Roller chains are one of the most common types of transport media for conveying systems. While they’re available in many designs and variations to meet different application requirements, they all have one thing in common. To specify a roller chain, you need three basic dimensions:

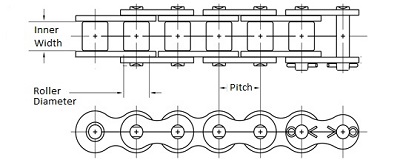

The chain pitch … the roller diameter … and the width between inner link plates.

In general terms, pitch can be specified with reference to any feature — such as a hole or an edge — that is repeatable on each adjacent part.

In terms of conveyor chain, pitch is usually defined as the distance between links, as measured from the center of the roller pin on one link to the center of the roller pin on the next link.

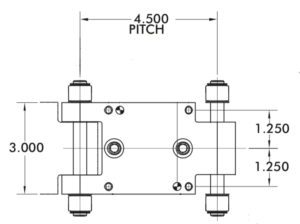

Note that some precision link conveyors refer to the pitch as the link size.

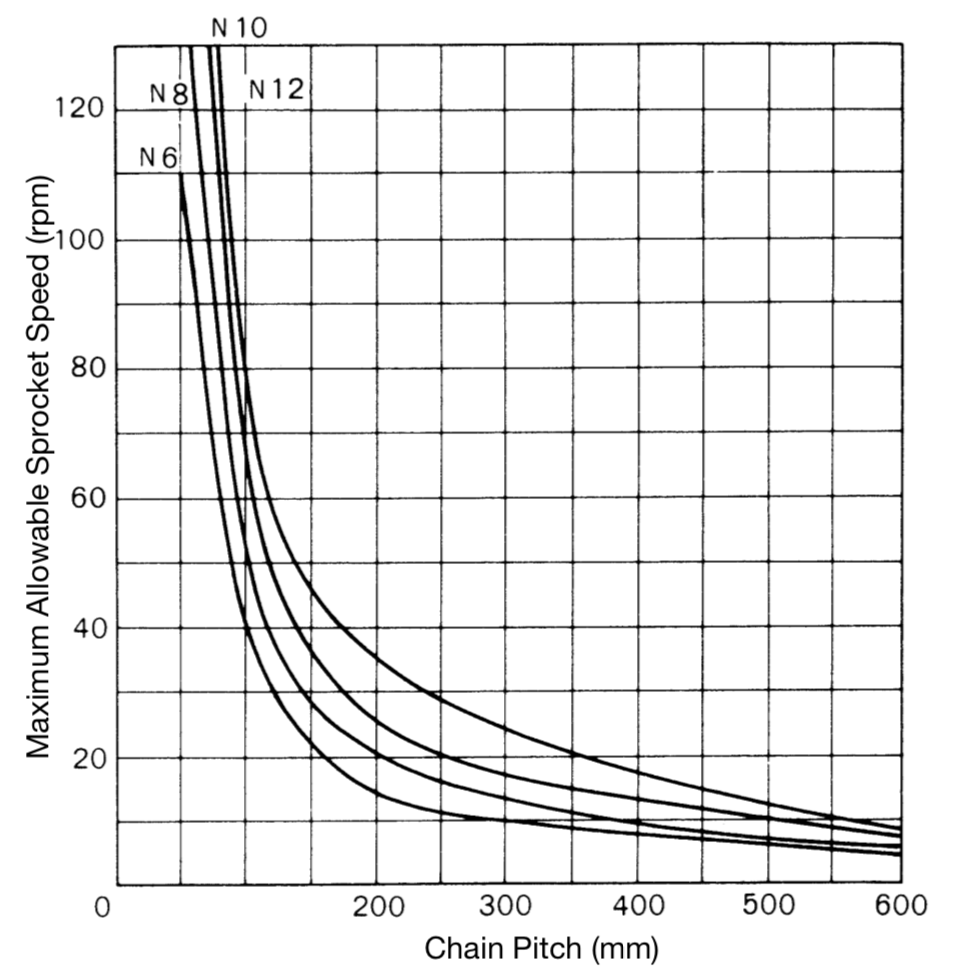

The pitch of a conveyor chain or link is a determining factor for several performance characteristics of the conveyor. For example, there’s an inverse relationship between sprocket speed and chain pitch. Smaller pitch chains generally allow the sprocket to run at a higher rotational speed.

![]()

n = sprocket speed (rpm)

V = chain speed (m/min)

P = chain pitch (mm)

N = number of sprocket teeth

Also note that the smaller the pitch, the more teeth will be needed on the chain sprocket. And a higher number of sprocket teeth means that more chain links will be engaged during motion. This allows the chain to travel with less speed fluctuation and a smaller articulating angle, producing less vibration and better smoothness of motion.

More sprocket-link engagement also provides less wear between the chain bushing and pin, meaning longer life of the chain. For these reasons, manufacturers generally recommend using the smallest chain pitch that satisfies the application conditions.

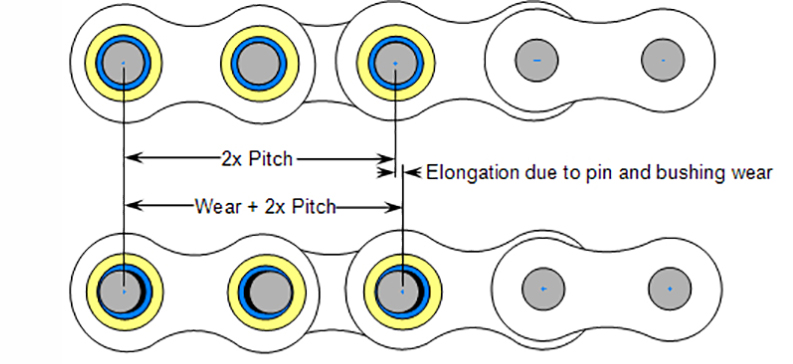

Wear to the pins and bushings can also cause the pitch to elongate. Manufacturers typically recommend replacing the chain when the extension of the pitch length reaches 2 to 3 percent of the normal pitch value.

Leave a Reply

You must be logged in to post a comment.