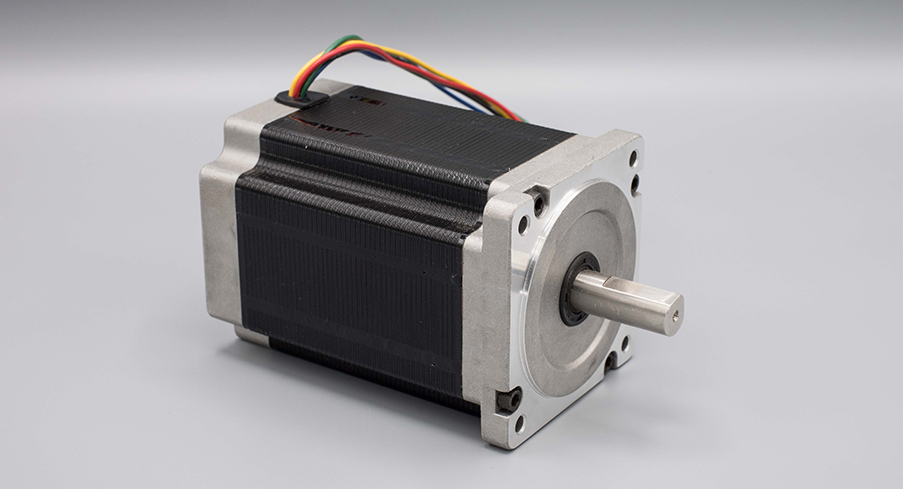

ISL Products Intl. Ltd., leader in value-added manufacturing and engineering services for electronic/electromechanical components, now sells value-added hybrid, permanent magnet (PM) and variable-reluctance stepper motors which meet the exact positioning, holding torque, and repeatability specifications of the broadest array of automation designs. As stepper motors employ the theory of operation for magnets to make the motor shaft turn a precise distance when a pulse of electricity is supplied, they are appropriate in a broad range of high-precision motion control designs. ISL’s brushless stepper motors provide either rotary or linear motion and are controlled by an open-loop system (non-feedback system) to facilitate robust, economical, repeatable, and low-maintenance operation.

ISL’s stepper motors are delivered in frame sizes ranging from NEMA 8 to NEMA 52 (20 mm – 130 mm) and feature a 1.8° (two-phase) step angle. Additionally, 0.9° (two-phase) and 1.2° (three-phase) step angle configurations are available. To ensure OEM’s unique requirements are met, ISL engineers help identify the optimal stepper motor solutions for each application. Included among ISL’s stepper motor customization capabilities are those pertaining to brake, gearhead, torque density, voltage, output speed, encoder/driver, power, current, lead screw/ball screw (linear stepper), all-in-one driver/controller, step angle, phase and pole count, lead wire/connector, shaft configuration and material.

These customizable, value-added stepper motors are commonly used in industrial automation, retail and vending machines, robotics, dispensing machines, 3D printers, machine tools, manufacturing equipment, conveyor and fluid control systems, automated guided vehicles (AGV), packaging, and food processing equipment. They are also specified for ticketing, gambling, labelling, textile, and carving machinery, as well as CNC (Computer Numeric Control) machines and medical devices.

Pricing for ISL’s value-added hybrid, permanent magnetic (PM) and variable reluctance stepper motors is determined based on customer specifications. Samples are available upon request. For more information, visit islproducts.com.

ISL Products Limited offers a comprehensive portfolio of supply chain and logistics management services. For more than 40 years, design engineers and OEMs have relied on ISL’s world-wide engineering sales and support network to deliver innovative and cost-effective solutions to help accelerate time-to-market. Products include audio components, motor and mechanical components, ballasts and power supplies, potentiometers-transformers, cable assemblies, and connectors. The company maintains a network of US sales representatives and is headquartered in Syosset, N.Y.

Leave a Reply

You must be logged in to post a comment.