Sizing a motor for a servo application requires evaluating the move profile and torque requirements to determine the mechanical demands of the system, such as maximum velocity and acceleration, RMS and peak torque values, and load-to-motor inertia match. Once the motor is chosen, the next step is to select a drive.

On the surface, selecting servo drives (also called servo amplifiers) may seem to be a matter of simply matching drive voltage and current output to the motor’s requirements. But there are many factors that need to be considered to ensure the drive operates satisfactorily within the complete servo system. While some applications may require more specialized functions from the drive, here are nine factors that guide the selection of a servo drive for most applications.

1. Motor types commonly paired with servo drives

A servo drive can be used with any motor that operates in a closed-loop system — including stepper, induction, and asynchronous — but the two most common types of motors that are paired with servo drives are brushless DC motors and synchronous AC motors. Of these, synchronous ac motors are more common in motion control applications.

2. Commutation prompted by the servo drive

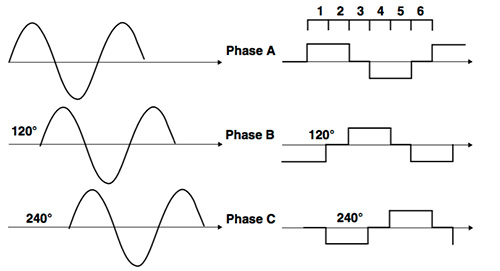

The type of commutation required by the drive depends on the type of motor being driven and the application’s sensitivity to torque ripple. Brushless DC motors can operate with either trapezoidal or sinusoidal commutation, while AC synchronous motors use sinusoidal commutation. Trapezoidal commutation (also called six-step commutation) is the simpler method, using three Hall sensors to determine the commutation sequence. But it produces high torque ripple.

Sinusoidal commutation virtually eliminates torque ripple and provides more precise control by continuously varying the current supplied to the motor windings. However, it requires a high-resolution feedback device to track rotor position.

3. Feedback

Servo systems require feedback in order to provide closed-loop operation and detect and correct any errors in the motor’s actual position, torque, or velocity. This feedback can be provided by Hall sensors, resolvers, or encoders, although most high-end systems use a resolver or an encoder. Regardless of the feedback mechanism, the drive must be compatible with its signal to process it and communicate it to the controller.

4. Voltage and current

The most basic requirement of the motor-drive relationship is that the power from the drive — maximum voltage, continuous current, and peak current — must be sufficient to produce the mechanical output required by the motor — torque, speed, and position. Because the operation of the motor and the drive are co-dependent, manufacturers provide torque-speed curves that define the performance of specific motor-drive combinations.

5. Operating mode

Servo control loops within the drive are used for controlling torque, velocity, or position (or a combination of the three). While all servo drives incorporate a torque control loop and a velocity control loop, only digital drives can provide position control.

6. Analog or digital

Traditional servo drives were analog and converted ±10-Volt signals from the controller to current commands for the motor to control torque or velocity. In order to tune an analog drive, gain values and other parameters are set via potentiometers. With newer digital drives, the command can be executed by either digital or analog inputs, and tuning is done via software.

Along with torque, velocity, and position loops, digital drives can also manage higher-level functionality, such as path generation. Digital drives are also capable of monitoring internal functions of the drive (such as following error) and providing more detailed fault diagnostics.

7. Communication

In order for the drive and controller to “talk” to each other, they must have a common language. To accomplish this, servo drives are offered with a variety of communication protocols, from basic serial links, such as RS485, to more advanced protocols, such as traditional fieldbus networks (DeviceNet, for example) or Ethernet protocols.

The choice of communication protocol will largely depend on the required communication speed, whether there is a master-slave arrangement between multiple drives, and in some cases, the type of controller being used.

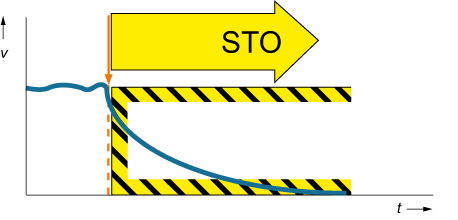

8. Integrated safety

Functional safety is now mandated on many types of machines and is governed by the EN/IEC 62061 and EN/ISO 13849-1 safety standards. To comply with these standards, safety functions, such as Safe Torque Off (STO) and Safe Stop 1 (SS1), are integrated into many higher-level drives.

9. Servo-drive mounting type

For industrial applications, servo drives are for the most part either panel-mounted or PCB-mounted. Panel-mounted drives often install into a control cabinet where they are protected from environmental hazards and can be externally cooled.

In contrast, PCB-mounted drives (also referred to as plug-in drives) provide a compact solution for direct integration onto a PCB. These plug-in drives are commonly used in high-volume OEM applications.

Leave a Reply

You must be logged in to post a comment.