MD&M West is in full swing in Anaheim, and new products for use in medical devices (or medical-device manufacture) abound here. This is some of what we saw at our second day at the show.

MD&M West is in full swing in Anaheim, and new products for use in medical devices (or medical-device manufacture) abound here. This is some of what we saw at our second day at the show.

Online configurability increasingly common from manufacturers

I started the morning at an informative session hosted by maxon precision motors and led by the company’s engineer Biren Patel — who we recently interviewed on a new controller offering. Read: Engineer Biren Patel exposes why the industry needs new positioning controllers for more on that.

Attendees learned how to choose a speed and torque controller for motor applications — and configure ESCON products. Patel also explained the workings of dc motors and relevant electrical principles to give attendees a bit of context.

maxon is also touting its maxon X drives tool at MD&M — an online offering that lets engineers configure and combine dc motors including DCX and DC-max motors, BLDC motors such as the ECX SPEED motor, GPX planetary gearheads, and ENX sensors to requirements.

Users can review detailed product and 3D data right away. Then maxon motor ships the final result to the engineer within 11 working days from Switzerland.

More specifically, maxon motor supplies high-precision dc brush and brushless motors and drives ranging from 4 to 90 mm — plus combines electric motors, gears, and dc motor controls into application-specific designs.

- Technology: Precision motion systems

- Manufacturer: maxon precision motors

- MD&M West 2017 Booth: 2282

The idea of online configurability (through either web-based tools or software with online-ordering functionality) is an offering that others at the show are touting, too. Manufacturer ProtoLabs — which has built much of their business on the efficient concept — is of course no exception.

