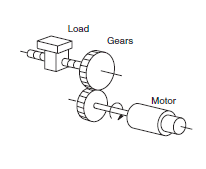

In an earlier article on the impact of gearmotors on the reflected mass inertia from the load, we made some assumptions about the inertia of system components which weren’t explicit and which could lead to error in the calculation and cause problems in an actual application. This came to our attention via a sharp-eyed reader’s comment so to make things right, we’re clarifying a few points to more accurately reflect (sorry for the pun) the nature of inertia calculations.

Specifically, what we left out was the inertia of the gear train as well as any elements of the motor connection system itself. Leaving these inertia values out of the overall calculation produces an incorrect value for overall inertia and can lead to undersizing input torque requirements.

What’s missing from the total system inertia is the inertia of the gears themselves and any other components of the connection system such as couplings. Another factor to keep in mind is that even with the same ratio different types of speed reduction and couplings may have different inertia values.

The key point is this: If the gear reducer is added separately, then the inertia value of the gears (usually provided by the manufacturer) needs to be added into the total system inertia. However, when purchasing a complete gearmotor, check with the manufacturer to determine if the published gearmotor inertia value includes the inertia of the internal gear reducer.

The bottom line is when calculating the total inertia for any motion system, the final value must include the inertia of all rotating parts, including the drive (such as a belt and pulley system, screw, or rack and pinion, etc.), the load being moved, the motor, the gearbox (if used in the system) and the coupling between the load and the motor.

Leave a Reply

You must be logged in to post a comment.