Gear quality standards developed and published by the American Gear Manufacturers Association (AGMA), have dominated gear manufacturing in the U.S. market since the 1960s. But in the 1990s, AGMA began working with the International Organization for Standardization (ISO) to update and harmonize gear quality standards, with several versions of both AGMA and ISO standards published from the mid-1990s until now. Here’s a brief recap of their evolution and the current status of both AGMA and ISO standards.

The American Gear Manufacturers Association (AGMA), is the body accredited by the American National Standards Institute (ANSI) to write all U.S. standards for gearing. The International Organization for Standardization (ISO) develops international standards based on input from the standards bodies in member countries, such as ANSI (U.S.), JISC (Japan), and DIN (Germany). Since 1993, AGMA has served as the Secretary for the ISO Technical Committee 60 (TC 60), which is responsible for developing international gearing standards.

Introduced in 1988, the AGMA standard ANSI/AGMA 2000-A88, Gear Classification and Inspection Handbook – Tolerances and Measuring Methods for Unassembled Spur and Helical Gears, was the dominant standard in the U.S. market for many years. In fact, this standard is still used or referenced by many manufacturers today.

The ANSI/AGMA 2000-A88 standard defined 13 quality classes, ranging from Q3 to Q15. In this standard, lower quality numbers indicated lower precision. In others words, the lowest quality gear would be designated as Q3 and the highest quality gear would be designated as Q15.

Cylindrical gears are those with teeth arranged on a cylindrical surface, with the teeth being either parallel or at an angle to the gear axis. The most common cylindrical gears are spur and helical types. Gear racks are also a type of cylindrical gear, but have an infinite pitch cylinder radius.

In 1995, ANSI/AGMA ISO 1328-1:1995 was published. This standard was jointly developed by ISO Technical Committee TC 60 with ANSI/AGMA participation, and was adopted by AGMA and approved by ANSI in 1999.

The 1328 standard introduced significant changes to measuring and classification methods, and provided 10 accuracy grades (notice the use of the word “accuracy” rather than “quality”), ranging from A2 to A11. In this standard, lower numbers indicated higher precision (smaller tolerances).

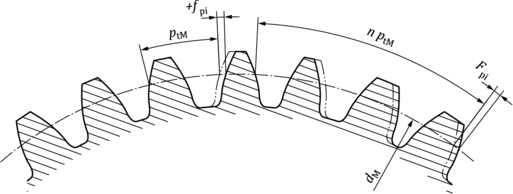

Image credit: ISO

In the early 2000s, both the ANSI/AGMA 2000-A88 and the ANSI/AGMA ISO 1328-1:1995 standards were replaced by ANSI AGMA 2015-1-A01, which combined the grading system of ISO 1328-1 with measurement and evaluation methods of ANSI/AGMA 2000-A88.

The new standard also added a new accuracy grade grouping system, which included low (A10 and A11), medium (A6 to A9), and high (A2 to A5) accuracy designations. Each accuracy grouping includes a specific set of measurement criteria which must be met. For low accuracy gears, only cumulative pitch and single pitch deviation are required, while medium accuracy gears require the same criteria as low accuracy gears, along with total profile and lead. High accuracy gears require the criteria of medium accuracy gears, in addition to slope and form.

In 2013, the most current quality standard for cylindrical gears, ISO 1328-1:2013 Cylindrical Gears — ISO System of Flank Tolerance Classification — Part 1: Definitions and Allowable Values of Deviations Relevant to Flanks of Gear Teeth, was introduced. This standard was developed by ISO Technical Committee 60 and approved by AGMA in 2014. The basis of ISO 1328-1:2013 was ANSI/AGMA 2015-1 A01, although this revision to 1328-1 includes significant technical updates to formulae and to methods for measurement and evaluation. ISO 1328-1:2013 is published by ANSI as ASNI/AGMA 1328-1-B14, and although the names are slightly different, the ISO and ANSI standards are identical.

Leave a Reply

You must be logged in to post a comment.