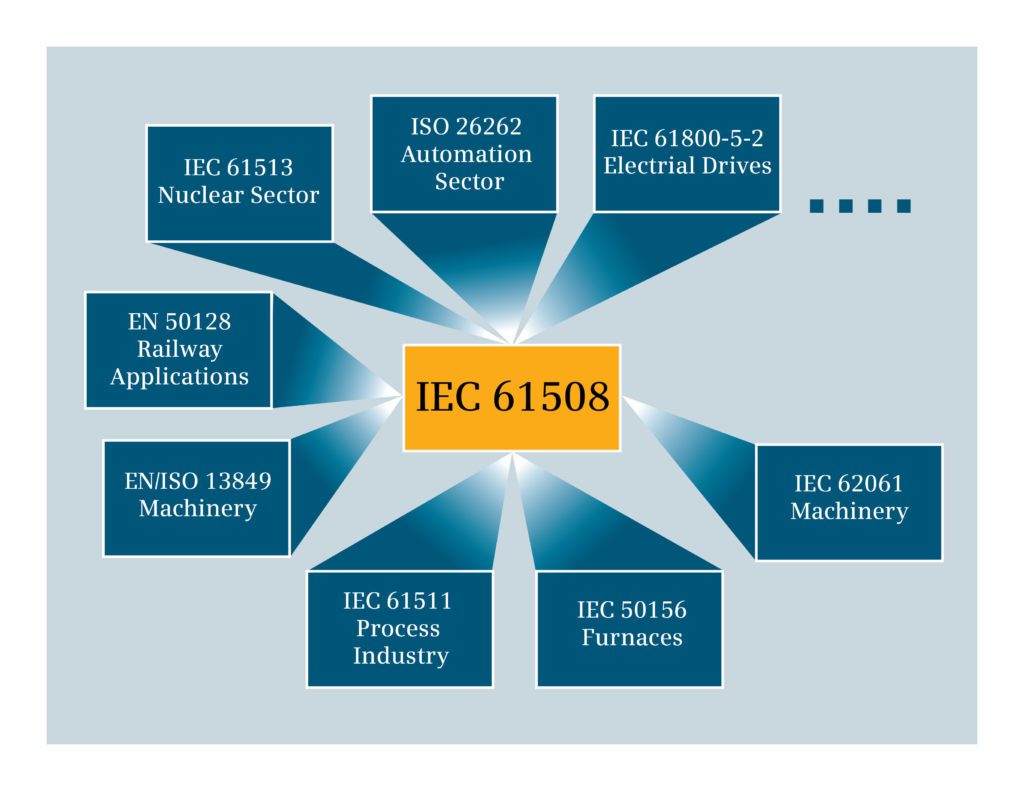

The standard IEC 61508, Functional Safety of Electrical, Electronic, and Programmable Electronic Systems, also addresses machine safety. However, this standard is a generic, or “umbrella,” standard for functional safety that is application-independent. Although IEC 61508 is referenced by other IEC and ISO standards, it is not a harmonized standard, so compliance with IEC 61508 does not provide a “presumption of conformity” to the Machinery Directive. However, compliance with IEC 61508 can be used to support conformity with specific requirements of the Directive.

The harmonized standard EN/IEC 62061, Safety of machinery – Functional Safety of Safety-related Electrical, Electronic, and Programmable Electronic Control Systems, is derived from IEC 61508 but adapts the safety requirements to the needs of industrial machinery.

