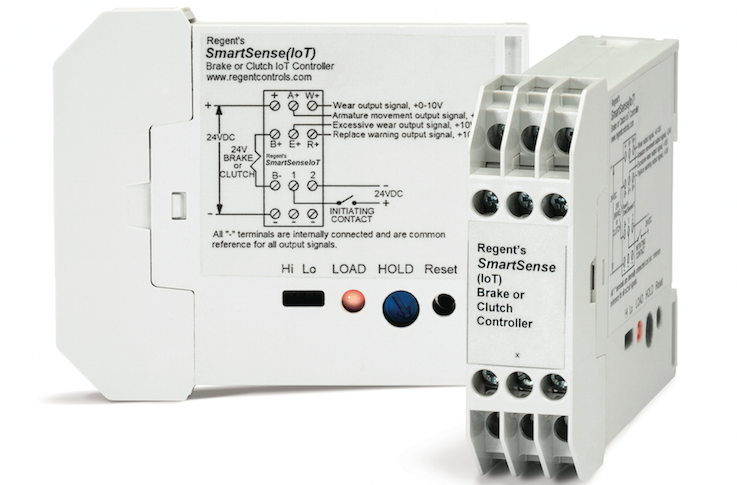

Regent Controls, a Carlyle Johnson Company, has introduced the SmartSense(IoT), a sensorless controller for clutches and brakes in industrial Internet of Things systems. The SmartSense(IoT) provides real-time information and insights on a clutch or brake’s functional health and operation, with data that allows users to optimize maintenance, lifespan, power consumption and performance.

“Our SmartSense product line has really been a breakthrough in clutch and brake monitoring, and our customers have reported great success in their ability to improve performance and plan maintenance,” according to company spokesman Brian Bylo. “With this new product designed for Internet of Things applications, we expect the same results – helping customers lower costs, improve operating efficiency, eliminate risks and reduce downtime.”

The SmartSense(IoT) provides a variety of data in real-time, including: the percentage of wear; an alert when an 80% wear threshold has been reached; an excessive wear warning (indicating an anomaly in the drive system and corresponding components compared to the previous 3 braking or clutching cycles); and an armature motion indicator which helps to eliminate overlap between clutch or brake disengagement and motor start times.

The controller also helps improve clutch and brake performance. After installation, the user manually sets the clutch or brake’s holding voltage or sets the maintained threshold voltage when disengaged. The SmartSense(IoT) then monitors operation, automatically reducing power to an adjustable holding voltage when the clutch or brake is in use, reducing power requirements, reducing heat and optimizing engagement cycles.

As part of a closed-loop system, the SmartSense(IoT) power supply will automatically adjust the voltage drawn based on armature movement. This helps to compensate for wear and temperature changes in the clutch or brake, and allows the unit to provide accurate information. This furthers performance optimizations compared to open-loop clutch and brake systems, which typically require a user to compensate for these affects.

For more information, visit www.regentcontrols.com.

Leave a Reply

You must be logged in to post a comment.