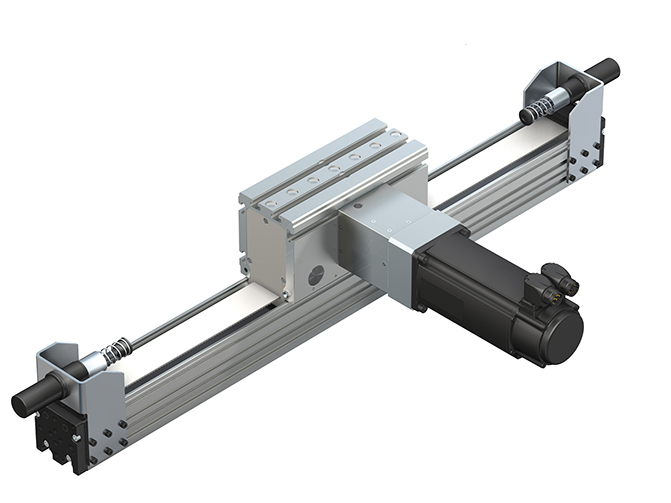

Edited by Mary C. Gannon || Shock and vibration-damping components are as varied as the designs in which they work. That ranges from heavy-duty machine tools to delicate designs that assemble semiconductor components. Addressing these oscillations lets machines run faster, for more throughput and higher-quality (more accurate) moves.

For example, the automotive manufacturing and packaging industries make copious use of mid-bore and smaller-bore hydraulic dampers.

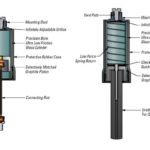

Consider how bottle-blowing machine builders use adjustable shock absorbers instead of rubber bumpers or springs to increase glass and plastic bottle production. The shock absorbers protect the bottle’s neck and opening against stress fracture during manufacturing, even in hot and dirty environments. The shock absorbers in this application sport reinforced bodies to withstand more energy per second as well as Teflon-coated piston rings and piston rod seals formulated to withstand heat. More after the jump.

Shocks and vibration dampers excel in designs that are engineered to avoid the structures’ natural frequencies during operation. Adding mass with heavy bases or mounting machines into steel or concrete flooring is one approach. In applications where this is not possible or sufficient, vibration-isolating components and other passive dampers can absorb or attenuate vibrations. Here, the components bear the whole machine weight to shift excitation off the natural frequency.

As a general rule of thumb, isolators should shift a design’s natural frequency so it’s no more than one-third of the excitation frequency. One caveat is that overly compliant isolators can actually increase the magnitude of motion. One solution where this is an issue is hydraulic or magneto-rheological setups that damp at system natural frequency but isolate like undamped designs.

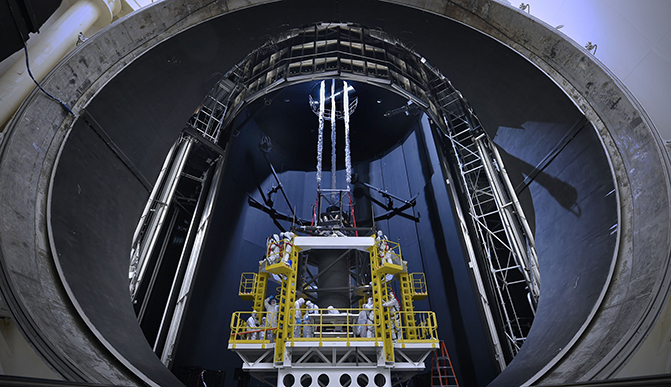

In contrast, active vibration controls use actuators and sensors to counteract vibrations with motion having an out-of-phase frequency. Mechanical passive negative-stiffness vibration isolators from Minus K Technology isolate horizontal and vertical vibrations separately using no air or electricity. Such technology is particularly useful in aerospace and semiconductor applications with nanometer-level and better accuracy demands.

Mechanical subcomponents in the form of wave springs and compliant couplings are still other options to isolate vibrations, in everything from precision electric-motor-driven machinery to those that run off internal-combustion setups.

As mentioned, one semi-active product to damp vibrations is magneto-rheologic fluid from Lord Corp., a blend of magnetic powder in oil, water or glycol that reversibly changes from free-flowing to semi-solid under an electromagnetic field. Particularly useful in automotive applications that must accommodate changing road and driving conditions, magneto-rheologic components can replace traditional hydraulic fluid in shock absorbers.

No matter the subtype, shocks and vibration-damping components have a reputation for being a commodity component. In fact, these devices are highly engineered and customized to very specific loads, impacts and machine geometries, and affect overall equipment performance.

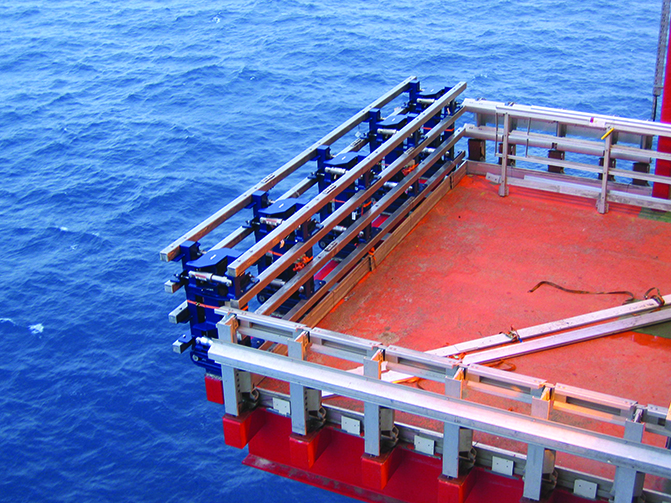

Isolation system manages cargo kinetic energy

Norwegian oil company Statoil’s Gudrun Platform operates in the North Sea’s Gudrun field. The platform operates cranes for around-the-clock cargo handling. As crane operators hoist supplies from ships to the platform, containers (some weighing as much as 8,000 kg) can move toward the Gudron Platform at 3 m/sec.

“Moving equipment from a supply ship onto an offshore platform in difficult conditions requires a highly engineered system of shocks and dampers,” said Tomm Kuran, sales manager for pneumatics at Servi Hydranor AS, a Norwegian distributor of hydraulic and hydraulic-related products. “The Gudrun’s crane operators move food and heavy, expensive equipment for drilling. If an operator mishandles a container, people can be hurt or equipment destroyed.”

“A mishandled container can also halt drilling operations,” said Peter Bauer, managing director for ITT Control Technologies EMEA. Flexible barriers have been used for approximately 10 years on offshore platforms in the North Sea, but they often sustain damage from containers slamming into them.

Engineers came to Servi Hydranor and ITT’s Control Technologies early in the design process of the Gudron Platform with a set of specifications (including environmental conditions) and space limitations. While offshore rig builders know how to stabilize cranes, engineers saw challenges in designing a dampening system for its cargo barrier.

So, the two companies engineered a shock and vibration isolation system that includes highly tuned dampers that absorb the cargo’s kinetic energy. Because of the design, the barrier system handles impact energy several times higher than traditional designs. The companies completed the shock and isolation design work in 2013, and the Gudrun Platform is now in operation.

Leave a Reply

You must be logged in to post a comment.