Industrial automation software developer Copia Automation announced the release of its newest product DeviceLink , delivering automated backup and change detection for industrial control devices. DeviceLink extends the value of Copia’s source control platform. Cloud-hosted and Git-based, Copia empowers controls engineers to unlock the advantages of DevOps workflows in driving greater team efficiency, code quality, and operational uptime.

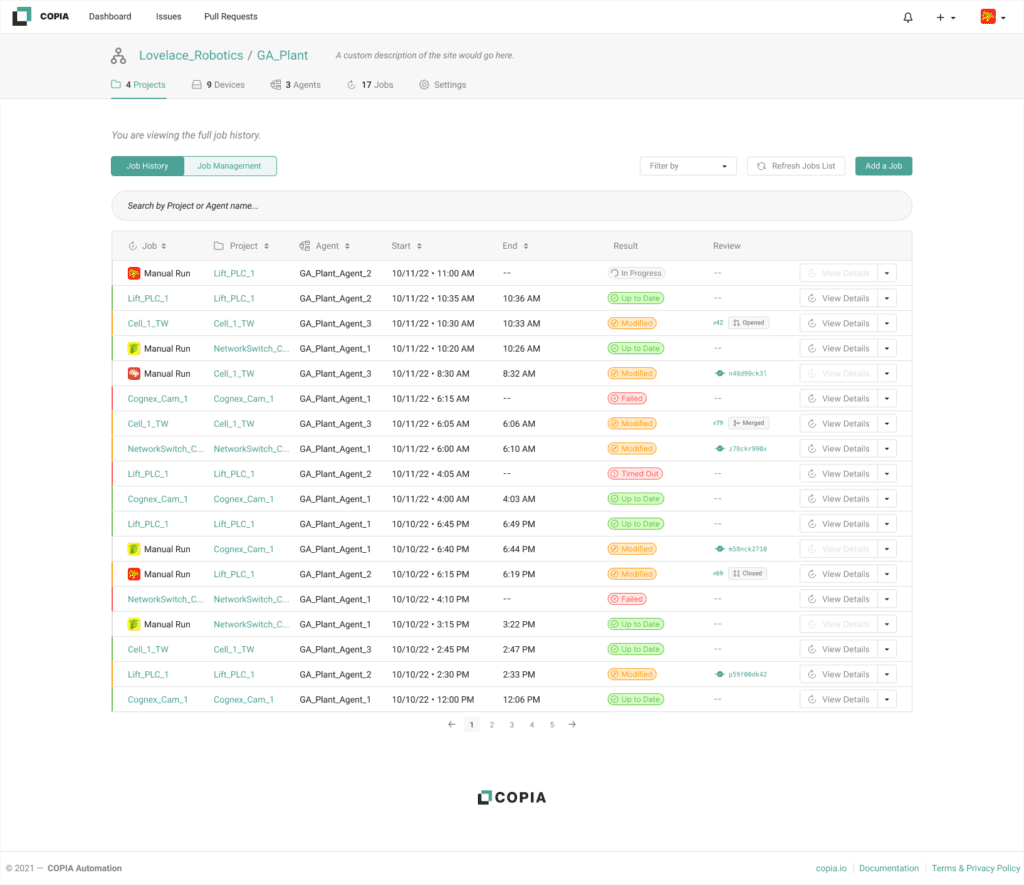

“Once a machine is deployed to the factory floor, most manufacturers lose visibility into how control programs change. Teams are focused on keeping machines running and not documenting the code tweaks and edits that always occur over time,” explains Copia CEO Adam Gluck. “DeviceLink automatically backs up these control programs to one centralized location giving teams code security, up-to-date visibility, and most important — change traceability.”

