Gearmotors can incorporate different gear types. Common types include spur gears, worm gears, helical gears, planetary gears, even harmonic gears. One of the more common types, especially used with dc motors, is the planetary gearmotor.

The two biggest advantages of planetary gearmotors are high power density and compactness in both size and weight. Planetary gearmotor efficiency is usually fairly high as well, and they are usually highly accurate, more so than other gearing types, with virtually no backlash.

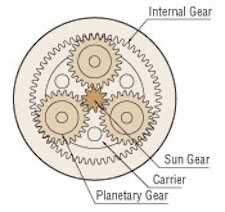

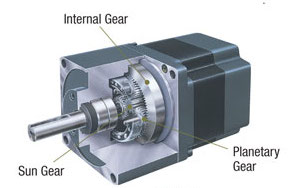

On the other hand, planetary gearmotors also tend to cost a little more than other types of configurations. This is due largely to their more complex design. Planetary gear system construction involves a central sun gear on the central axis surrounded by gears that mesh with the central sun gear, all of which is enclosed within a larger internal tooth gear. Because of the way they’re designed they can handle higher load requirements due to the load being distributed among several gears, from the central sun gear to the surrounding gears.

In contrast with a spur gear for instance, where torque is limited by the strength of each individual gear as they mesh one to one, a planetary gear system can handle more torque because torque is more evenly distributed via dispersion among the several planetary gears. This makes planetary gearmotors well suited for applications requiring higher torque.

Leave a Reply

You must be logged in to post a comment.