Smalley now offers a new nested Spirawave wave spring series. Smalley has been producing nested wave springs as customs for over 30 years, but this will mark the first standard series on the market.

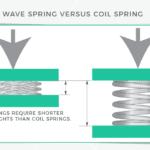

These multiple turn, flat wire wave springs are coiled in parallel to produce two to three times as much force as traditional single-turn wave springs. Nested Spirawave springs can be used to replace stacks of single-turn springs, eliminating misalignment and inconsistent loading.

The sturdy, tangle-resistant design allows for simple, time saving automated handling. Reduced costs can be realized from the use of a single spring and a simplified assembly process.

“Introducing a standard line of nested springs gives customers the ability to streamline production while meeting their high force requirements,” says Dan Frank, Research and Development Engineer.

Standard Nested Spirawave springs are available from 0.500 to 4 in. or 16 to 3,000 mm in carbon and stainless steel. Stock parts are available for overnight shipping.

Nested Spirawave springs are specified for many applications including heavy duty bearing preload, connectors, valves, and seals. The increased forces produced make them suitable for industries that need precision wave springs with high loads.

If a standard nested spring doesn’t meet the application requirements, Smalley has a team of experienced engineers capable of designing a custom nested spring. Custom or standard, Smalley will get the right part, in the right material, with No Tooling Charges.

Request a copy of the brochure or a free Nested Spirawave Wave Spring sample at nestedsprings.com.

For more than 50 years, Smalley has been the leading manufacturer of retaining rings and wave springs for OEM engineers worldwide. As an ISO 9001 and ISO 14001 company, we deliver quality products certified to: IATF 16949, AS9100 and ISO 13485. Custom or standard, we are dedicated to delivering the right part, in the right material for application. For manufacturing news and product updates, visit smalley.com/blog.

Leave a Reply

You must be logged in to post a comment.