MD&M West is known for its unwavering usefulness to attendees and exhibitors alike, and this year’s event delivered as usual. Here’s what we saw at the Bosch Rexroth booth (within the colocated ATX West) during our visit at the show.

MD&M West is known for its unwavering usefulness to attendees and exhibitors alike, and this year’s event delivered as usual. Here’s what we saw at the Bosch Rexroth booth (within the colocated ATX West) during our visit at the show.

A main focus at the Bosch Rexroth booth was connected automation technology — also called the Internet of Things, IIoT, and Industry 4.0 — depending on the context and who you ask. Showcasing Bosch Rexroth offerings here was an Open Core Engineering demonstration — in the form of spreadsheet-based networked control of a multi-axis Cartesian system. Read more about the related offering — Rexroth Open Mechatronics — and the demonstration at ATX West here. There’s an explanatory video at the link.

In short, Open Core Mechatronics is multi-axis motion control and programming that lets engineers access the core of Rexroth’s motion-logic drive and control platforms … so they can use familiar IT languages (MATLAB, LabVIEW and even Visual Basic for Applications or VBA and Java) to write automation functions and applications.

Related: Rexroth’s Open Core Interface lets machine builders create functions without a PLC

Software engineers can also streamline HMI programming through Rexroth’s Open Core Interface.

Leveraging predefined software functions, machine builders can create custom interfaces in the form of mobile apps or HMI screens — to let users perform machine functions and collect data from virtually anywhere.

