At every MD&M event, manufacturers from around the globe announce new products for use in medical devices — or to take them from concept to market. This is what I saw at the first day of this year’s show.

At every MD&M event, manufacturers from around the globe announce new products for use in medical devices — or to take them from concept to market. This is what I saw at the first day of this year’s show.

First stop: Model Solution at Booth 873 (downstairs at MD&M)

The first meet of the day took us to Model Solution — a company that specializes in comprehensive prototyping, rapid design, tooling, and low-volume manufacturing. Expect us to cover this design house more in coming months on sister Design World website makepartsfast.com. At the booth we got to see examples of custom prototypes made with additive and subtractive processes.

Senior V.P. SS Park and Karl von Gunten took some time to detail items Model Solution helped design and make — precision-machined medical suction injectors; a women’s lacrosse helmet featuring several different materials; a working laptop prototype with popup keyboard; and tooling for injection-molding applications.

- Technology: Prototyping, rapid design, tooling, and low-volume manufacturing

- Manufacturer: Model Solution

- MD&M West 2017 Booth: 873

Explanation of Lin Engineering’s PT 104 linear actuator from Bryan Rodriguez

Applications engineer Bryan Rodriguez at the Lin Engineering booth is very keen on getting people excited about the manufacturer’s new PT 104 linear actuator (based on a hybrid stepper motor) that delivers more torque than competitive products. It supplies twice the torque of traditional NEMA-6 offerings. Essentially the motor makes fewer steps per revolution … that number of steps allows for better efficiency too.

- Technology: High-torque miniature linear actuator

- Manufacturer: Line Engineering

- MD&M West 2017 Booth: 3889

Universal Robots showing cobots that enable automation

Three collaborative robots from Universal Robots are at MD&M — demonstrating preprogrammed cycles that facilitate CNC machine tending and polishing, pick-and-place wire cutting, and injection molding. As in real installations, the cobots are running in high-traffic areas with no safety guarding.

At Universal Robots’ booth, a UR robot arm runs on a FESTO seventh-axis linear actuator performing machine tending alongside a glue dispensing application from UR Preferred Systems Integrator SP Manufacturing Solutions.

- Technology: Collaborative robots (cobots) and software

- Manufacturer: Universal Robots

- MD&M West 2017 Booth: 3889

Booth 4121 of UR robot distributor in Southern California, Numatic Engineering, is a testament to the flexible use of the cobots; Numatic will showcase a UR5 robot in a conveyor tracking application performing pick and place, a UR3 on a 7th axis ROLLON actuator and a UR5 robot in free motion for customer interaction. The booth is co-located with manufacturer of grippers and end of arm tooling, Zimmer Group, with a product segment geared toward being directly adaptable with UR robots.

“We see a collaborative robot as a tool on demand as needed – one that can quickly be transitioned between a wide variety of automated tasks. Flexibility in manufacturing involves ability to deal with variation in volumes, design and material handling as well as variations in the process sequences. We look forward to showcasing these important capabilities at the show,” says Universal Robots Area Sales Manager Craig Tomita.

A UR robot is also at the integrator Robatech West Booth 5066 … in a robotic gluing application using the UR5 robot integrated with the Robatech Gluing System.

“One of the main advantages in using UR in our booth, is also one of the reasons that the UR is so popular with your customers; no guarding required, “ says Costas Charalambous, Regional Sales Manager with Zimmer Group. “We also love the ease of programming and quick startup of the robot. We can quickly attach one of our manual tool changers to the robot without any additional adapter plates and then quickly swap between one of our pneumatic or electric grippers, to vacuum cups to our collaborative gripper.”

Rotary tables and more at the WEISS — Booth 4015

Weiss North America Inc. makes servo, cam, and linear motor-driven systems that take the form of rotary indexing tables, pick-and-place units, and other machines. The systems range widely in size and payload capacity — with the largest able to rotate 100 tons and the smallest able to accurately pick and place delicate one-ounce components. WEISS has U.S. headquarters in Ohio just outside of Cleveland, and offers their design and engineering support and services (as well as distribution and customization of indexing and positioning tables) thorugh that location. There’s a video from a previous MD&M West after the jump of Josh Treter of WEISS explaining a little about the company’s direct-drive products.

- Technology: Rotary index tables

- Manufacturer: Weiss North America Inc.

- MD&M West 2017 Booth: 4015

High-resolution optical encoders at Booth 4128

At the US Digital booth, there are myriad encoders on display — including E4T and S4T miniature optical encoders in higher resolutions of 400 and 500 CPR. The real benefit of these encoders is that they use transmissive optical sensing technology …

… and the new resolutions are a 38% increase in available CPR. That lets the encoders give feedback to 2,000 pulses per revolution. Te take-home point is that the encoders have the same exact form factor and output-signal robustness as older versions.

