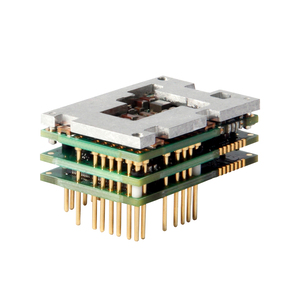

The FE060-25-EM is the first servo drive of the new FlexPro digital drive family from ADVANCED Motion Controls (AMC). Designed with compact form and power density in mind, the micro-sized FE060-25-EM can outperform larger-sized digital servo drives and still be integrated into tight spaces.

At just 1.5 x 1 x 0.6 in. (38 x 25 x 16 mm) in size, the footprint of the drive is approximately the same as two standard postage stamps. In other words, four of these drives can fit on a standard business card. Even with its small size, the FE060-25-EM can supply brushed, brushless, stepper, and linear servo motors with up to 25 A continuous current and 50 A peak current.

AMC_Image_FE060-25-EM features include:

- 10 to 55 Vdc supply voltage

- Highest power density servo drive from ADVANCED Motion Controls to date

- EtherCAT Communication

- Incremental encoder and BISS C-mode feedback

- Torque, velocity, and position operating modes

- Configuration and full loop tuning

- IMPACT architecture

IMPACT (Integrated Motion Platform And Control Technology) is the architecture that makes AMC’s FlexPro drives possible. The stacking of circuit boards with creative selection and placement of high-power components allows for much higher power density than previously produced servo drives.

A developer version is available for proof-of-concept and testing purposes – part number FD060-25-EM. It comes with an FE060-25-EM soldered to a larger board equipped with various connectors for simplified interfacing.

The small size of the FE060-25-EM makes it perfect for cobots (collaborative robots), AGVs, portable devices, lab and warehouse automation, military equipment, and any other integrated design.

For more information, visit www.a-m-c.com.

Leave a Reply

You must be logged in to post a comment.