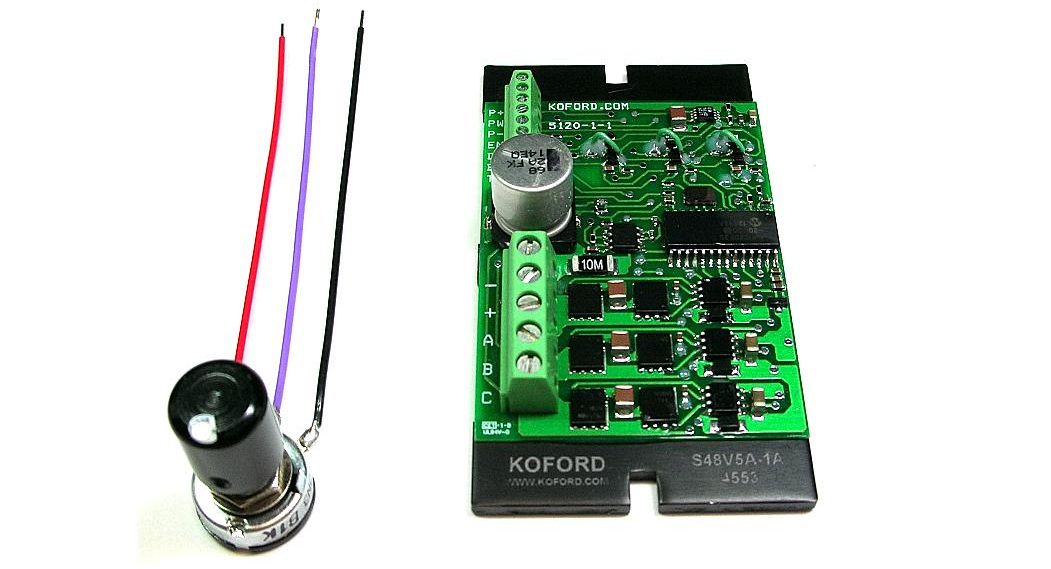

Koford Engineering LLC now sells a line of compact 48-V 5-A brushless motor drives. These drives are suitable for slotless or other low inductance brushless motors and require no external inductors. More after the jump.

They are preprogramed and require no user set up, adjustments or programing. Unlike most drives they can operate at 100% duty cycle. Most brushless drives are limited to 95% and cannot achieve full rated motor performance. Part numbers are available for speed up to 200,000 rpm for a two pole motor or 100,000 rpm for a 4 pole motor. Both two quadrant and four quadrant versions are offered. For four quadrant units which are powered by a power supply and not a battery, braking modules are available to absorb the regenerated energy. This eliminates the need for a relay and resistor for energy absorption.

The drive can be controlled with a speed pot, a 0-5 volt analog or pwm signal, or the unit can be custom programed to run at a fixed speed with only power-ground and motor connections. Product information can be found at www.koford.com.

Leave a Reply

You must be logged in to post a comment.