E4T encoders from @usdigital excel in applications needing noise immunity #AdvMfgExpo @WTWH_MEmich Click To TweetThe 400 and 500 CPR options retain the E4T’s simple and efficient, push-on hub disk assembly process …

… helping design engineers keep installation time, assembly cost and complexity to a minimum. Get sample and production quantities of the 400 and 500 CPR E4T from the manufacturer and visit then if you’re in Anaheim …

… helping design engineers keep installation time, assembly cost and complexity to a minimum. Get sample and production quantities of the 400 and 500 CPR E4T from the manufacturer and visit then if you’re in Anaheim …

- Technology: Miniature optical encoders

- Manufacturer: US Digital

- MD&M West 2017 Booth: 4128

SL Power Electronics power supplies also showing

SL Power Electronics is showing a suite of internal and external AC/DC power solutions for medical equipment … and representatives at the booth are touting medical trends that rely on the efficiency of such devices. In short, their MU425 family excels in home-healthcare therapeutic devices and imaging equipment (with up to 90% efficiency).

- Technology: Miniature optical encoders

- Manufacturer: SL Power Electronics

- MD&M West 2017 Booth: 1183

The ME Series is an external power supply for patient-monitoring equipment and respiratory devices needing electromagnetic compatibility. MB65 Series supplies offer 65-W convection-cooled operation. More after the jump.

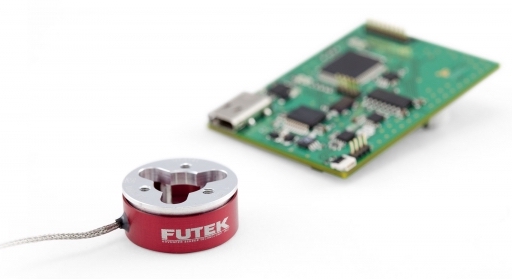

Torque sensors also on display — from FUTEK at Booth 1897

FUTEK Advanced Sensor Technology is using their booth space to show their QTA141 micro-reaction torque sensor … a design doing nothing less than imparting the sense of touch to robotic surgical platforms.

Torque applied through the sensor induces elastic deformation in strain gauges to prompt measurable change in voltage output from a four-wire analog interface. The strain-gauge arrangement lets the sensor measure clockwise and counterclockwise torque directions … with torque feedback versus current loop technology improved at least tenfold over previous designs.

Torque applied through the sensor induces elastic deformation in strain gauges to prompt measurable change in voltage output from a four-wire analog interface. The strain-gauge arrangement lets the sensor measure clockwise and counterclockwise torque directions … with torque feedback versus current loop technology improved at least tenfold over previous designs.

- Technology: QTA141 micro-reaction torque sensor

- Manufacturer: FUTEK Advanced Sensor Technology

- MD&M West 2017 Booth: 1897

HIWIN at Booth 4411 — Known for linear motion, but showing much more

HIWIN is showing a lot at this year’s MD&M West, but they’re leading with their big North American debut of the RA605 6-Axis Robot.

The RA605 is a compact six-axis articulated robot that installs on floors, walls, and ceilings to execute workpiece manipulation, assembly, and complex machining tasks. The robot includes a controller and teaching pendant. Additional accessories available include electric grippers, end effector and base stand. Applications abound for assembly, deburring, pick-and-place, handling, grinding and polishing.

- Technology: Six-axis robot that installs on walls, ceilings, or tracks

- Manufacturer: HIWIN

- MD&M West 2017 Booth: 4411

Tomorrow: Cocktail reception with the Plastics Industry Association

Note that if it’s relevant to you, the Plastics Industry Association (formerly SPI: The Plastics Industry Association) is hosting a cocktail reception on Wednesday, February 8 at 5:00 p.m. PT in 204A. The organization’s President and CEO Bill Carteaux will speak on the power of plastics.

Plastics Industry Association @PLASTICS_US at #MSD2017 #AdvMfgExpo reception http://www.plasticsindustry.org/event/plastics-plastec-west Click To TweetAlso tomorrow: Early-morning technical session with maxon motor

By the way, if you’re around MD&M West in the morning tomorrow and pursuing technical tracks related to motors, keep an eye out for me and my esteemed colleague Courtney Seel. We’re attending a free maxon motor seminar hosted by maxon precision motors from 8:00 AM to noon in Anaheim Convention Center Room 201C. The manufacturer says that attending this course will help engineers learn how to choose a speed and torque controller for motor applications. Attendees will also learn how to configure ESCON products. Though basic motion knowledge is assumed, the instructor will explain the workings of dc motors and relevant electrical principles. Connect with them on Twitter for more information.

More 411 @maxonmotorusa on controller seminar using #ESCON + #EPOS at #MDMWest? Click To Tweet

Leave a Reply

You must be logged in to post a comment.