As in years past, the editors at Motion Control Tips have once again sifted through the data to see what stories our readers liked the most in 2023. Some of the most popular stories were ones that reported on automation and motion component trends, as well as stories on gearing and mechatronics.

Here are the top 5 stories we published in 2023 on Motion Control Tips.

#5 The latest developments in fast food automation

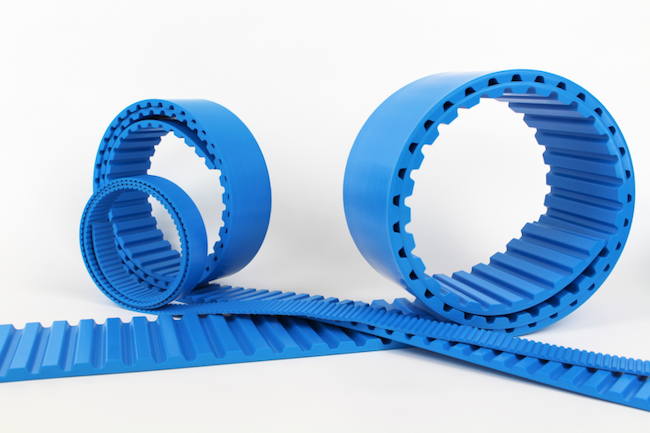

Fast-food restaurants across the globe are pondering ways to automate certain tasks or entire assembly lines to provide continuous service at low costs. They’re investigating new motion components, HMIs, and robotics for automated solutions to keep operations up and protect against future labor fluctuations.

Design World editors asked industry experts to weigh in on how robots, conveyors, linear actuators, and other motion components play a role in automated fast-food production.

#4 Five applications where smart mechatronics make sense

Smart mechatronics technology is being applied in a variety of industries, where the benefits include increased efficiency, improved accuracy, and enhanced productivity.

This technology has proven to be effective in improving the efficiency and effectiveness of many industrial processes. This article takes a look at five applications where smart mechatronics make sense.

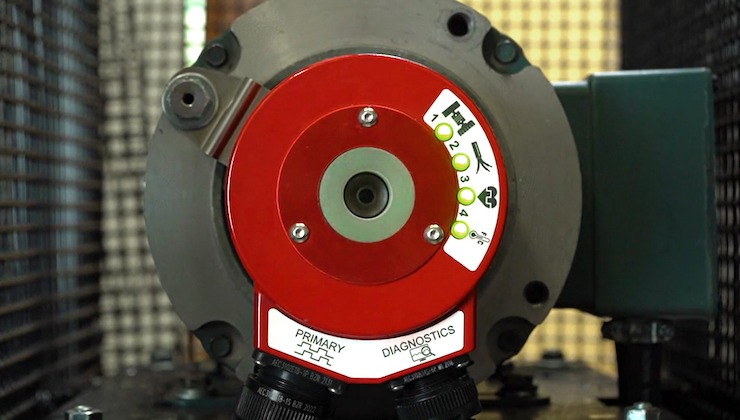

#3 Encoder, sensor, and feedback trends

Earlier this year, a number of encoder, sensor, and feedback industry experts answered several questions about trends they are seeing with these components and the industry more generally. This article summarizes what they had to say.

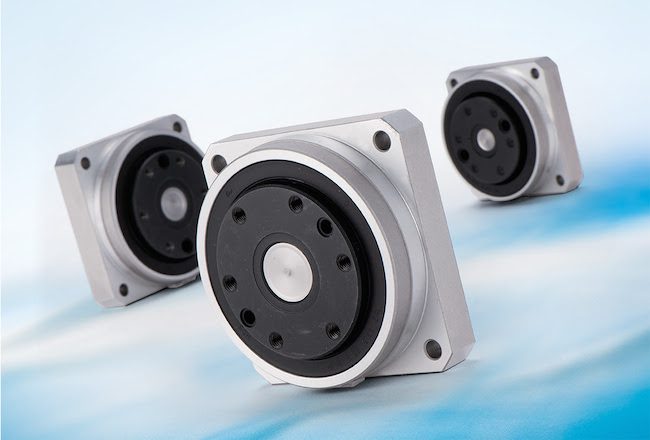

#2 How to get zero backlash out of gearing?

The kind of gears used in gearmotors have an impact on the available torque, but also on things like noise levels and accuracy. In fact, one of the more common sources of inaccuracy in gearmotors is due to gear backlash. So reducing the amount of backlash will lead to a more accurate gearmotor.

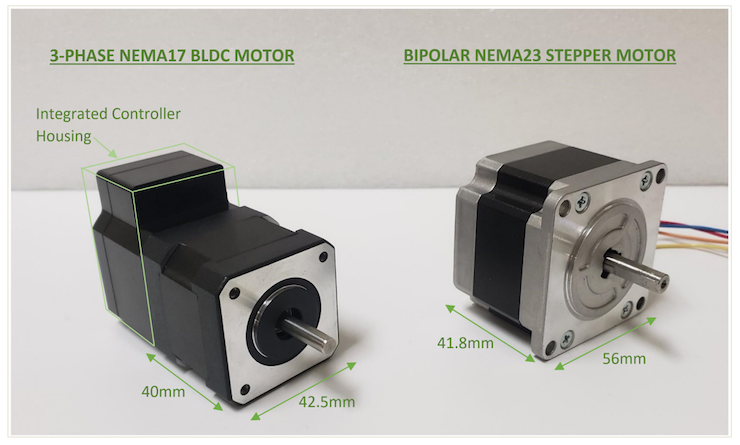

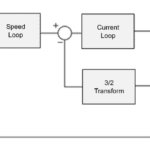

#1 Comparing stepper and brushless dc motors

For engineers and designers working on modern-day motion and other industrial applications, it’s vital to understand the advantages and disadvantages of stepper and brushless dc (BLDC) motors. This article looks at a widely used hybrid stepper motor and a 3-phase BLDC motor and compare both devices. It consider the working principles of these motors (physical size and power density) and make observations about the acceleration and noise aspects of each motor. Experiments performed under various load conditions reveal changes in power, efficiency, and temperature.

Leave a Reply

You must be logged in to post a comment.