ABM Drives Suzhou Co. Ltd. recently doubled production in China of its self-powered hub-wheel drive.

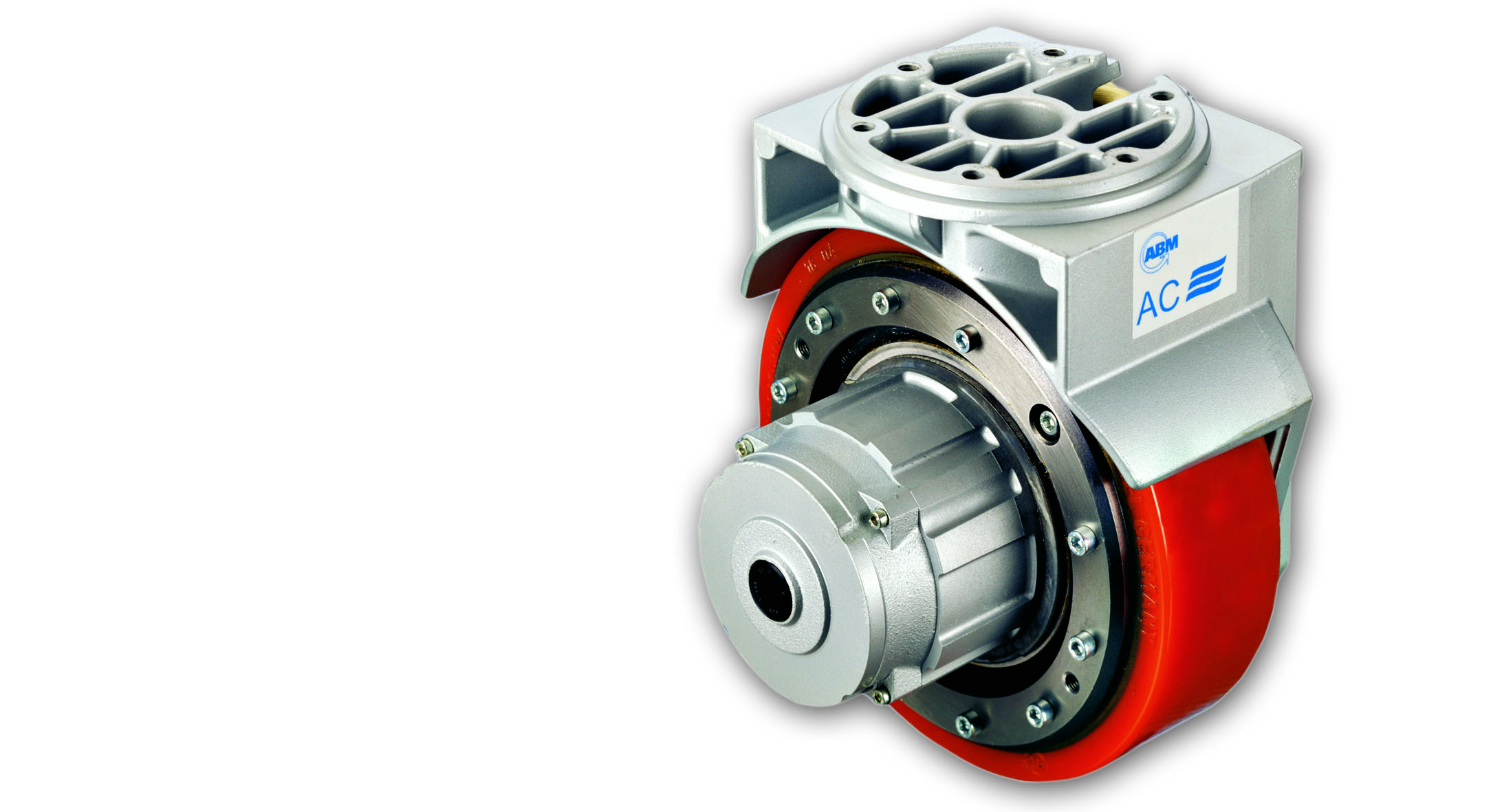

Offered as a 0.6-kW version, this powered hub wheel drive package includes the wheel with tire, ac motor, gearbox and brake. Typical applications include moving 1,000 to 5,000 pounds at speeds of 1.5 to 2.5 mph. The max wheel diameter is 230 mm. This is one of the most frequently sold products of ABM Drives Suzhou Co. Ltd. Revenue of the hub wheel drive is in the five-digit range. More after the jump.

More than ten years ago, in June 2007, ABM Greiffenberger Antriebstechnik GmbH founded its subsidiary ABM Drives Suzhou Co. Ltd. in the Chinese city of Suzhou, near Shanghai. ABM Greiffenberger went to China to better serve customers worldwide; to improve response and delivery times; to ensure quick service; and to strengthen ABM’s position in the global market. Today, there are 27 employees working in sales, purchasing and production in Suzhou; 2017 sales are at €13 million.

By the end of August 2017, ABM will move to a new and larger 3,200 m3 facility.

“The old building is bursting at the seams, so the move is needed to facilitate our best future prospects,” said Robert Lackermeier CEO of ABM Greiffenberger Antriebstechnik. “At the new facility, we’ll build an expanded range of products for the Chinese market and add new production processes. This will further strengthen our position.”

“We have established ourselves very well in the Chinese market. We are offering comprehensive service with short response times because our employees are quickly on site,” added Bernd Hauenstein, General Manager of ABM Drives (Suzhou) Co, Ltd. “The production in Suzhou ensures short delivery times. We are producing a very high quality which meets German and international standards.”

In fact, the Chinese crane builder Weihua Group recently honored ABM as an Outstanding Supplier in recognition of ABM’s quality, innovation ability, and delivery reliability. ABM Greiffenberger supplies Weihua with hoist and travel drives for hoist technology.

At several national and international production sites, ABM manufactures an average of about 300,000 drive units annually. It’s an ABM goal to penetrate the focused markets of hoist technology, conveyor technology, storage logistics, material handling, e-mobility, and renewable energies more intensively. The company also aims to supply to manufacturers of construction and textile machinery. For more information, visit abm-drives.com.

ABM DRIVES INC. engineers and manufacturers high-performance motor, gearbox, brake and frequency inverter setups for machines, plants and mobile devices in hoisting technology, warehousing, material handling, electric vehicles, biomass heating systems, wind turbines and many other markets. Founded in 1927, the company belongs to the Senata Group with an annual turnover of nearly €400 million and more than 2,000 employees. Approximately 300,000 drive units are produced annually. In-house manufacturing includes tool-and-die design, aluminum-casting foundry, CNC housing machining, manufacturer of shafts, cutting of gear teeth, motor development technology, assembly and final testing.

Leave a Reply

You must be logged in to post a comment.