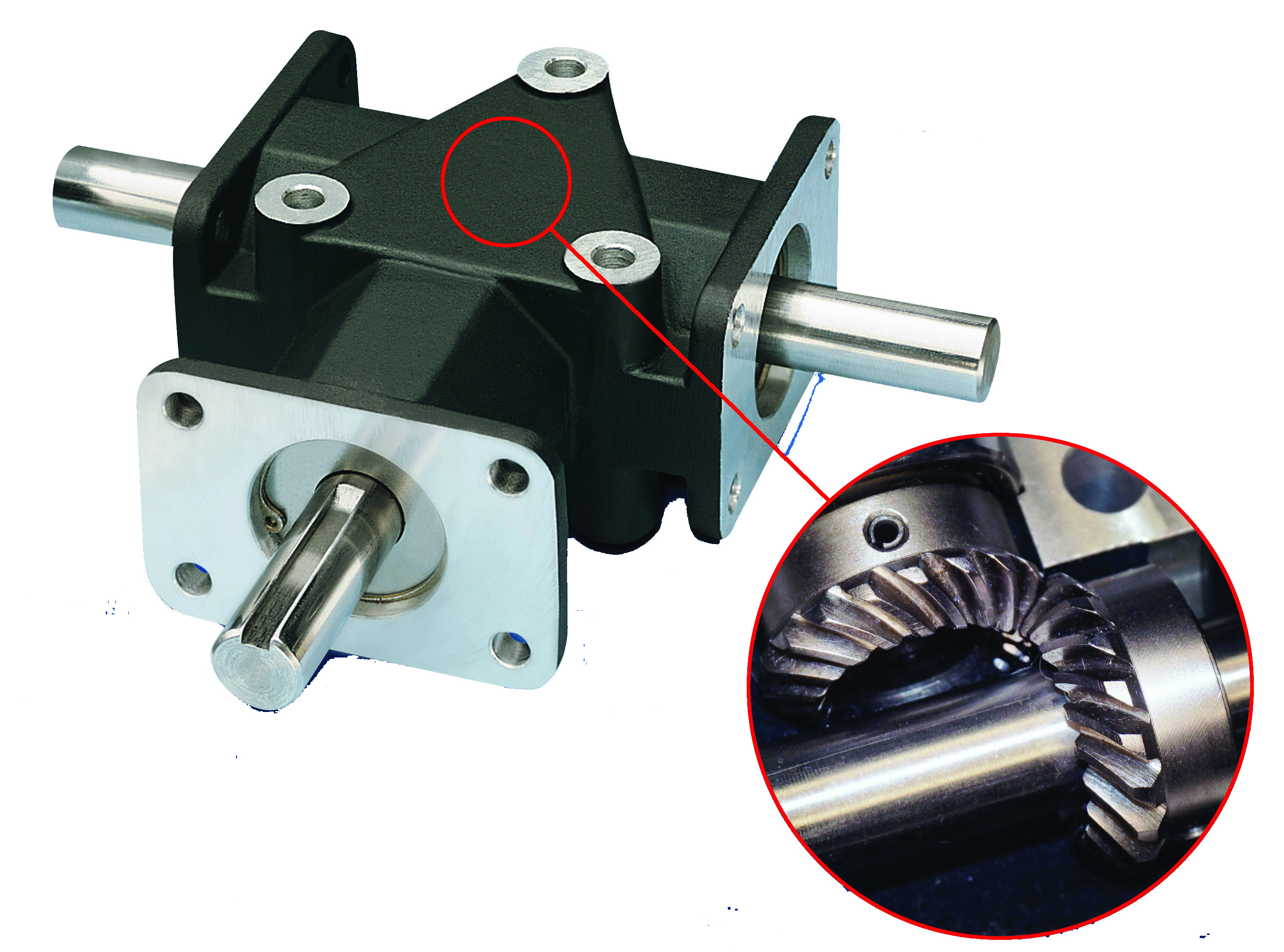

Lubricated for life with Beacon 325 premium grade grease, Zero-Max Crown drives feature heat treated AGMA Class 10 spiral bevel gears. This combination of bearing design and lubrication formulation ensures long-term, maintenance free operation for high performance, industrial applications. The drives feature long-life, precision hardened and ground ball bearings handling speeds up to 2000 rpm in most operating environments. The internal gears are permanently mounted to the shafts with the use of a press-fit and locking pins. This provides a very resilient and durable connection for use in heavy load applications while needing no maintenance.

Lubrication with Beacon 325 grease ensures optimum performance in temperature ranges from -50° C to +120° C without evaporation. This is especially important in sealed for life systems using motors, generators and similar equipment in industrial applications.

Zero-Max ensures their drives are predictably smooth operating, and similar model sizes have identical performance characteristics when designed into multiple drive setups. To accomplish this, Zero-Max drives are precision assembled for bearing and gear alignment. The drives are prelubricated during assembly, then completely enclosed in a heavy-duty anodized aluminum housing. This design ensures that internal gears stay permanently aligned, lubricated and free of contamination from outside debris.

Zero-Max Crown drives are suitable for a wide range of machine applications including food processing, packaging and material handling systems. Available in many sizes and models, they are suitable for myriad horsepower, torque and shaft speed requirements. Standard two and three-way models are available with 1:1 and 2:1 speed ratios in shaft diameter combinations of 3/8, 1/2, 5/8 and 3/4 in.

For more information, visit www.zero-max.com —or call (800) 533-1731 for a brochure.

Leave a Reply

You must be logged in to post a comment.