Couplings for servo applications usually connect precision drives to sensitive loads, so they cannot induce any error. That’s why servocouplings should be zero backlash — to prevent issues with timing and predictability (not to mention failures due to hammering on reversing axes). Couplings for servo applications must also have high torsional stiffness while imparting slight forgiveness of misalignment (within specifications) of rotating shafts … even while holding transmitted rpm steady to motor output rpm.

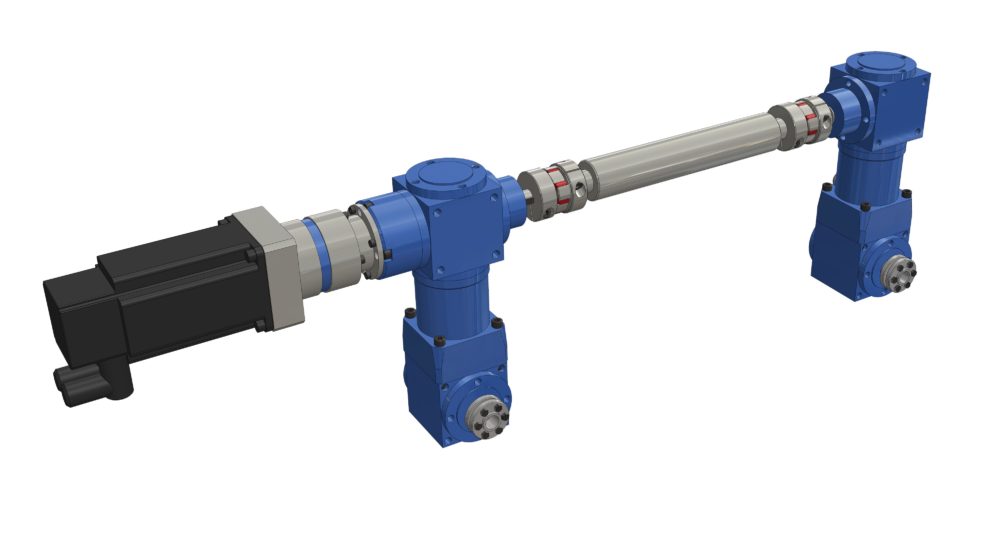

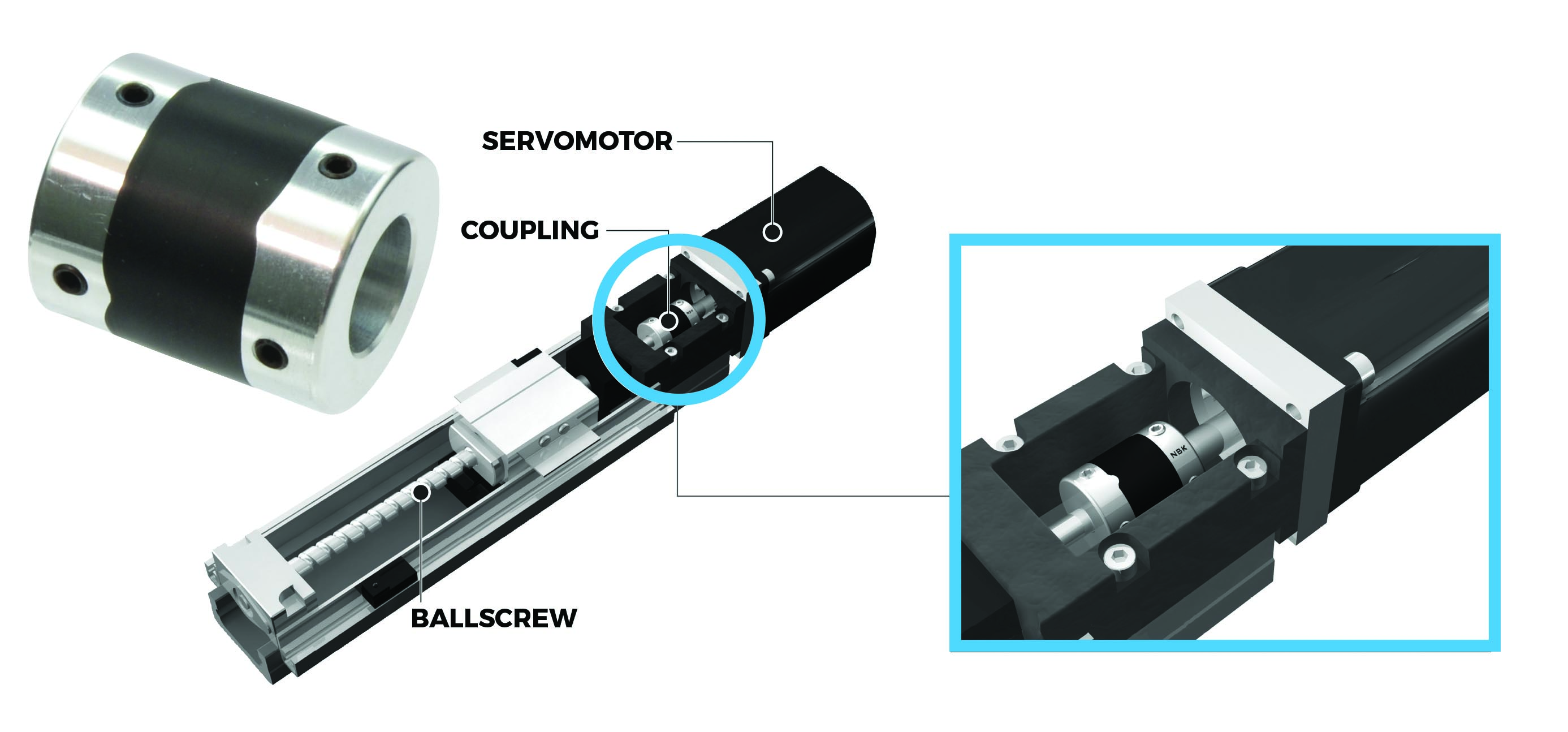

But these are just a couple servocoupling considerations. Consider a typical application for servocouplings — to connect a servomotor to a ballscrew. Here, couplings with low inertia let the axis deliver faster acceleration and deceleration without unnecessarily degrading overall system efficiency.

In fact, couplings for servo designs must often compensate for subtle power-transmission issues to minimize errors down to 1 arc-min. or lower. That’s especially true where servo systems take the form of exacting positioning axes.

Here’s a more complete list of parameters to consider for proper coupling operation in such designs:

1. Coupling type

Couplings shouldn’t be the last motion component specified because proper servo-machine function relies on having a suitable coupling in place. Torsionally rigid options (ideal for motion designs) include specialty bellows couplings, rubber-jaw couplings, and disc couplings.

Curved-jaw couplings have good damping characteristics to optimize performance of axes with quick acceleration and deceleration. Elsewhere, both disc-type couplings and certain bellows couplings excel on high-speed axes. Other offerings abound to serve other design objectives. One caveat on coupling type though: Never use rigid couplings to replace flexible servocouplings on axes where the latter seem to fail frequently. Here, this issue is most likely insufficient alignment between the motor-output shaft and next component in the powertrain. There’s sometimes a misconception that rigid couplings are exceptionally strong, so can address issues in such situations. The fact is that rigid couplings only work when shafts are perfectly aligned, because these couplings transmit to connected motion components (potentially extreme) forces that arise from misalignment.

2. Sizing for torque (and speed)

