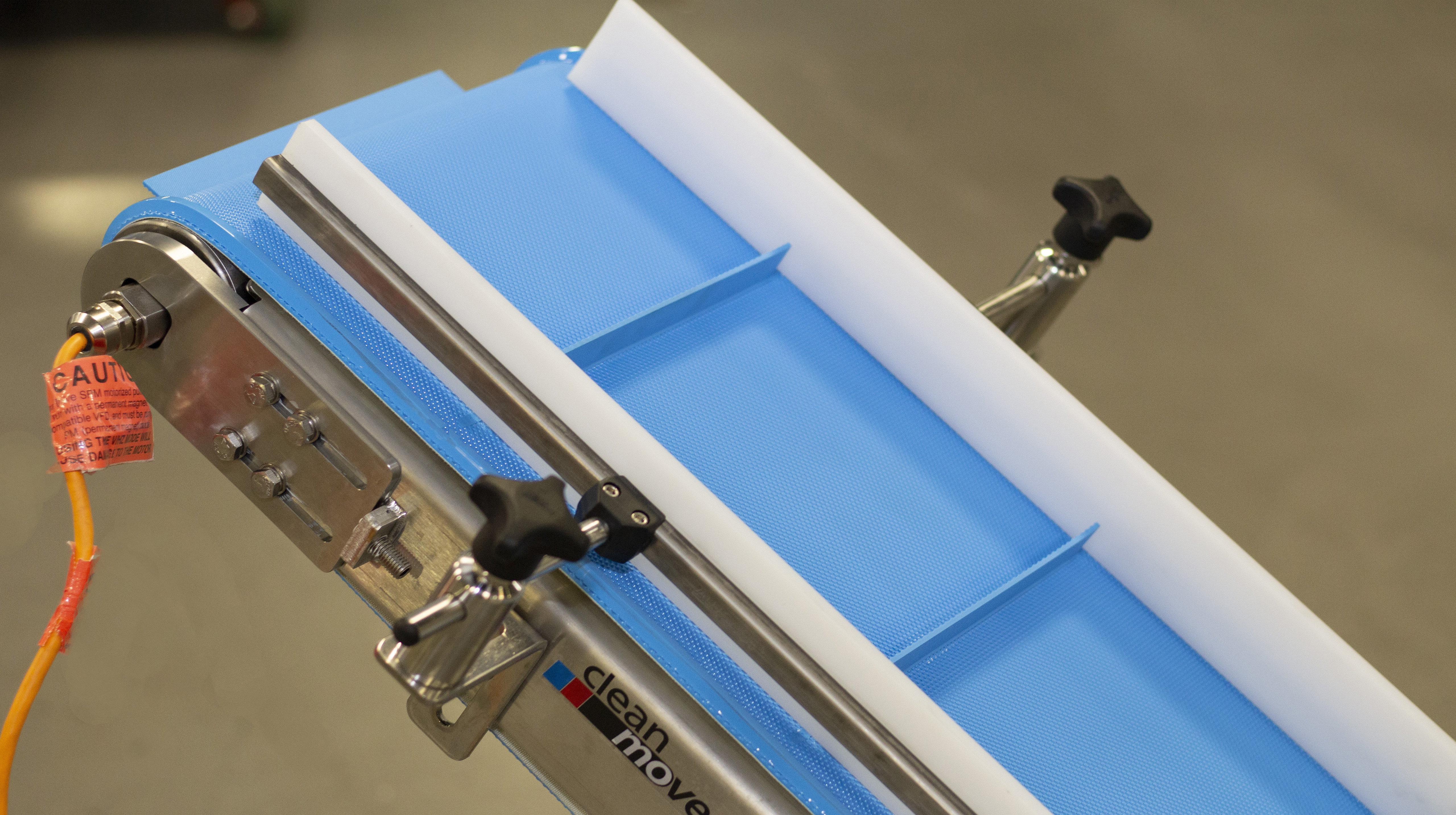

Now, belt and plastic modular-belt varieties of CleanMove Standard conveyors from mk North America are available with an inner drive. Conveyors with these drives can deliver speeds to 250 fpm and are suitable for horizontal, incline, and Z-shaped conveying applications.

Conveyor inner-drive features

The conveyor inner drive takes the form of an energy-efficient permanent-magnet drum motor. Because the motor is oil-free, it’s safe for inclusion on conveyors that transport food. The inner drive option makes for more compact conveyor designs than those based externally mounted motors. In addition, conveyors that include this drive technology are easier to clean due to the integrated motor format. All of these benefits ultimately lower per-conveyor operating costs.

For more information, visit mk North America at www.mkcleanmove.com.

Note that CleanMove stainless-steel conveyors excel in the pharmaceutical and food industries — with three platforms offering cleanability, performance, reliability:

CleanMove Standard conveyors for handling packaged food or pharmaceuticals in relatively dry environments

CleanMove Plus conveyors for processing bakery goods, snacks, and fruits and vegetables

CleanMove Ultra conveyors for caustic settings subject to high-pressure washdown — whether clean in place (CIP) or Clean Out of Place (COP). CleanMove Ultra conveyors are employed in facilities that process raw meats, poultry, fish, and dairy products.

Leave a Reply

You must be logged in to post a comment.