Belt and pulley drives are used in a wide range of industrial applications. In putting together a system properly, factors to consider include correctly sizing the pulleys and the belt. Part of that correct sizing involves the depth of engagement between the belt and the pulley.

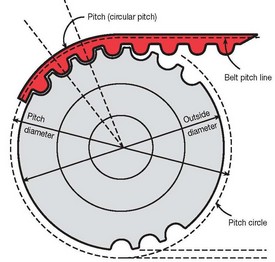

Common belt types include V belts and synchronous belts. Regardless of belt type, to ensure proper engagement, the sprocket pitch circle should line up with the belt pitch line. In other words, the belt must have the same pitch as the pulley in order for both to mesh properly.

Correct or proper engagement leads to the best overall performance results. When pulley teeth correctly mesh with belts they reduce belt wear, thereby prolonging useful life. The wrong combination of belt and pulley and poor meshing of belt teeth with pulley grooves can lead to problems like slip that can cause unreliable speed output.

Common V-belts are a good example. For such belts a key performance indicator is the amount of grip between the belt and pulley, which determines how much power is transmitted. There are three factors involved here; the area of contact, the belt tension and the friction between the belt and pulley. For all of these factors, proper depth of engagement between the belt and pulley is critical.

Leave a Reply

You must be logged in to post a comment.