Celera Motion, a business unit of Novanta Inc., announces the new Everest S, the latest addition to the company’s Everest Series, which is about 30% smaller than its predecessor. The EtherCAT and CANopen versions deliver bus latency reduced to 1 cycle. The Everest S includes all the best features of other Everest servo drives — […]

Servo Drives

Mitsubishi Electric Automation at Automate 2022

Mitsubishi Electric Automation will exhibit at Automate 2022 in Detroit to highlight solutions for a wide variety of applications and industries. The theme of the exhibit is “better together”, which shows creative solutions developed by a number of companies based on Mitsubishi Electric automation products. The “better together” approach includes an in-booth experience centered on […]

Part two of three: Servo-system regenerative resistor types and accessories

In the first installment of this series, we explained the regenerative-power requirements for the controlled motion of servomotor systems. Here we detail common electrical protection circuitry. By Hurley Gill • Senior applications and systems engineer | Kollmorgen Designing a machine with servomotors, drives, and regenerative resistors requires consideration of numerous design factors. These components affect […]

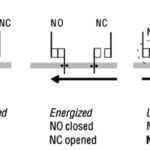

What is external device monitoring and how does it relate to machine safety?

According to the Machinery Directive 2006/42/EC, technical protective measures should be used to reduce risks that cannot be avoided through safe design measures. These technical protective measures include safety devices such as door locks, covers, light curtains, and other equipment that monitors the machine movements. When the safety device controls and external device, such as […]

What machine safety functions address speed, and when are they used?

The Machinery Directive 2006/42/EC states that when a machine manufacturer is unable to eliminate the risks of potential hazardous situations (for example, mechanical hazards such as crushing or cutting) through safe design methods, the next step is to reduce the risks through technical protective measures. These technical measures include protective devices, such as door locks […]

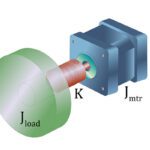

Motion system design: How to manage inertia mismatch

One of the most important parameters when sizing a motion system is the inertia of the load being moved. Regardless of the type of motor being used — AC induction, stepper, brushless DC, or AC servo — the ratio of the load inertia to the motor inertia has an important influence on system performance. If the […]

Common dc bus servo drives for applications with regenerative energy needs

The new MELSERVO-J5D servo amplifiers from Mitsubishi Electric Automation, Inc. offer a unique servo-based solution for applications that need to handle regenerative energy. The common dc bus servo drives are ideal for medium to large servo applications that require multiple drive units capable of managing regenerative energy. Available in 400 V and 1 kW to […]

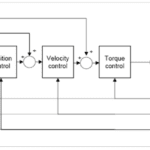

What is cyclic synchronous control (position, velocity, and torque)?

Cyclic synchronous control modes — cyclic synchronous position, cyclic synchronous velocity, and cyclic synchronous torque — are standardized operation modes of drives, defined in the CiA 402 profile specification, CANopen device profile for drives and motion control and included in the IEC 61800-7 standard, Adjustable speed electrical power drive systems — Part 7: Generic interface and use of […]

New micro-sized servo drives rated to 60-A continuous output

ADVANCED Motion Controls has released seven new micro-sized FlexPro servo drives rated to 60 A continuous output. The 60-A continuous current rating is 33% higher than previous models for the same size making these the company’s highest power-density servo drives to date. This offering includes PCB Mount, Machine Embedded and Development Board form factors. PCB […]

AutomationDirect adds new servo systems for motion control applications

AutomationDirect has added LS Electric servo systems that provide extremely accurate motion control and include the most requested features — setup wizards, auto-tuning, built-in indexer, and more — in an extremely cost-effective package. The L7S family of brushless servo systems is fully digital and capable of covering a broad range of motion control applications. There […]