There are numerous interpretations of what the motion control market entails in terms of products included and industries served, but there are some commonalities among the various definitions.

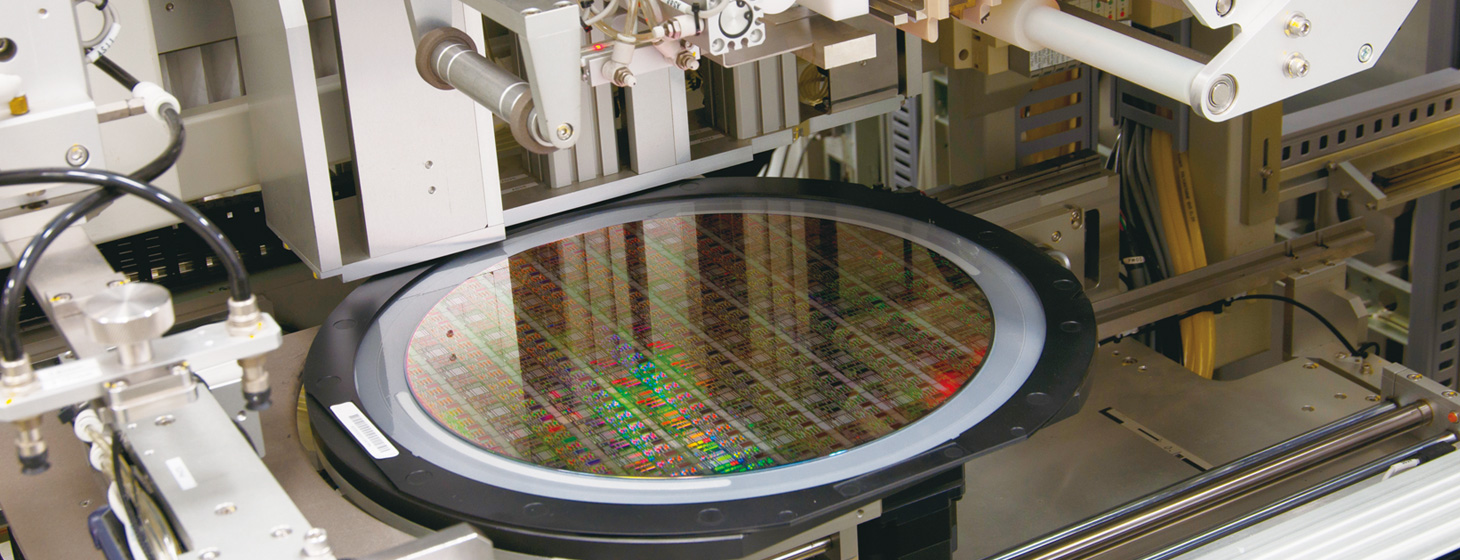

First, a motion control system includes at least three basic components — a motor, a drive, and a controller. Second, motion control systems are primarily used in discrete industries such as packaging and semiconductor manufacturing, as opposed to process industries such as chemical manufacturing and power generation.

No matter how it’s defined, the motion control market is huge, ranging anywhere from $9 billion to $12 billion, depending on which products and industries are included. With very large industries, the number of market players and drivers add significant uncertainty and complexity to everything from product planning to market analysis. One way to address this complexity is to divide the market into smaller segments, based on similar product groups or industry categories. Take, for example, the passenger vehicle market. Most passenger vehicle manufacturers and industry analysts recognize at least three subsegments of the market — cars, trucks, and sport-utility vehicles (and most break the market into even smaller segments).

Similarly, to address the size and complexity of the motion control market, manufacturers and analysts have divided the market into two subsegments: general motion control (GMC) and computer numerical control (CNC).

Most industry statistics show that general motion control (GMC) accounts for just over 50 percent of the overall motion control market, while computer numerical control (CNC) accounts for just under half.

The basic function of a general motion control system is to control the acceleration, speed, and/or position of a single motor or of multiple coordinated motors. From an OEM or end-user perspective, GMC systems provide general-purpose, coordinated motion. They are typically used in the industrial automation market, but exclude military, aerospace, and consumer products applications.

In contrast, computer numerical control (CNC) systems provide multi-axis coordinated motion and are typically used for contoured moves that require interpolation. CNC systems are often designed to meet the specific requirements of the machine tool industry, although they can be used in other industries.

Image credit: Gebr. Heller Maschinenfabrik GmbH

Note that GMC systems can also be used in machine tool applications, especially for processes such as loading/unloading parts and for coarse positioning moves not involved with actual material processing.

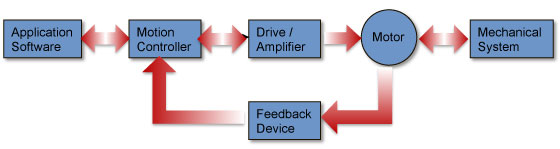

One thing that is not widely agreed upon among industry analysts and manufacturers is which components are included in a general motion control system. Case in point, ARC Advisory Group considers the components that make up a GMC system to be the motor, drive, controller, and any integrated feedback devices. Siemens, a leading manufacturer of motion control components and systems, includes two additional components in their definition: software that is developed specifically for the application (which, in some cases, would be included in the controller in ARC’s definition) and the mechanical system — belt, chain, ball screw, rack and pinion, etc. — that transmits work to the load.

Image credit: Siemens Industry, Inc.

It is recognized, however, that general motion control systems are most often based on servo motors and drives, although some manufacturers and analysts consider stepper-based systems to be part of the GMC market. (It could be argued that open-loop stepper systems — which are by far more common than closed-loop steppers — do not qualify as GMC systems since they don’t rely on a feedback device.) The most common definitions of general motion control also include both stand-alone drive amplifiers and motor-integrated drives, as well as stand-alone, PLC-based, and PC-based motion controllers.

Don’t confuse the term “general motion control,” as described here, with the term “generic motion control,” which is a software platform from B&R Automation.

Leave a Reply

You must be logged in to post a comment.