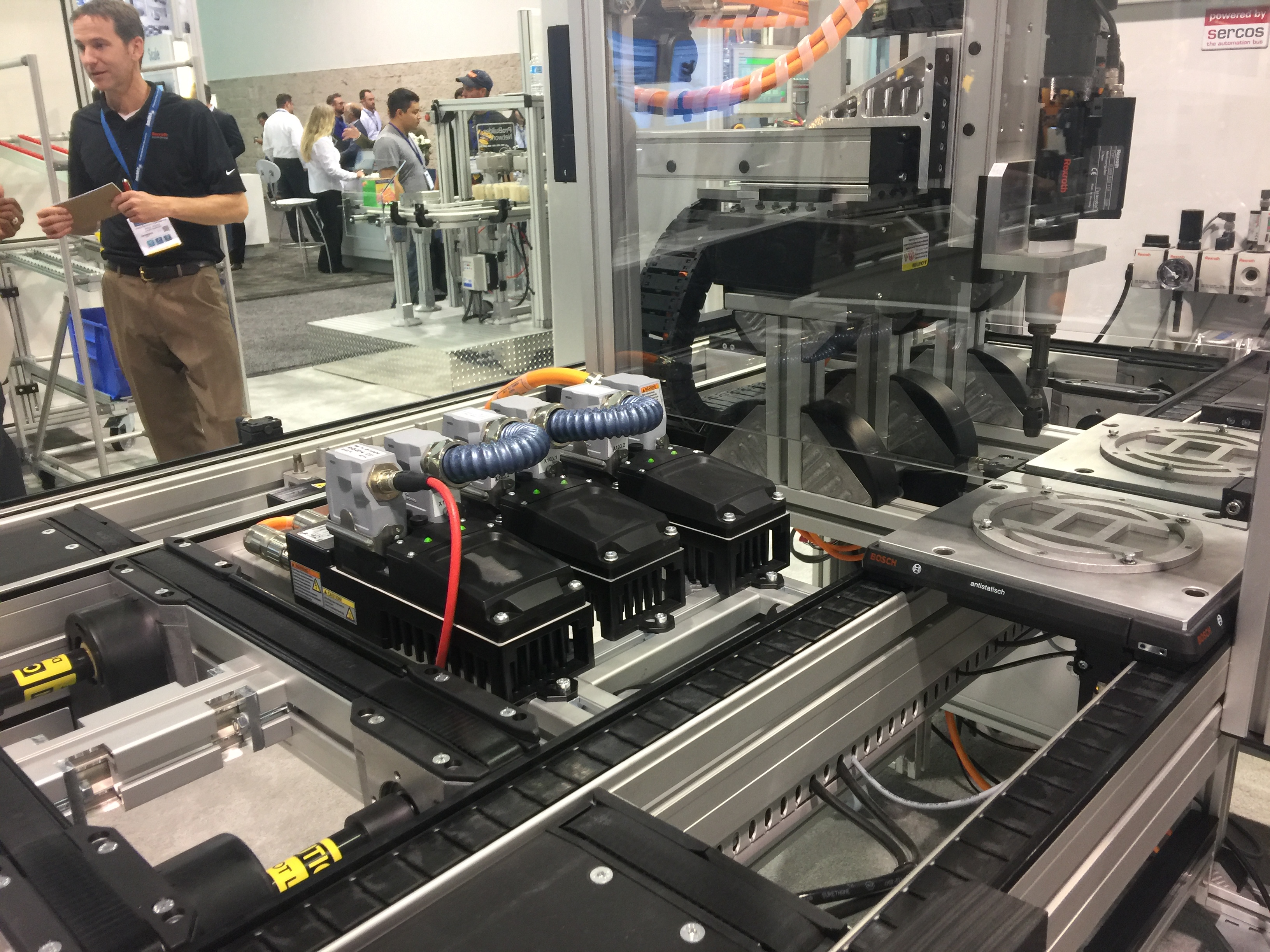

Other items Bosch Rexroth had on display at ATX West were their second-generation electromechanical cylinder with a hygienic design; details on their new microsite for resource kits; details on their Factory Automation Road Show traveling truck of technology; and their TSplus and VarioFlow plus conveyors:

Prototype in 2015 — and now the product is here to replace factory whiteboards

Bosch Rexroth also showed the new release of something I saw as a prototype with my colleague Mary Gannon back in 2015 — a digital iteration on the old-school whiteboard so common on factory floors for tracking production data.

Here’s a little tweet from that 2015 visit with Bosch Rexroth with Morrell Group graciously hosting … 3D-printing and other technologies were on display:

Precision #3Dprinting from #voxeljet at #RexrothI40 event at @morrellgroup | Prints of sand for direct #moldmaking pic.twitter.com/AW3Y2bjA6f

— Elisabeth Eitel (@EitelonDesign) September 15, 2015

Called the Manual Production Systems & Active Cockpit, this digital communication station lets workers and managers access production data.

Manual assembly will always be part of manufacturing. So to serve this portion of the factory floor in a modern way, Rexroth’s Active Cockpit connects to data-sensing manual and automated processes to give plant personnel a realtime view of production data, work instructions, meeting minutes — whatever information is needed for instant access to boost production.

Paring this technology with Rexroth’s Manual Production Systems (MPS) makes manual jobs even more efficient. (With Rexroth’s reconfigurable aluminum framing, MPS makes lean manufacturing easy and lets manufacturers adapt quickly to changing demands.) As literature we got on the product explains, Active Cockpit is an interactive web-based communications platform that detects all relevant data for a production line, updates it in a dynamic manner, and visualizes it clearly in realtime, directly on the line:

ActiveCockpit software from Bosch Rexroth delivers Industry 4.0 technology straight into users’ hands as it records, processes and visualizes manufacturing data in real time. So IT applications such as production planning, quality data management and e-mail dispatch connect with software functions from machines and systems. Key metrics clearly display in realtime in the most appropriate format — so on a large touchscreen directly at the manufacturing line or on an interactive tablet onsite, for example.

Personnel can immediately see production problems to initiate corrections based on all relevant data. For more information, visit boschrexroth.com/en/us/activecockpit.

Smattering of other items at the Bosch Rexroth booth

Below are details on a few other items Bosch Rexroth displayed at ATX West — enjoy. Also note that Bosch Rexroth will be showing at CONEXPO-CON/AGG 2017 in Las Vegas March 7 through 11. Catch them at IFPE – South Hall 3 – S80214 if you’re attending.

Right turn for higher energy efficiency: Frequency converters from Rexroth

VarioFlow plus expands application range for conveyors

Rexroth ball-screw assemblies increase service life by 80%

Leave a Reply

You must be logged in to post a comment.