Bodine Electric Co. has just announced sixty (60) new 33A7-25H2 and 33A7-30H3 hollow-shaft right-angle hypoid PMDC gearmotors. These integral geared motors combine Bodine’s high-performance type 33A7 permanent magnet dc motor with two new hypoid gearheads. They are a suitable drive solution for applications needing compact size, quiet operation, high torque density, and low energy consumption.

Typical applications include conveyors, pumps, packaging, industrial automation, and wide range of solar and battery-powered motion designs.

More efficient than comparable worm-gear models, Bodine’s new hypoid gearmotors can deliver up to 1535 lb-in. (173 Nm) torque while using 40 to 60% less energy than a same-size worm gearmotor. Side-by-side tests have shown that hypoid gearmotors can run as much as 15% cooler than worm-gear gearboxes, resulting in lower power consumption and longer lubricant life.

These hypoid gearmotors can deliver the same torque with a smaller more efficient motor compared to worm-gear boxes — resulting in a smaller mounting footprint. Plus the hollow-shaft design eliminates expensive shaft couplings and mounting hardware. Hardened steel gears ensure long life and maximum performance.

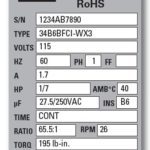

This initial hypoid-gearmotor product launch includes 60 standard models with gear ratios from 5:1 to 240:1. The manufacturer offers 35 standard models with a smaller 25H2 gearhead featuring a 1.00 inch hollow shaft and ratios from 5:1 to 60:1. The larger 30H3 gearhead features a 1.25 hollow shaft and covers the gear ratios of 80:1 to 240:1. Rated torque ranges from 20 lb-in. (2.2 Nm) to 1535 lb-in. (173 Nm).

The motors at the core of these Bodine hypoid gearmotors include windings that are:

• Low-voltage (12 or 24 Vdc)

• SCR rated (90 Vdc or 180 Vdc)

• Standard (130 Vdc) windings

Hypoid gearmotor accessories for this line include shaft kits, shaft cover kits for the non-extension side, base and foot mount brackets for both gearheads, and an optional screw-in encoder shaft and encoder mounting options.

Bodine PMDC Hypoid gearmotors and their corresponding accessory kits are available through Bodine’s extensive distributor network or from the Bodine web site. Custom options are available to qualified OEMs. Typical OEM modifications include factory installed encoders or brakes, custom windings or wire harnesses, application-specific mounting options, or higher degrees of environmental protection.

Bodine Electric Co. offers more than 1,300 standard stock products, and thousands of custom designed fractional horsepower (FHP) gearmotors, motors, and motion controls — including variable speed and fixed speed ac, brushless dc, and permanent magnet dc variations. Bodine Electric is headquartered in Northfield, Ill. with manufacturing and assembly operations in Peosta, Iowa. For more information, visit bodine-electric.com.

Leave a Reply

You must be logged in to post a comment.