After specifying the coupling type, the design engineer must select a coupling size. This is heavily dependent on axis speed (rpm), the levels of torque the axis must transmit, and the service factor the application requires. Axes that transmit steady torque are simpler to specify; in contrast, axes that transmit variable torque need additional consideration. Here, define the application’s average operating torque and the peak torque. (Also consider the parameters listed in “Ability to handle reversals” below.)

One tip to avoid servocoupling oversizing: Quantify actual system requirements and base coupling selection on those values — and avoid defining a whole axis by the connected gearmotor’s peak torque output.

3. Coupling stiffness

Along with exacting control of position, force, or output velocity, it’s often essential to maintain high efficiency. Couplings that exhibit windup or backlash degrade this efficiency because they must overcome load inertia every move cycle. This can be a significant drawback in some setups … which is why (especially on axes employing rigid couplings) couplings should be prevented from inadvertently functioning as flywheels.

Note that if a coupling’s torsional stiffness is insufficient, other system functions must compensate. One standard solution is to adjust PID controls and reduce servo gain, though that degrades system response and performance. In contrast, excessive torsional stiffness compromises the ability of an axis to withstand quickly reversing loads. That’s because servocouplings with excessive stiffness can be brittle and prone to failure on demanding axes that must make frequent and sudden directional reversals.

Servo-application tip: Balance coupling characteristics for stiffness. Excessive torsional stiffness may induce premature failure. On the other hand, axes that must hold timing (as for positioning commands) benefit from incorporation of torsionally stiff couplings.

4. Coupling inertia

As mentioned, this is an important parameter for a few reasons. Applications with particularly aggressive motion profiles rely on low servocoupling inertia most of all.

5. Coupling damping capabilities

Disc couplings, certain bellows couplings, and high-gain rubber-type couplings are all options for coupling-based damping in servo applications. In fact, the most demanding servo applications have in recent years spurred improved response frequencies … but vibration (and hunting) arise with high gain settings on assemblies using torsionally stiff couplings. Refer to Servo couplings: Stiffness, damping, hunting, and stabilization considerations at couplingtips.com for more on this.

