In manufacturing processes and plants, multiple Industrial Ethernet protocols — such as EtherNet/IP, PROFINET, or EtherCAT — are used across different networks to meet specific topology requirements, communication speeds, or latency guarantees. And although these communication protocols are open, they’re often incompatible, resulting in fragmented networks that can’t “speak” to each other.

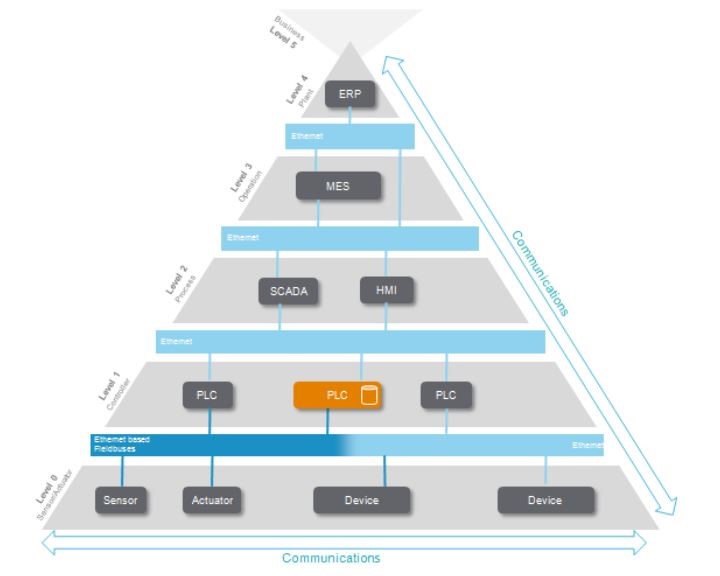

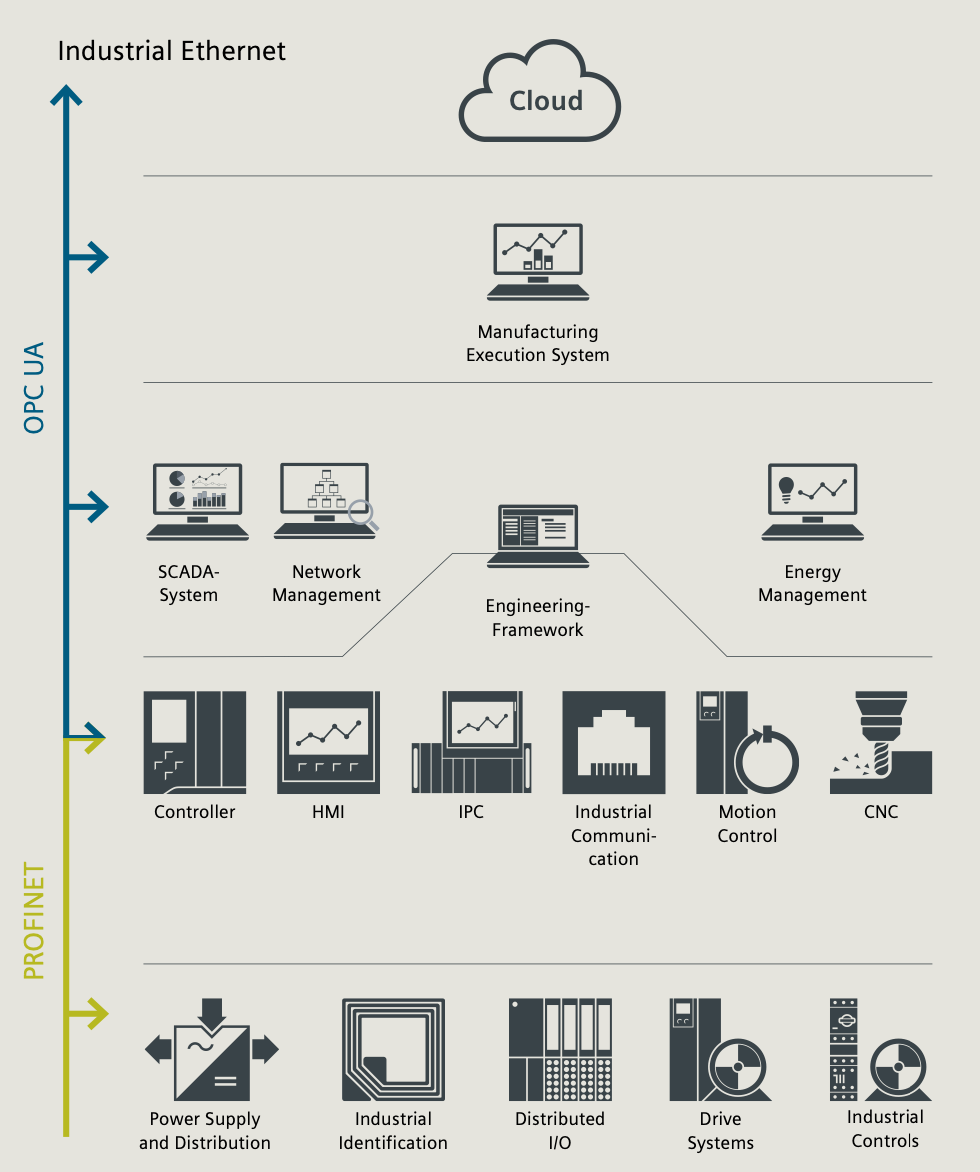

OPC UA (Open Platform Communications Unified Architecture) was developed to solve this problem by allowing industrial devices operating with different protocols and on different platforms (Windows, Mac, or Linux, for example) to communicate with each other. And OPC UA goes beyond Industrial Ethernet in its reach, including devices all the way from the lowest level of the automation pyramid — field devices that deal with real-world data, such as sensors, actuators, and motors — to the highest levels, including such as SCADA (supervisory control and data acquisition), MES (manufacturing execution systems), and ERP (enterprise resource planning) systems, as well as to the cloud.

Image credit: Schneider Electric

The OPC standard is series of specifications, managed by the OPC Foundation, that define the interface between clients and servers or servers and servers, including access to real-time data, monitoring of alarms and events, access to historical data, and other applications. The original OPC standard, now referred to as OPC Classic, was restricted to Microsoft Windows operating systems. With the introduction of OPC UA, the technology became platform-independent.

The key behind OPC UA’s ability to allow networks from different vendors and on different platforms to communicate is its method of data modeling. OPC UA keeps not just the raw data itself (the value “15,” for example), but also its context and any limits or parameters around the data (“degrees Celsius,” for example). With standardized, semantic descriptions, any OPC UA-enabled device can locate and use the data it needs. Four of the most important data models in OPC UA are data access (DA), alarms and conditions (AC), historical access (HA), and programs (Prog). These foundational models can also be used as the basis for other application- or process-specific data models.

