If you deal with electrical components, including electrical enclosures such as control cabinets, you’re probably familiar with IP (International Protection) ratings, which specify the enclosure’s ability to prevent the ingress of solid objects and liquids. But you may be less familiar with the IK rating system, which defines the enclosure’s ability to protect its components from external mechanical impacts, as measured by the impact energy, in joules.

Image credit: Hoffmann

A joule is a very small amount of energy. A common example of one joule is the energy required to lift a small apple (100 g, or 0.1 kg) against gravity (9.81 m/s2, or approximately 10 m/s2), to a height of 1 meter.

0.1 kg * 10 m/s2 * 1 m ≅ 1 kgm/s2, or 1 J

Although the units for the joule (kgm/s2) are the same as the units for torque (1 kgm/s2 = 1 Nm), a joule is a scalar quantity (it has magnitude only) of force applied through a distance, while torque is a vector quantity (it has both magnitude and direction) of force applied at a distance.

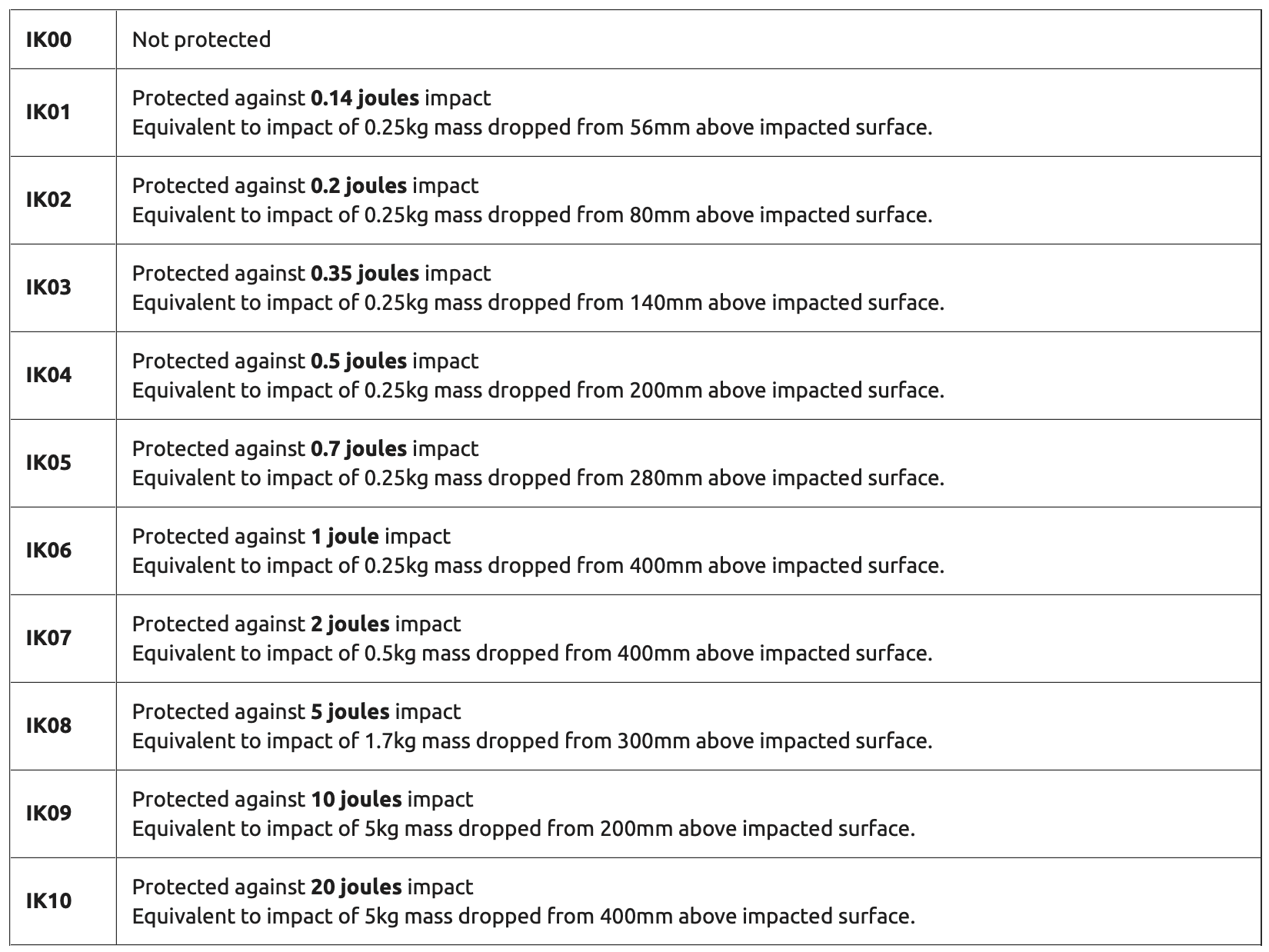

The IK rating was originally introduced as the European standard BS EN 50102 in 1995, but was replaced by the international standard IEC 62262 (and the renumbered European standard EN 62262) in 2002. Prior to these standards, an impact protection rating was often added to the end of an enclosure’s IP rating. For example, IP66(9) would mean the enclosure had an IP rating of 66 and an impact rating of 9. The IEC 62262 standard provides ten levels of protection, designated by two-digit codes, from 00 (no protection) to 10 (highest level of protection).

An enclosure’s IK rating is determined by a testing procedure set out in IEC 62262. The testing procedure involves impacts administered by a pendulum-type device, which uses hammers of various weights to simulate different masses being dropped from increasing distances from the impacted surface. The impact tests, known as “Charpy tests,” are carried out for every surface that is exposed during normal usage of the enclosure. For an enclosure with an area to be tested that is less than 1 meter in length, three impacts are administered. For a tested area over 1 meter in length, five impacts are administered.

Image credit: TWI Ltd.

The IEC 62262 standard specifies that the locations of the impacts should follow a certain symmetry and should be distributed evenly over the surface, but the manufacturer has significant discretion in choosing where the impacts are located. And parts such as hinges and locks are excluded from testing. Therefore, it’s important to understand the manufacturer’s testing procedure, as the enclosure’s IK rating can be affected by where the impacts were applied.

In addition to how and where the impacts are administered, IEC 62262 also specifies how the enclosure should be mounted and the atmospheric conditions that should be present during testing. It also provides instructions for the size, dimensions, style, and materials of the hammers to be used for testing.

Note that an enclosure must meet both the stated ratings, IP and IK, together. For example, if an enclosure maintains its IP66 rating after passing the test for IK06 protection, it can be labeled as both IP66 and IK06. However, if, after the enclosure passes testing for IK08 protection, it only maintains IP54 protection, then it must be labeled as IK08 and IP54, or IK06 and IP66, but it cannot be labeled as IK08 and IP66.

Leave a Reply

You must be logged in to post a comment.