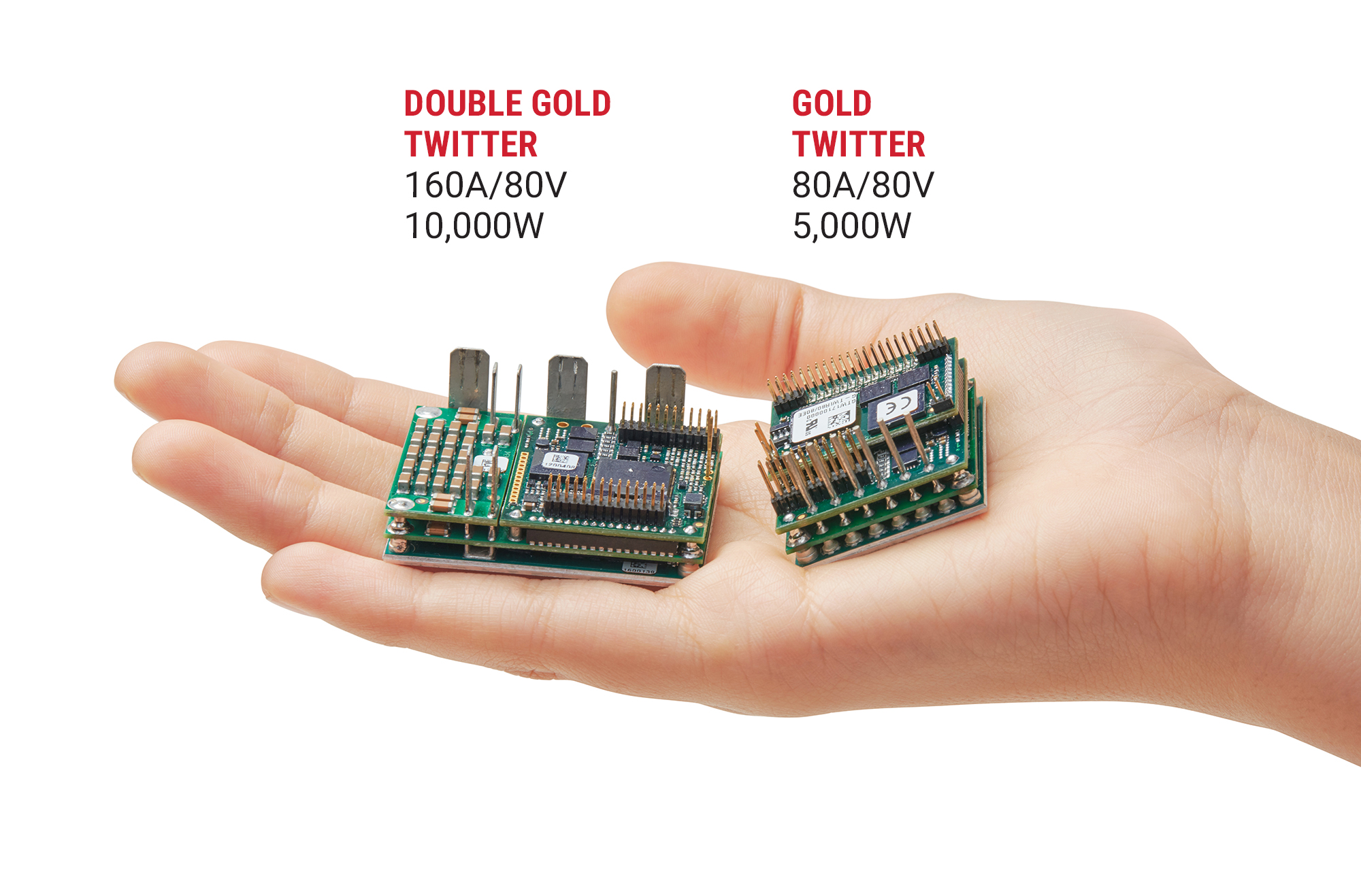

At IMTS 2018, Elmo Motion Control will showcase its new Double Gold Twitter ultra-small servo drive and its Platinum Maestro motion controller, which controls up to 256 axes. These motion products suit the most demanding applications in the era of Industry 4.0.

The new Double Gold Twitter is among the smallest STO-certified (IEC 61800-5-2, SIL-3) servo drives on the market. It delivers to 10,000 W and weighs only 1.2 oz — with continuous currents of 160 A (80 V) and 140 A (100 V).

This miniature drive can mounts on moving loads, on motors, or inside motors to help engineers save space, improve machine performance, reduce cabling, and eliminate electrical cabinets, all while delivering unprecedented power.

Visit Elmo Motion Control at IMTS 2018 (IAMD) in Chicago at Booth #134142 to see these and other innovative motion solutions and capabilities for efficient and cost-effective smart machines.

Also — learn how smart drives and controls can help improve machine performance while enabling manufactures to achieve more for less at an Elmo Motion Control presentation.

The Paradox of Smart Manufacturing — which won the 2018 first prize SPS Roberto Maietti Award (recognizing thought-leading abstracts) will be presented in a session — Challenges of automation: Efficiency and flexibility. Join Elmo product & sales enablement manager Tomer Goldenberg for this live presentation on Tuesday, September 11, 2018 at 3:15 pm (W196-A).

Also be sure to visit www.elmomc.com.

Leave a Reply

You must be logged in to post a comment.