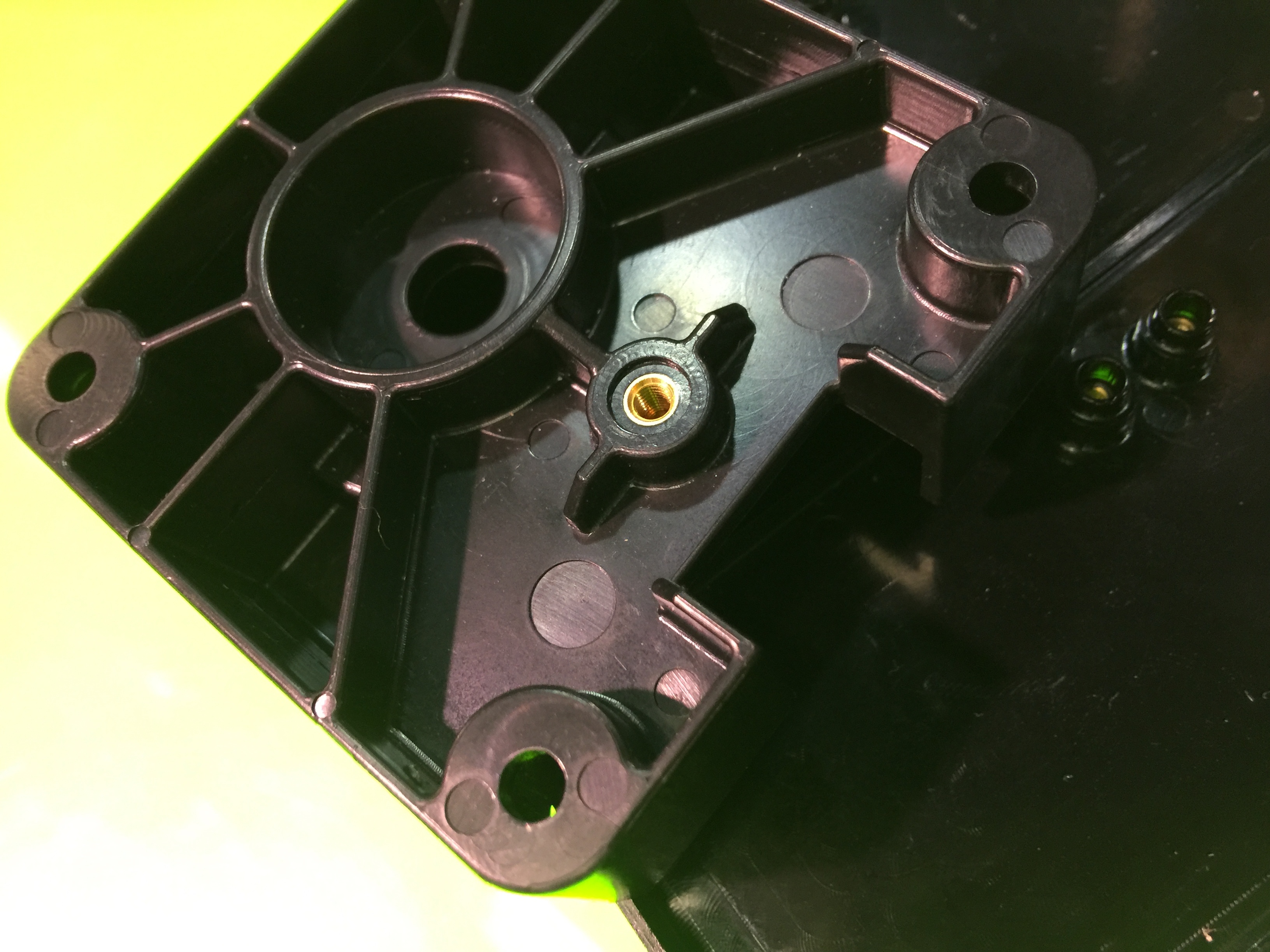

Announced at the MD&M and Pacific Design & Manufacturing show by ProtoLabs: Insert molding

Proto Labs — as published Design World sister site makepartsfast.com by my esteemed colleague Leslie Langnau — officially announced yesterday that it now offers an insert-molding service that expands on the company’s rapid-injection molding offerings. This new capability can produce 25 to 10,000-plus insert-molded parts in 15 days or less. I got the chance to chat with Becky Cater, product manager about the new offering:

#OnLocation #AdvMfgExpo #MDM2017 #MDMWest Booth 3415 @ProtoLabs https://t.co/4dGRt639ej

— Lisa Eitel (@DW_LisaEitel) February 8, 2017

Insert molding is the overmolding of plastic material around inserts to create a finished mixed-media part. Inserts are usually metal to reinforce the plastic’s mechanical properties.

