by Adriano De Rosa, IC Architect, Micronas || Motor drive solutions using brushless dc motors are increasing, thanks to the declining cost of electronics. Highly integrated, single-chip controllers are helping drive the trend.

Advances in semiconductor integration are spurring new motor drive designs, including more intelligent drives. The various options for semiconductor integration are opening up an ever-growing array of applications for distributed intelligent small motor drive solutions. These include brushless dc (BLDC) motors, permanent magnet synchronous motors (PMSM) and stepper motors. Because of their technical advantages and increased efficiency, these types of motors are replacing brush-type motors in many existing applications.

The automobile industry is just one example. Typically, automotive components must support low system cost, be small, light, reliable and highly efficient. Reducing exhaust emissions and lowering fuel consumption is also important. The need for drive concepts that work with a wide range of motors, and the extreme demands made on efficiency, system design and networking options have a major impact on actuator electronics.

For many applications, the design-in time can be reduced because complete platforms of small motors can be developed using a single-chip solution. Different motor types and properties can be tailored to by adapting the software. Today’s brush-type dc motor system can be replaced by a BLDC motor system that on the outside looks like a conventional motor, but inside provides advantages needed to realize intelligent motion control.

Self-diagnosis and functional safety increasingly play an important role. Drives with “integrated intelligence” by means of electronics can provide this diagnostic feature. For example, changing motor properties can be tracked and stored by the electronics and adjusted to a certain extent.

Adapting the software allows a large number of functions and applications to be addressed. Designers can efficiently equip a complete platform of actuators with just one type of controller. The small number of discrete components and high integration provide a great degree of miniaturization. The high level of reusability of hardware and software permits quick responses to changes in application requirements.

The BLDC motor market

The level of adoption of BLDC motor technology is increasing. Many automotive functions, such as fuel or water pumps, curve light, head-lamp leveling and others, are converting from brush-type dc motors or stepper motors to BLDC motor technology. If nothing else, the old orthodoxy that the electronics to control the motor are too expensive compared to the price of the motor itself is becoming less valid every day. Furthermore, BLDC motor advantages can significantly enhance other system properties.

When looking at motion control systems, including brush-type dc motors, it’s obvious that control is less complex compared to a BLDC motor. Engineers with little experience in BLDC motor control system design often fear that they will have difficulty converting to BLDC motor technology, even though they know about the advantages. Complex electronics and the programming of such a system are often thought to be a barrier.

However, the transition to BLDC motors is not necessarily difficult. Using a single-chip solution greatly simplifies the electronic circuit.

Benefits of single-chip architecture

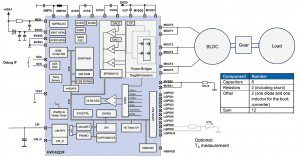

The new Micronas High-Voltage Controllers (HVCs) allow systems with highly integrated motor drive electronics to achieve the performance potential of modern, permanently excited dc motors. The HVC 4223F is an integrated microcomputer system with peripheral modules for directly driving PMSM/BLDC motors and bipolar stepper motors. The programming capability of the peripheral modules and the user-defined software allow the best possible adaptation to the properties and attributes of different drive systems.

The increasing integration density in drives, made possible by the low power/weight ratio (W/kg) of PMSM/BLDC motors, affects the power dissipation, the flexibility of driving circuitry, the selected drive, and the diagnostic options. The high integration density of the electronics requires adapting the thermal operating conditions by means of a target-specified power management. The new HVC family provides many functions that allow this adaptation.

The use of different drive concepts in automotive actuators, for instance, requires the easy adaptation of the motor power bridge and how the bridge is activated. The HVC 4223F addresses this issue with a configurable final output stage, fully integrated and programmable peripheral module, and a powerful ARM Cortex-M3 processor.

The EPWM-Module (Enhanced Pulse-Width Modulation) supports passive and active free-wheeling current patterns (Asynchronous/Synchronous Rectification) for different operating modes and types of motors. The integrated current measurement and the D/A converters allow the programming of nominal current values (for current-controlled micro-stepping, for example). In the PMSM/BLDC motor, without using sensors, the feedback signal of the rotor position can be sent using comparators and integrated star-point references or Hall-effect sensors/encoders.

Algorithms for speed and current control can be quickly executed with the ARM Cortex-M3 CPU—supported by the high-speed A/D converter and adjustable signal paths for voltage and current measurements. The output stage includes overload protection (overvoltage/excess current) and diagnostic functions.

Application example: positioning actuator with BLDC motor

A typical application example only requires 13 components, including the HVC 4223F itself. In many cases, a smaller motor can be used due to better efficiency. The actuators can also be smaller, further reducing material cost. What’s more, the BLDC control system can be programmed to behave like a brush dc motor from outside, with only a voltage and ground supply as connections. This means that existing motion control systems can be upgraded without changing the complete system design. And in the long term, the system can be improved with networking and/or diagnostic functions. Designers don’t have to start from scratch with software development because the existing application notes and demo software can provide an adequate level of functionality.

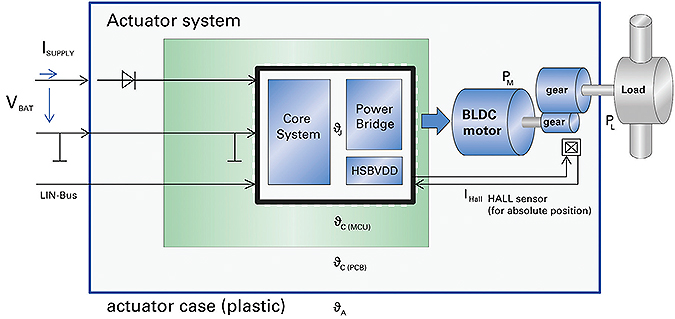

A good example involves positioning actuators. Mechanical actuators for positioning applications usually have to provide a high torque. Typically, a gear is used to obtain low rpm at the load, introducing considerable losses due to friction. In many cases, the actuator must apply a stable holding torque and the actuator shouldn’t lose its last position to avoid calibration runs. Due to weight reduction and space constraints, the motor and electronic geometry plays an important role. The example describes a solution for a single-chip motor actuator with the HVC 4223F driving a BLDC motor in sensor-less six-step commutation with a LIN communication interface.

the HVC 4223F can greatly reduce the number of external components needed. In this example, the complete circuit only requires eight capacitors, two resistors, a diode and an inductor.

The efficient interaction of hardware and software inside a motion control system depends on the distribution of the particular functions of the available chip peripherals. A possible approach for a system includes sensor-less six-step commutation, including rpm and current control, functions for diagnostics, and communication stack. The software architecture can be a simple round-robin with interrupts.

A basic circuit solution for such a system can reduce the number of external components for the motor to a minimum of 12 components. In case of special system ESD and/or EMC requirements, some additional components, like ferrite beads, might be required, for instance, in the dc supply link or LIN signal path.

Micronas

www.micronas.com/en

Leave a Reply

You must be logged in to post a comment.