Image credit: Siemens

Motion systems and functional safety

Image credit: SICK

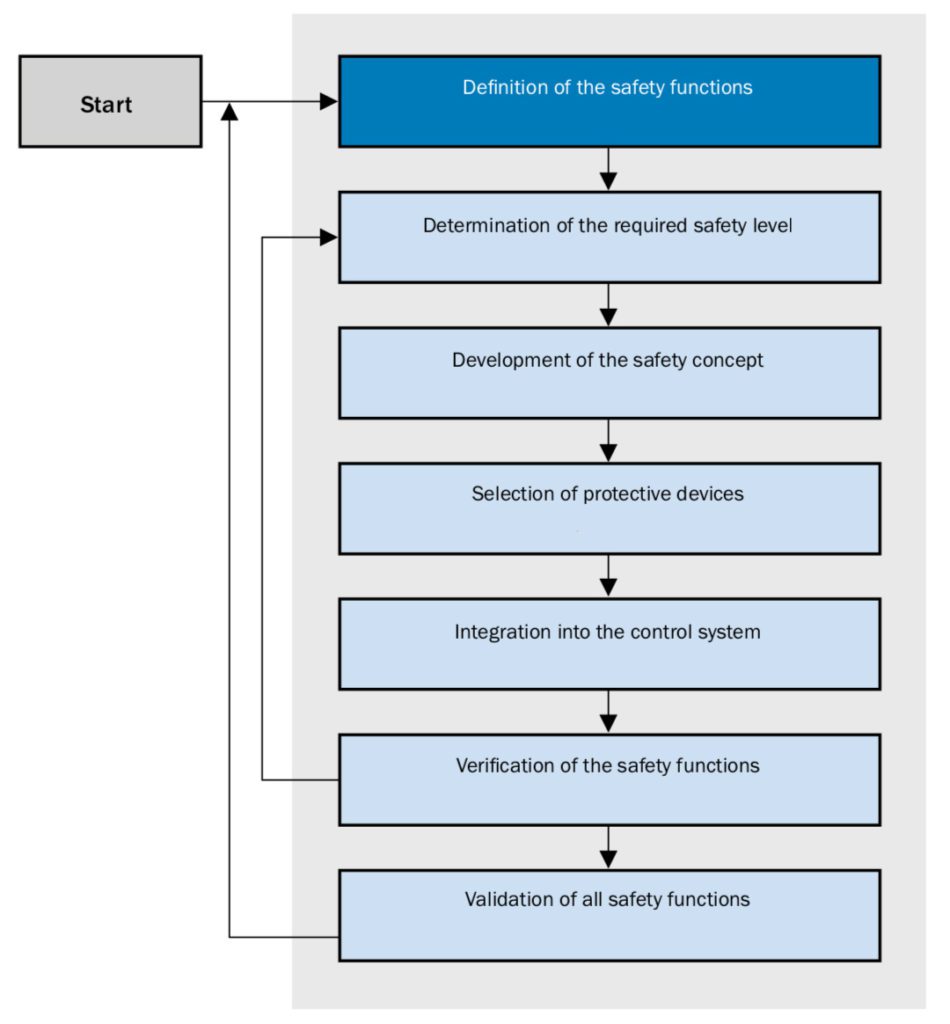

The Machinery Directive requires that a risk assessment be performed to identify possible hazards (electrical, mechanical, noise, and radiation, for example) in all phases of the machine’s service life, from transport and installation to dismantling and disposal. This is followed by the implementation of risk reduction measures, which can be accomplished via safe design or via technical protective measures, until only acceptable residual risks remain.

Technical protective measures include devices such as light curtains, covers, doors, and systems to monitor the movement of the machine. When the effectiveness of a technical protective measure depends on the correct function of the control system, functional safety principles and measures must be applied. Functional safety requires that an appropriate safety level be determined, implemented, and verified.

Examples of safety functions include methods to prevent access (temporarily or permanently), initiate a stop, prevent an unexpected startup, and monitor machine parameters to ensure the machine doesn’t exceed safety-related limits, among others. Drives, such as servo drives, play an integral role in functional safety. To address the requirements of the Machinery Directive, many drives and control devices (such as PLCs) now have integrated safety functions to ensure safe braking and stopping or safe movement of the machine during operation.

Leave a Reply

You must be logged in to post a comment.