Small motors and linear actuators abound

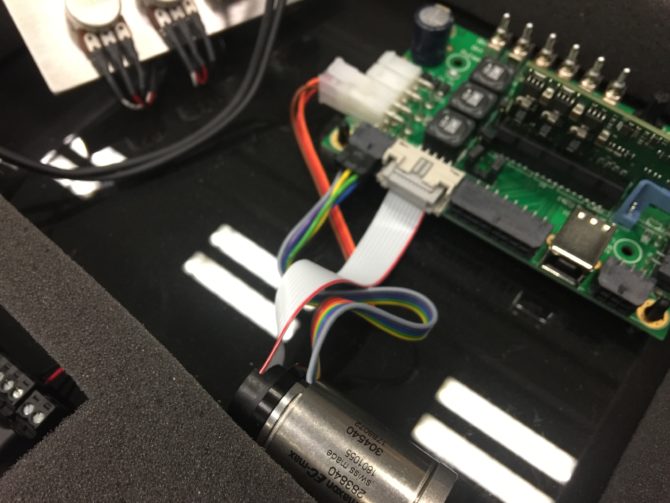

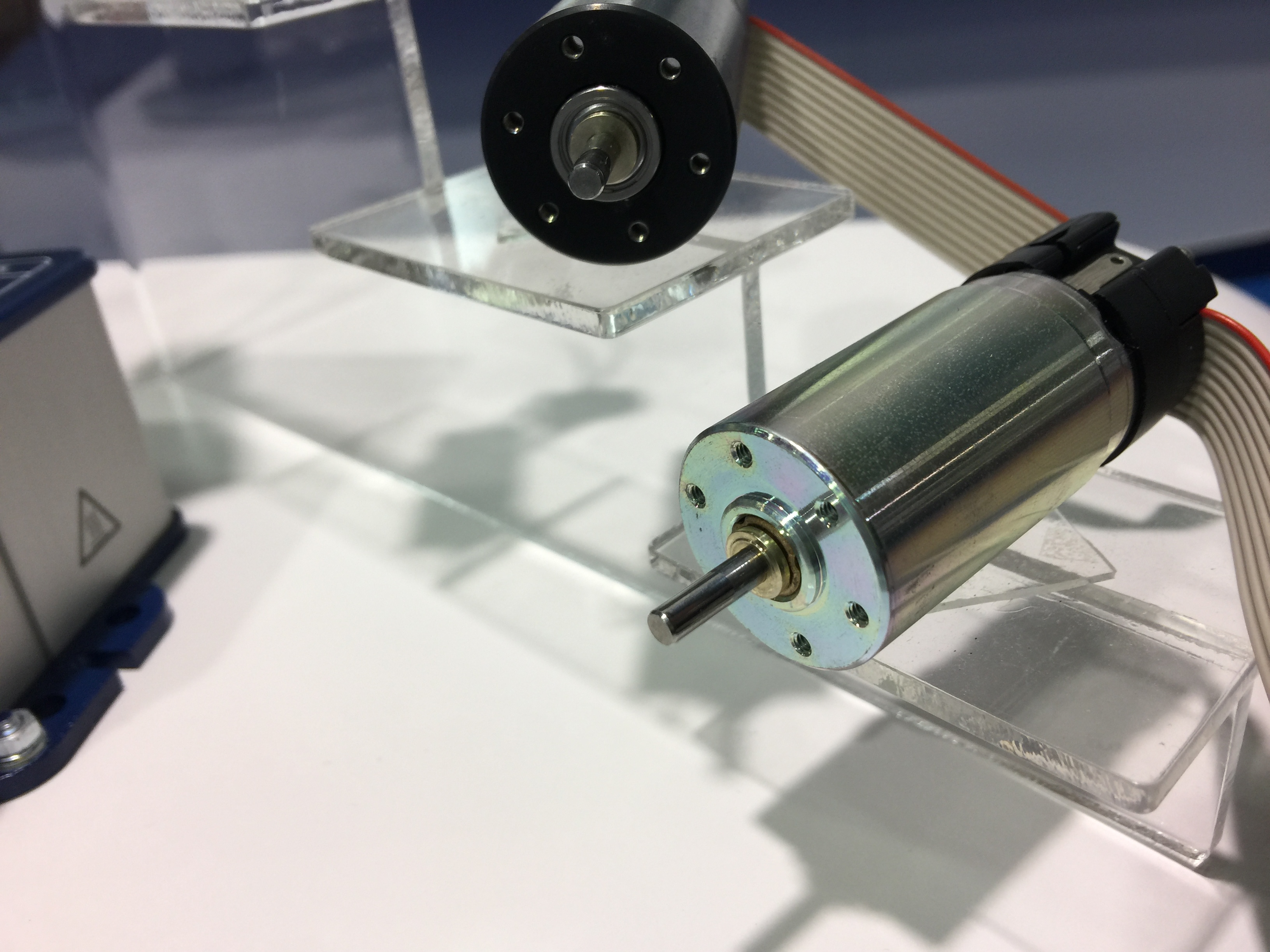

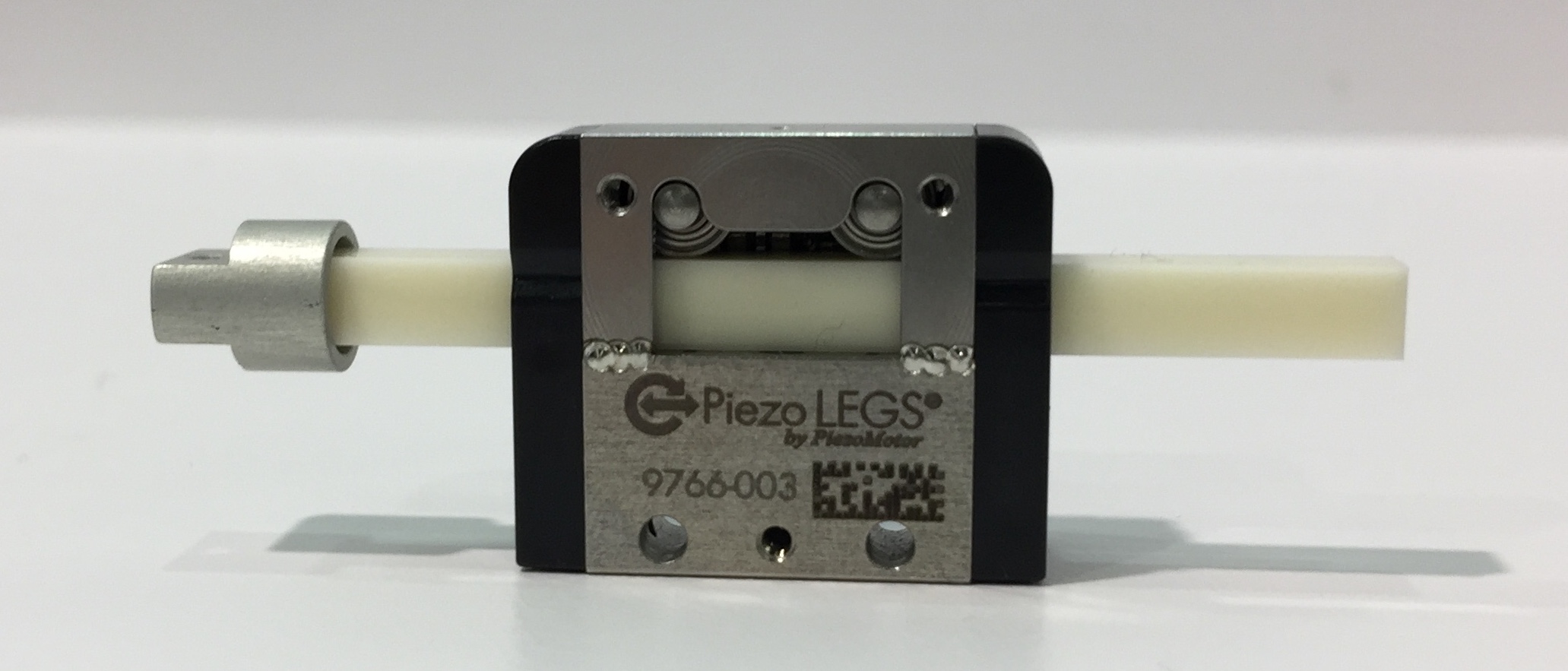

MICROMO is full-service manufacturer of micro-motion designs to boost performance with brushed and brushless standard and flat dc motors, stepper motors, piezoelectric motors, and linear motors that deliver higher efficiency and more compact designs than a lot of other offerings …

Here is one linear-motor stage setup they have at the show.

- Technology: Micro-motion designs

- Manufacturer: MICROMO

- MD&M West 2017 Booth: 4128

We also got notice today that MICROMO just announced a new piezo-based offering. This is an LL06 linear motor for OEM applications that need precise positioning. Speed ranges from nanometers to millimeters per second. Expect more from us on this soon.

Still more to see at other booths

At the US Digital booth, there are myriad encoders on display — including E4T and S4T miniature optical encoders in higher resolutions of 400 and 500 CPR. The real benefit of these encoders is that they use transmissive optical sensing technology …

… and the new resolutions are a 38% increase in available CPR. That lets the encoders give feedback to 2,000 pulses per revolution. Te take-home point is that the encoders have the same exact form factor and output-signal robustness as older versions.

E4T encoders from @usdigital excel in applications needing noise immunity #AdvMfgExpo @MDM_Events @WTWH_MEmich Click To TweetThe 400 and 500 CPR options retain the E4T’s simple and efficient, push-on hub disk assembly process …

… helping design engineers keep installation time, assembly cost and complexity to a minimum. Get sample and production quantities of the 400 and 500 CPR E4T from the manufacturer and visit then if you’re in Anaheim …