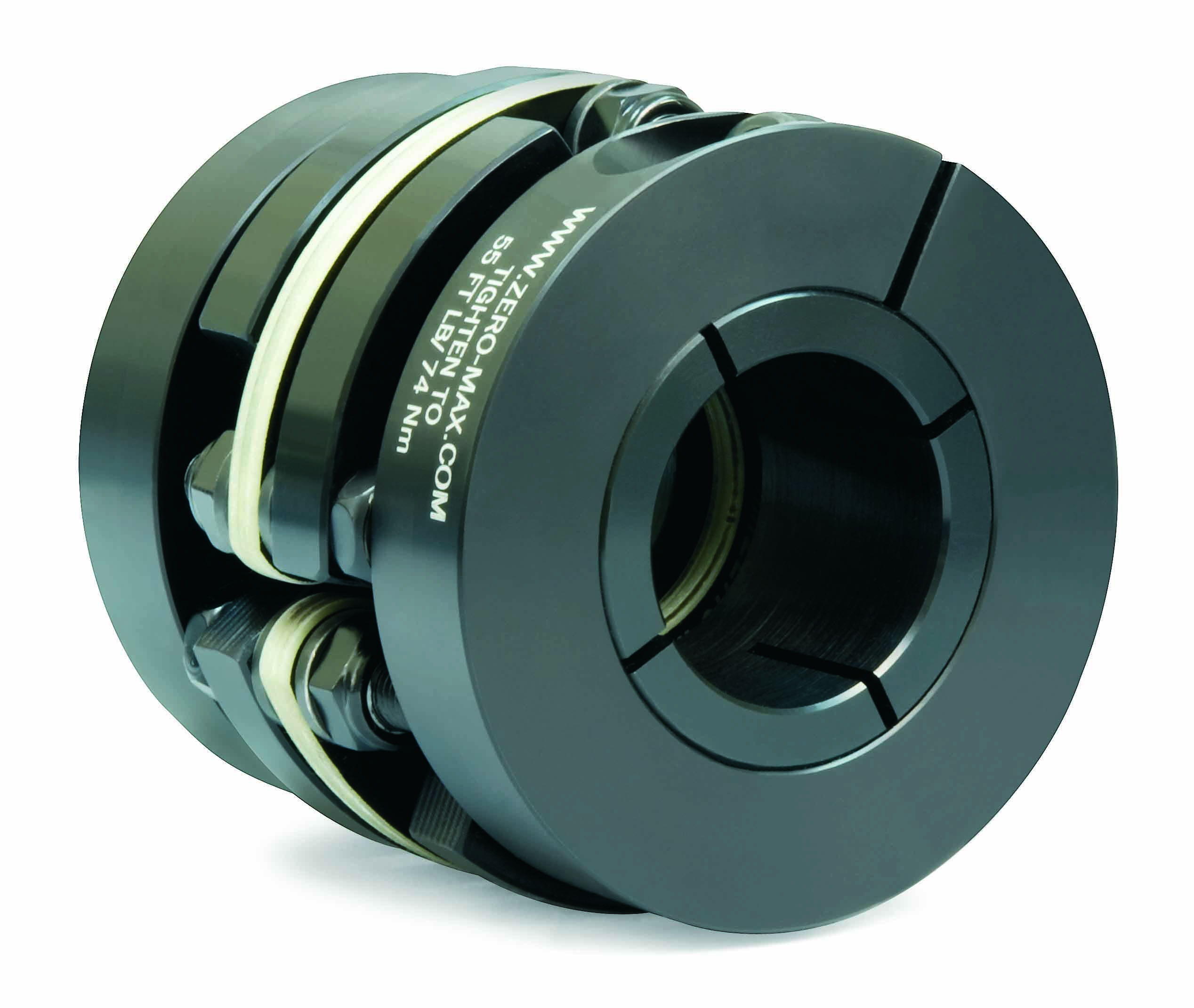

6. Shaft connections

Most servocouplings connect shafts with clamping or locking mechanisms (and not keyways). Though keyways are often offered as an option to prevent shaft slippage, the truth is that they can be a liability — adding concentrations of stresses in shaft connections, unnecessary cost, risk of imbalance, and other potential drawbacks. Read Conical clamping hubs add protection to high torque applications for more on this.

7. Ability to handle reversals

Servo applications that must make quick directional changes require special consideration. Here, consider torque associated with system inertia starting and stopping. Service factors can often quantify the effect this value will have on assembly dynamics. Another aspect of reversing loads to consider is coupling-material fatigue. Keep in mind that some servocouplings that excel in regular applications can fail within weeks (or sooner) when forced to transmit power under reversing conditions.

8. Function to protect more expensive subcomponents

Though system failures are best avoided, couplings can be designed to protect the axis actuator or motor and gearbox by breaking if there is a machine crash or catastrophic overload. That’s especially useful in high-speed servo applications where drive-based current limits aren’t fast enough to address existing kinetic energy associated with the drivetrain and load upon a jam or sudden impact.

9. A realistic understanding of allowable misalignment

Flexible couplings for servo applications do accommodate misalignment. However, OEMs must be realistic about the level of permissible misalignment for a given axis — and specify assembly techniques and mounting that ensure levels never exceed the rating of the coupling. Otherwise, coupling or another component failure may occur.

Leave a Reply

You must be logged in to post a comment.