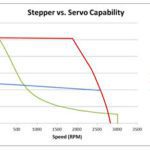

Applied Motion Products expands its family of STR Stepper Drives with two new ac-powered units for use in industrial applications powered by ac supply voltages. Offering the benefits of low noise, smooth motion, and high torque over wide speed ranges, the STRAC Stepper Drives bring high-performance motion control to basic step and direction applications. Units are ideal for larger motors and applications requiring maximum power.

Like their dc-powered counterparts, STRAC Stepper Drives feature advanced microstepping performance and current control with anti-resonance that improves motor smoothness and torque over a wide speed range. Units operate on ac supply voltages of 90 to 240 Vac and wire directly to 120 or 220 Vac line voltages to eliminate dc power supply requirements. The drives internally convert ac line voltages to high dc bus voltages to drive large step motors at maximum power.

Available in two models, the STRAC2 provides up to 2.2 A/phase while the STRAC8 provides up to 8.0 A/phase. Every stepper drive in the STR Series operates in step and direction or pulse/pulse control mode. Selecting between the two modes is simple by moving a jumper located under the drive cover or via dip switch on the front panel. Each drive microsteps to 25,000 steps/rev with a 1.8° step motor (1/125 step) even when command pulses are low resolution – thanks to a proprietary step smoothing filter. Users can set up drive parameters – including motor selection, current, and step resolution – using dip or rotary switches. No software is required.

The STRAC Stepper Drives are UL Recognized, CE certified, and RoHS compliant. Applied Motion Products offers a full complement of NEMA 23 and 34 frame step motors optimized for use with these new ac-powered drives.

For more information on the STRAC Stepper Drives, visit www.applied-motion.com.

Leave a Reply

You must be logged in to post a comment.