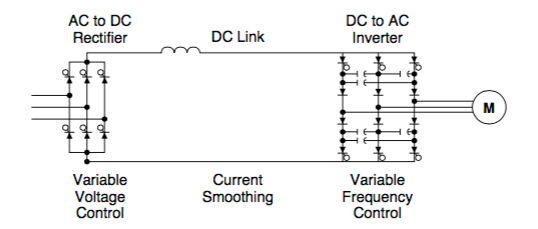

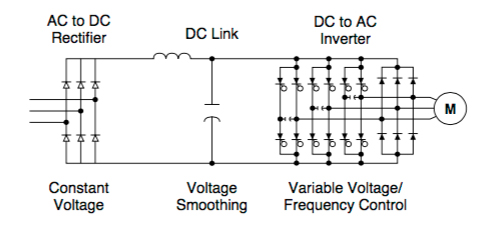

As we’ve discussed before, the main components of a variable frequency drive (VFD) are a rectifier (also referred to as a converter), which converts AC voltage to DC voltage, a DC bus (also referred to as a DC link), which filters and stores the DC power, and an inverter, which converts the DC power back to AC power with the required frequency and voltage.

While the basic hardware is the same in all VFDs, the inverter section of the drive can be one of several designs, depending on the application requirements. The two most common types of inverters are the current source inverter (CSI) and the voltage source inverter (VSI). As their names imply, current source inverters are fed with constant current, while voltage source inverters are fed with constant voltage. Consequently, the output of a CSI drive is adjustable, three-phase AC current, while a VSI drive produces three-phase AC voltage with adjustable magnitude and frequency.

Topology differences

A key difference between CSI drives and VSI drives is their energy storage method. CSI drives use inductive energy storage—that is, they use inductors in their DC link to store DC energy and regulate current ripple between the converter and the inverter. Conversely, VSI drives use capacitive storage, with capacitors in their DC link, which both stores and smooths the DC voltage for the inverter. This difference in storage method has a noticeable effect on drive performance, as we’ll discuss later.

Image credit: Ontario Hydro

The types of power switching devices used are another distinction between the two drive types. Modern CSI drives typically use gate turn-off thyristors (GTOs) or symmetrical gate commutated thyristors (SGCTs), which are semiconductor switches that are turned on and off, creating a pulse width modulated (PWM) output with regulated frequency. VSI drives commonly use insulated gate bipolar transistors (IGBTs), which create a PWM voltage output with regulated frequency and voltage.

Performance differences

The output current of a CSI drive contains high harmonics, which necessitates that CSI drives include filters on the input and output sides. Because of the additional components, CSI drives are typically non-integrated, meaning that the transformer (required in high-horsepower applications) and harmonic filters are separate from the drive. VSI drives, with fewer components, are often supplied as integrated designs, with smaller footprints than non-integrated, CSI designs. The use of fewer components also gives VSI drives a better mean time between failure (MTBF) rate in many cases.

VSI drives are typically more efficient than CSI designs. This is because the IGBT switching devices used in VSI drives are inherently more efficient than the GTO or SGCT devices used in CSI versions. Both types of drives, CSI and VSI, are capable of returning regenerative energy from the load to the line, but CSI drives are also capable of returning energy to the supply. In order for VSI drives to do this, they require an additional converter.

With CSI drives, the load (motor) parameters are an integral part of the control system, so the motor must be matched to the drive, which precludes the use of one drive for controlling multiple motors.

Primary applications for CSI drives are those that require torque control (which is achieved by controlling current). They also typically have higher horsepower ratings than VSI designs. VSI drives, on the other hand, are well-suited for highly dynamic applications, with fast changes in motor speed or torque, thanks to the fast switching times of IGBT devices.

Leave a Reply

You must be logged in to post a comment.