OPC was originally introduced with a client-server communication model, but in 2018, a publish-subscribe (aka PubSub) extension was made available. The client-server version deals with point-to-point communication and is based on TCP/IP, so it isn’t real-time capable. The PubSub version deals with one-to-many communications (one publisher to any number of subscribers) and can be implemented with time-sensitive networking, allowing OPC UA to provide hard real-time communication — with cycle times, latency, and jitter specifications that rival deterministic Industrial Ethernet protocols.

OPC UA and Industrial Ethernet

This begs the question: Will OPC UA replace Industrial Ethernet?

While there is clearly overlap between OPC UA with TSN and the deterministic, real-time Industrial Ethernet protocols, it seems unlikely that OPC UA will replace Industrial Ethernet in the immediate future. One reason is because the two technologies are focused on different outcomes. The strength of OPC UA, even with real-time communication enabled by TSN, is that it allows different networks to communicate, especially at the factory- and enterprise-level. Industrial Ethernet, on the other hand, is primarily designed for communication between field devices and controllers. The two can, and likely will, coexist for a long while.

However, as Industry 4.0 and IIoT (industrial internet of things) implementations become more widespread, it is possible — and according to some experts, likely — that OPC UA with TSN will begin to displace Industrial Ethernet in those applications.

In fact, Microsoft (a long-time partner of the OPC Foundation) claims that OPC UA is “widely recognized as the key communication and data modeling technology for Industry 4.0.” Both Industry 4.0 and IIoT require that industrial networks be integrated both horizontally (machine-to-machine) and vertically (field devices to plant-level and enterprise-level systems), with large numbers of devices to be managed and, in turn, huge amounts of data to be processed.

OPC UA enables both horizontal and vertical integration, as well as the communication and management of devices and data from every part of the network, from the field to the enterprise. And it does so in a platform- and vendor-independent solution with security (methods of managing access, authentication, message signing, encryption, and logging) built-in.

This video from the OPC Foundation gives a brief overview of OPC UA.

Leave a Reply

You must be logged in to post a comment.