Operating systems manage the communication between hardware and software in devices such as servers, computers, mobile phones, and embedded systems. Most personal computers and laptops use either Microsoft’s Windows operating system or Apple’s macOS, and mobile devices such as phones and tablets primarily use Google’s Android operating system or Apple’s iOS. In the industrial world, servers, HMIs, and enterprise systems have historically been run on Windows operating systems, primarily because of Windows’ familiarity, availability, and ease-of-use. But there’s another operating system that’s gaining traction in motion control applications: Linux.

Since its introduction in 1991, the Linux operating system has consistently been praised for its security, stability, and reliability. Although Linux isn’t a household name like Windows or Android, Linux operating systems work behind the scenes in many of the products we use every day, including Roku devices, the Amazon Kindle, and many smart appliances. The Android operating system is even built on the Linux kernel.

Just for fun: check out these 25 Awesome Things Powered by Linux.

One of the key attributes that makes Linux so attractive is that it’s open-source, meaning the source code is freely available and has no licensing fees. And as an open-source software, users can modify it to suit their specific needs. In fact, dozens of modifications of Linux have become standard offerings from third parties. (These modifications are often referred to as “distributions,” or “distros,” for short.)

While Linux made significant headway in consumer and business environments, compatibility issues limited its adoption by manufacturers of industrial equipment. But the introduction of OPC UA (Open Platform Communications Unified Architecture) has made the use of Linux a reality for industrial applications, by enabling devices running on different operating systems (Windows, macOS, and Linux) to communicate with each other. So networks that integrate OPC UA — either alone or in conjunction with other Industrial Ethernet communication protocols — can implement systems running on Linux without worrying about compatibility and communication with other parts of the enterprise.

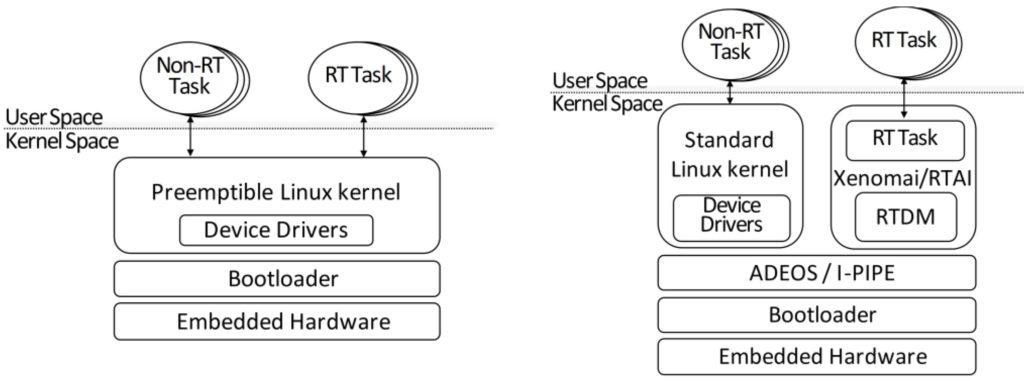

Another drawback of Linux operating systems, historically, was their lack of real-time capabilities. However, two solutions have been introduced to address the need for real-time operation, particularly for industrial applications. The first is a patch, or modification, of the Linux kernel (the core of the operating system that manages communications and resources), referred to as PREEMPT_RT. Simply put, the patch allows threads to be preempted if a higher priority thread comes along.

The other solution — known as Xenomai — is a real-time extension to Linux. Xenomai takes a dual-kernel approach, with a “co-kernel” working alongside the Linux kernel. The co-kernel handles real-time tasks and the Linux kernel handles those that don’t require real-time performance.

Image credit: Delgado, Park, Choi

With solutions to compatibility issues and real-time communication now readily available, the list of motion control devices that run on Linux is growing rapidly. For example, Bosch Rexroth’s new ctrlX Automation software platform is based on the Ubuntu distribution of Linux. Rexroth chose Linux as the operating system due to its openness and flexibility, including the fact that it allows programmers to use modern languages like C/C++, Javascript, and Python, as well as the traditional IEC 61131-3 languages.

In the hardware space, Opto22’s groov EPIC controller for edge devices is based on a real-time version of Linux, and since it’s open-source, users can run their own custom-developed applications. Wago’s series PFC100 and PFC200 controllers also use a real-time Linux operating system.

And these are just a few of many examples. To see more manufacturers and products that integrate or support Linux, go to the Design World online site and search for “Linux.”

Feature image credit: Ewing, Budig, LeSage

Leave a Reply

You must be logged in to post a comment.