Image credit: Encoder Products Company

Electrical noise is a common problem that occurs during the transmission of an incremental encoder’s signal to the receiving electronics, especially when the cable lengths are very long. Stray electromagnetic fields or currents induce unwanted voltages into the signal. These voltages can cause the receiver to make false counts, producing errors in the position or velocity feedback.

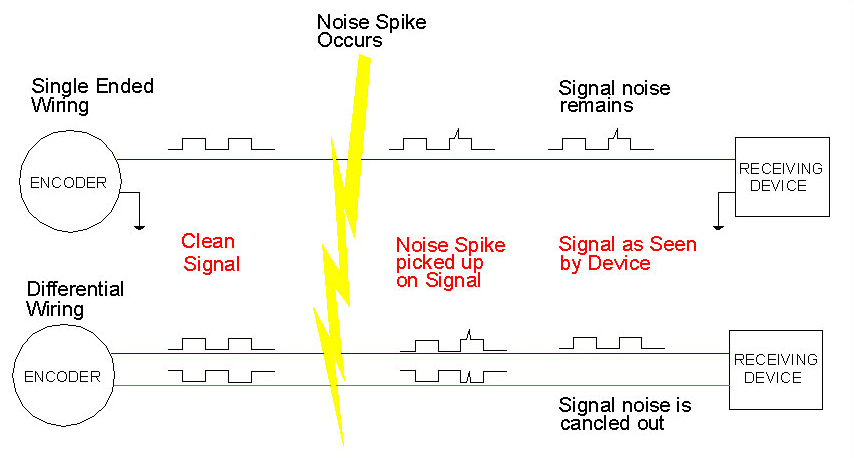

The primary way to alleviate electrical encoder noise is to use TTL output – also known as differential line driver output. This output format provides not only the standard A and B square wave signals and a Z reference signal, it also includes their complementary signals, /A, /B, /Z (sometimes written as A’, B’, and Z’). These complementary signals are produced by splitting the output of each channel (A, B, and Z) into two signals that are 180 degrees out of phase (complements) with each other. In other words, when the A signal is high (logic state 1) the A’ signal will be low (logic state 0). The receiving electronics take the state of that channel as the difference between the two signals

In order for the complementary signals to be read, however, the receiving electronics must have a circuit that is designed for differential input – known as line receiver input. In addition, the wires for each channel (A and A’, for example) should be a twisted pair. In this twisted pair of wires, any electrical encoder noise that is induced will be the same on each signal. The receiving electronics recognize only the difference between the two signals, and because the signals are complements (equal in magnitude, with 180 degree phase lag) but the noise is common mode (equal on each signal, with no phase lag), the noise is cancelled out on the receiving end.

Image credit: Quantum Devices Inc.

Q: What is differential line driver output?

A: Line driver is an output method that uses an integrated circuit designed for data transmission at high speeds over long distances and complies with the RS-422 standard. The term “differential” refers to the fact that this output method uses two complementary signals on each channel.

Leave a Reply

You must be logged in to post a comment.