- Technology: Miniature optical encoders

- Manufacturer: US Digital

- MD&M West 2017 Booth: 4128

Offerings from IKO expands linear bearing lineup

At a quick visit to IKO International, we learned the manufacturer has expanded the number of carriage sizes and options on its miniature bearings. Sizes are as small as 1 mm.

The supplier also sells standard and wide-rail versions of its C-Lube Linear Way ML linear bearing for use as single-row track rail. ML standard models span a range of 1 to 25 mm wide track rails, with wide-track rail models to 42 mm. Read more about this on our Design World sister site — bearingtips.com — IKO miniature bearings in more size and carriage options.

- Technology: Roller bearings and linear bearings

- Manufacturer: IKO

- MD&M West 2017 Booth: 4533

Here’s another item IKO is showing at its booth — a nano linear table:

Tomorrow: More to see at MD&M … with IIoT

Alas, it never seems as though there’s enough time to see all of MD&M West. But one talk that I’ll be stopping to see tomorrow is that by Dan Yarmoluk, IoT Business Development Executive and business and market development lead for ATEK IoT products. (He’s been involved in analytics, embedded design and components of mobile products for more than a decade.) Yarmoluk will be speaking at Intelligent Maintenance: Mapping the IIoT Process (February 9th from 2:05 to 2:40) and afterwards on a panel discussion — Tips for Attracting and Maintaining a Multi-Generational Workforce and Overcoming the Skills Gap (on February 9th from 2:40 to 3:30). Tweet at me if you plan on going.

See you at the @ATEKAccess Dan Yarmoluk talk @DW_LisaEitel — #MDM2017 #AdvMfgExpo Click To Tweet

Leave a Reply

You must be logged in to post a comment.