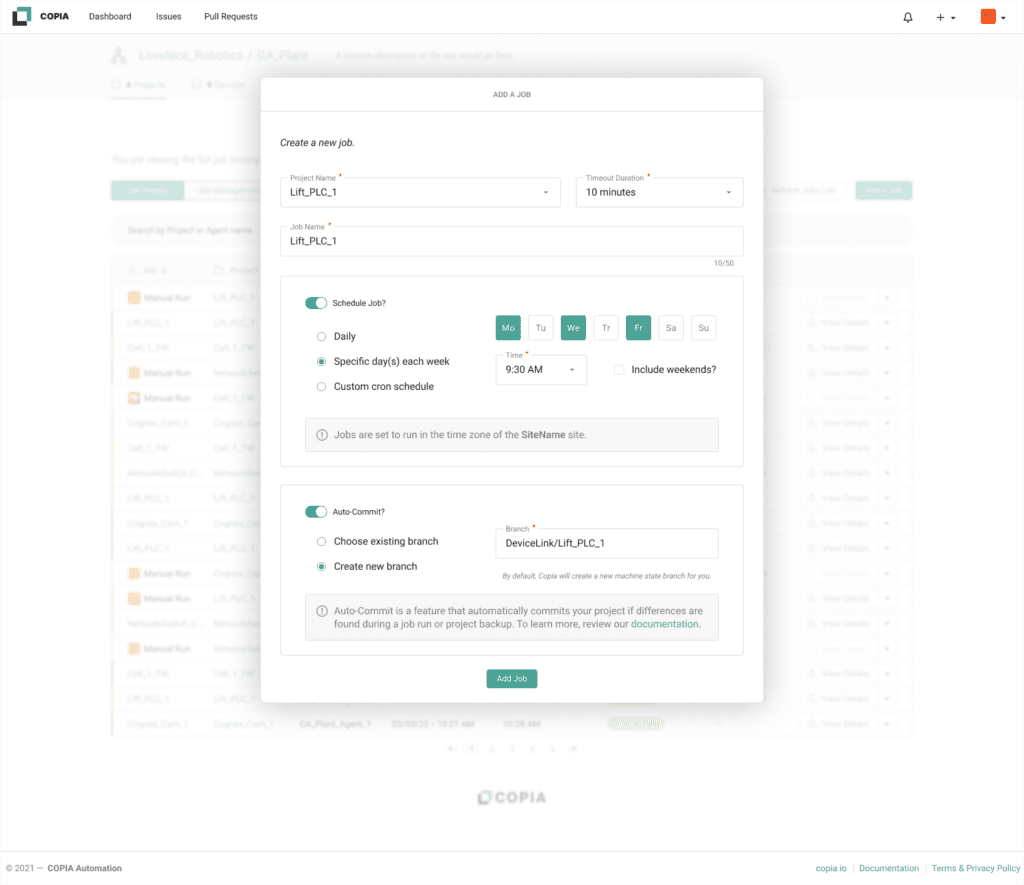

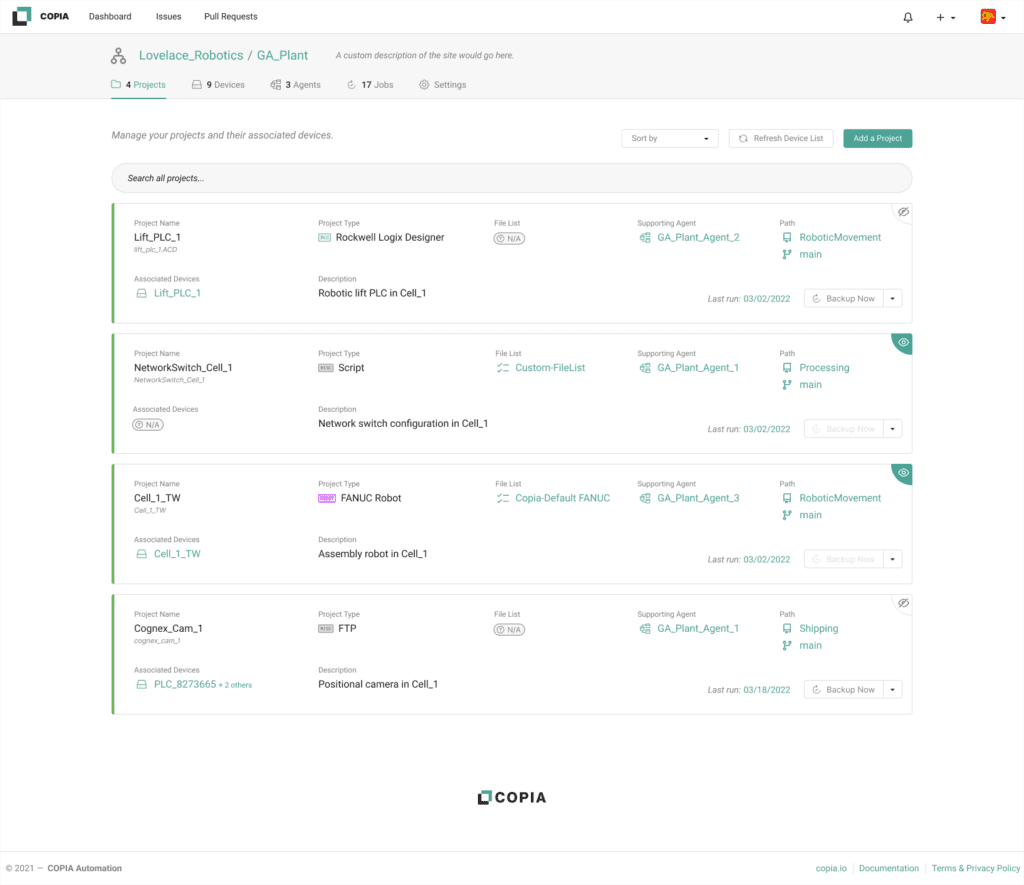

Copia’s DeviceLink works with Allen-Bradley, CODESYS, Beckhoff, and FANUC devices and can schedule code backups at any time or frequency. FTP and Bash scripting are also supported, and Siemens device support is coming soon. Once the code is backed up, DeviceLink will compare it to the last known version. When changes are detected, it will create a new committed version. If desired, the new edits can be reviewed, approved, and merged into any ongoing development code.

“Regardless of how much equipment we’re managing and how many sites that equipment is spread across, DeviceLink shows us all the live control code in one place,” says Kellen Murray, founder at Konductive. “We always have up-to-date restore points in case of failures and are proactively alerted to unauthorized changes.”

Device Link builds on the power of Copia Automations Git-based source control and its ability to render control programs in standard formats, including ladder logic (LD), function block diagram (FBD), and structured text. As changes occur, Copia can highlight the difference between versions.

“Not only do one gain knowledge of when PLC or robotic code changes, but one can also immediately see the exact edits,” states Gluck. “This insight is crucial in determining whether the change was authorized and must be the restore point moving forward.”

DeviceLink adds to Copia’s mission of bringing modern DevOps practices to industrial automation, equipping control engineers with the same game-changing workflows used in traditional software development. The Git-based source controls allow engineers to work simultaneously on the same codebase, review code efficiently, and ensure that all changes are documented and accessible.

“By integrating Copia Automation’s platform into the daily workflow, we can better use engineering resources to handle more projects and ensure the highest quality code development,” Murray explains. “DeviceLink builds on these benefits by providing the same level of visibility into the control programs running on the factory floor.”

To learn more about Copia Automation, visit www.copia.io.

Leave a Reply

You must be logged in to post a comment.