HMI SCADA design has traditionally been a lengthy and error-prone task, while the result limited operator visibility to only what had been preprogrammed into the application. In today’s era of smart manufacturing, these problems can be solved. The latest version of FactoryTalk View software from Rockwell Automation improves the operator’s experience with valuable, data-driven information while also delivering improved design-time productivity via tighter integration with the control system.

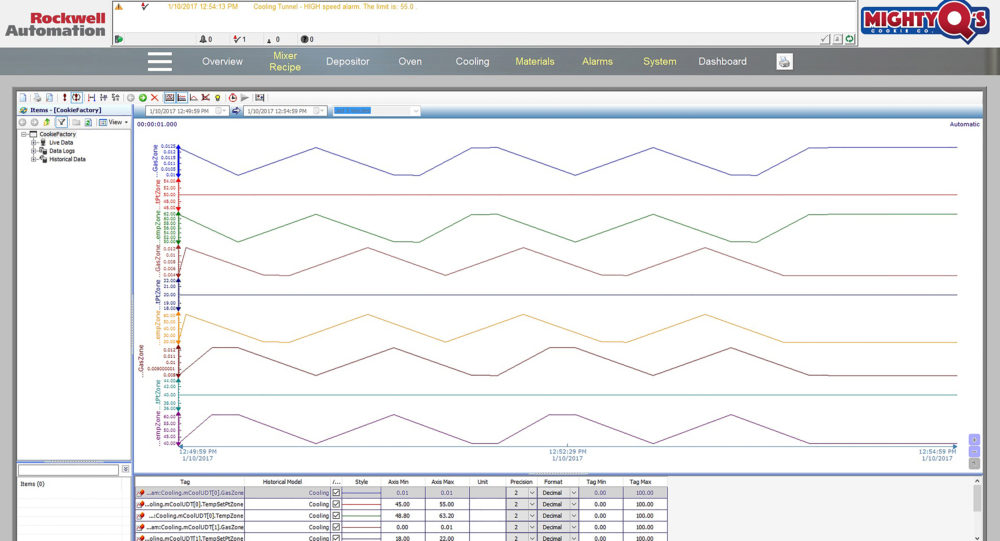

FactoryTalk View v9.0 software empowers operators to make quicker, better informed decisions with access to TrendPro, a new trending tool. TrendPro helps operators to access real-time data with built-in analysis tools. The tool showcases contextualized production data by pulling from a variety of sources that were once difficult to access: FactoryTalk View SE data logs, FactoryTalk Live Data and FactoryTalk Historian data. The latest release provides operators easy, ad-hoc, drag-and-drop capabilities that bring trends front and center.

“As part of the Rockwell Automation Integrated Architecture platform, our FactoryTalk View v9.0 software provides an improved user experience for HMI developers and operators,” said Chirayu Shah, product marketing manager, Rockwell Automation. “The new technology improves time to deployment, enhances visualization of real-time data, and streamlines mobile use.”

By taking advantage of the Integrated Architecture portfolio, FactoryTalk View v9.0 software builds on the ability to directly connect with Allen-Bradley ControlLogix tags. New tag-extended properties eliminate the need for redundant engineering work. Previously, developers could spend hours or days defining tags in their control system, only to turn around and replicate that process in their HMI. With new tag-extended properties, developers have direct access to tag descriptions, engineering units and min/max settings. This leaves less room for duplication errors and streamlines the design process.

Additionally, the new tag-extended properties enable simplified language switching. Instead of requiring a developer to program language strings within the HMI, translated content can now be directly accessed from the controller, further saving design time.

FactoryTalk View v9.0 software also introduces RecipePro+. This new recipe manager offers an easy way to download and upload multiple machine parameters at once. The RecipePro+ editor includes a user-friendly interface to create and edit recipe files, and allows for importing and exporting files. For Rockwell Software RSView 32 users looking to modernize their HMI SCADA, RecipePro+ will greatly streamline migration to FactoryTalk View SE software.

As part of a continued focus on the mobile workforce, FactoryTalk ViewPoint mobile HMI software offers yet another layer of improved productivity in version 9.0. Operators are now able to acknowledge or shelve an alarm notification directly from a mobile device. The alarm table is optimized for mobile devices and built into the framework with complete alarm details, as showcased in the live demo.

Leave a Reply

You must be logged in to post a comment.