WITTENSTEIN, manufacturer of motion-control products, servo systems, and mechatronic systems, has now expanded its Galaxie system product line to include more sizes, a hypoid version, and a new ultra-flat version. The new products will be launched at the upcoming Hannover Messe Fair in Germany this April 23 to 27, 2018.

The expanded Galaxie product line includes:

- The compact Galaxie D in size 085 for use in smaller cutting heads or handling axes where special requirements apply regarding torsional rigidity and freedom from backlash.

- The new ultra-flat Galaxie DF in sizes 110 and 135, which saves up to 30% of the normal installation length.

- The Galaxie GH with its optional right-angle input stage.

Several moving demos will demonstrate how the flexible encoder interfaces allow Galaxie to be easily integrated into existing machine concepts. These demos will show the drive system in action, highlighting Galaxie products’ technological superiority in machine tools, cutting heads and robot welding guns, to name but a few.

For the first time, WITTENSTEIN will also show how operating data can be transmitted to an IoT cloud using a Galaxie Drive System equipped with sensors.

This data can be accessed anywhere and on any device throughout the drive lifecycle, regardless of the control system.

High-performance engineering for dynamic performance

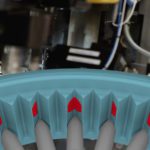

The Galaxie includes dynamic teeth instead of a rigid gear ring, the tangential and hydrodynamic tooth contact over the full surface when loaded and the new type of bearing with a segmented outer race ring. All of this adds up to a novel design principle, with the result that Galaxie is clearly superior to other, established principles in all key technical disciplines compared to the market standard. In short, Galaxie is a disruptive innovation causing displacement of traditional design. For more information, visit wittenstein-us.com.

Leave a Reply

You must be logged in to post a comment.