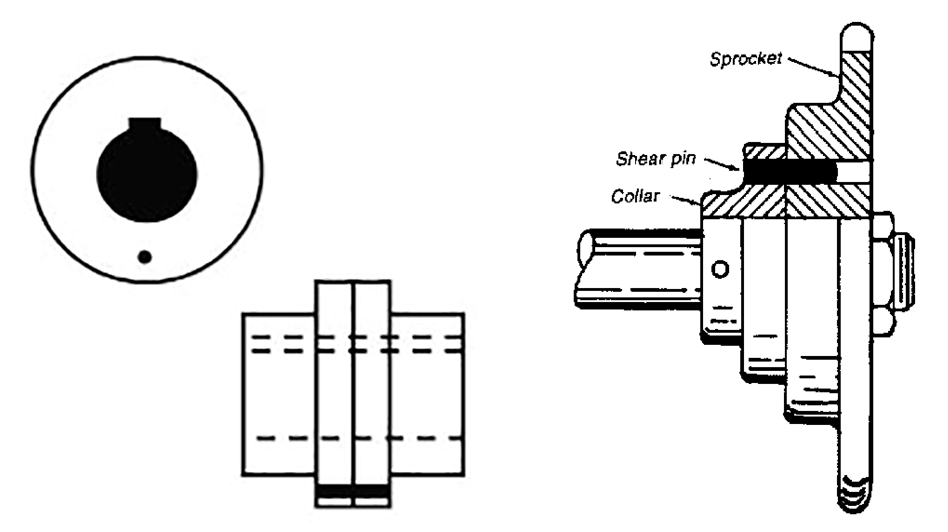

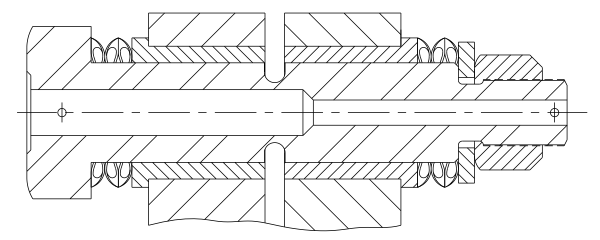

Shear pin torque limiters are a simple, cost-effective design for protecting equipment from torque overloads. In their most basic form, they incorporate a pin (or, for very high torque ratings, multiple pins) inserted between two rotating elements, such as discs or flanges.

Images credit: R+W America and M. Masaeli

When torque is being transmitted from the driving to the driven load, the pin experiences a shear force. If the transmitted torque causes a force that exceeds the pin’s shear strength, the pin breaks and the driving and driven loads are immediately de-coupled. This immediate de-coupling of the load makes the shear pin design a type of “disconnect” torque limiter.

Shear pin torque limiters are often compared to fuses because they’re designed to break and be replaced — rather than simply disengage and reset — after being tripped.

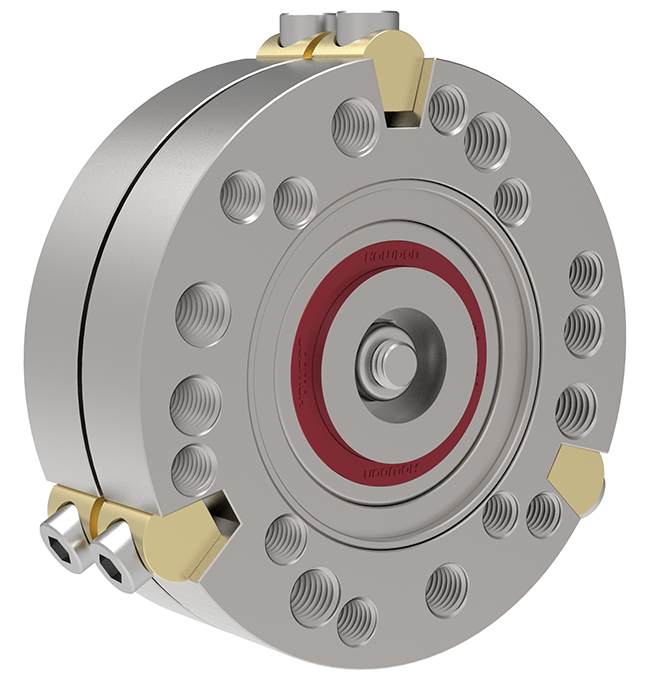

One drawback of shear pin torque limiters is that because the shear pin is sacrificed, it must be replaced, meaning downtime and labor costs are incurred before a restart is possible. Another drawback is the difficulty in predicting or setting the torque load at which the shear pin will break. The accuracy of a shear pin design’s rated torque, for example, is typically in the range of ±20 percent, while the rated torque accuracy of a ball detent torque limiter is in the range of ±5 percent. And even small stresses that occur during normal operation can weaken the shear pin over time and reduce the amount of torque required before the pin will break. To combat these issues, some manufacturers use specially-designed hollow shear pins.

Image credit: Kop-Flex

Another variation on the basic shear pin design uses wedge-shaped shear pins. (This design is branded as the “Wedgegard shear pin torque limiter” by the Howdon company.) Like traditional shear pin designs, the wedge pins are designed to break at a specific torque, but the accuracy of breaking torque is typically better than ±10 percent — a significant improvement over the accuracy of traditional shear pins. The wedgepins are also much easier to replace than traditional shear pins, reducing downtime and labor for resetting the torque limiter once it has tripped.

Image credit: Howdon

Shear pin torque limiters are a simple and cost-effective solution in heavy industrial applications such as mining equipment, rotating equipment in paper mills, pumps for water treatment, and large conveying systems. However, because of their low breaking torque accuracy, shear pin designs are rarely found on servo-driven systems, which commonly use ball detent, magnetic, or friction-based torque limiters. And for applications that can see extremely high torque (and horsepower) conditions — several kNm and above — hydraulic torque limiters are sometimes chosen over shear pin designs.

Leave a Reply

You must be logged in to post a comment.