The U.S. Department of Energy (DOE) has been regulating energy efficiency for electric motors since 1997, when the Energy Policy Act went into effect, requiring most 1 to 200 hp general-purpose motors to meet NEMA Energy Efficiency standards. Since then, the DOE energy efficiency regulations have evolved, with the Energy Independence and Security Act (EISA) of 2007 upping the efficiency requirements for 1-200 hp general-purpose motors to the new NEMA Premium Efficiency levels and adding the requirement for certain 201 to 500 hp motors to meet NEMA Energy Efficiency standards.

However, the 2007 EISA standard — which went into effect in December of 2010 — left significant gaps in the motors that were covered and made it relatively easy for manufacturers to work around the rules by producing motors with slight deviations from those covered by the standard — such as special mounting designs not specified in the regulations.

In 2010, a motor coalition was formed in order to, “Determine and document a plan to improve the efficiency of the greatest number of units, providing the greatest savings impact while reducing potential enforcement issues, while maintaining full product utility for American industry.” As a result of this coalition’s work, the Amended Integral HP Rule was released in May of 2014 and was implemented in June of 2016 as the Integral HP Motor Final Rule.

This Integral Horsepower Rule supersedes the EISA standard and specifies that nearly all motors covered must meet NEMA Premium Efficiency levels. But more importantly, it closes the gaps and potential loopholes in the EISA standard and expands the scope of covered motors to those that meet the following criteria:

- Is a single speed induction motor

- Is rated for continuous duty (MG 1) operation or for duty type S1 (IEC)

- Contains a squirrel-cage (MG 1) or cage (IEC) rotor

- Operates on polyphase alternating current (AC) 60-hertz sinusoidal line power

- Has 2-, 4-, 6-, or 8-pole configuration

- Is rated 600 volts or less

- Has a three or four digit NEMA frame size (or IEC metric equivalent), including those designs between two consecutive NEMA frame sizes (or IEC metric equivalent) or an enclosed 56 NEMA frame size (or IEC metric equivalent)

- Has no more than 500 horsepower, but greater than or equal to 1 horsepower (or kilowatt equivalent)

- Meets all the performance requirements of a NEMA design A, B or C electric motor or an IEC design N or H electric motor

Image credit: U.S. Department of Energy

Still, the Integral Horsepower Rule does not include all motors used in industrial applications. The most significant omissions from the rule, relevant to industrial motion and motion control include:

- Synchronous AC motors

- Permanent magnet rotor AC motors

- Servo motors

But there’s a good reason these motors aren’t covered by the Integral Horsepower Rule. The DOE considers permanent magnet (PM) motors, switched reluctance (SR) motors, and synchronous reluctance (SynRM) motors to be “newly emerging” or “advanced” technologies that can achieve significantly higher efficiency levels than NEMA Premium Efficiency. In fact, these motors may meet or exceed “super efficiency” standards, which have been explored, but not finalized or published, by NEMA.

Specifically, NEMA recognizes that permanent magnet and switched-reluctance motors have both high power density (torque-to-weight ratio) and high efficiency and recommends that they be considered for many types of industrial applications, including:

- When the application requires speed control (i.e., when an adjustable speed drive is required for speed regulation)

- When driven equipment is in operation for over 2,000 hours per year

- When an old standard efficiency motor is driving a centrifugal load with throttled or damper flow control and can be replaced with a variable speed PM or SR motor and controller

- When operations involve frequent starts and stops (this is a good application due to the low inertia of PM and SR motors)

- When small motors operate at partial load a good deal of the time

- When the PM or SR motor can be used in a direct drive configuration to displace a single or two-speed motor with gearbox (e.g., a cooling tower fan drive motor), a gear motor, or a belted power transmission system

- In vertical pump-mount applications where resonance frequencies must be avoided.

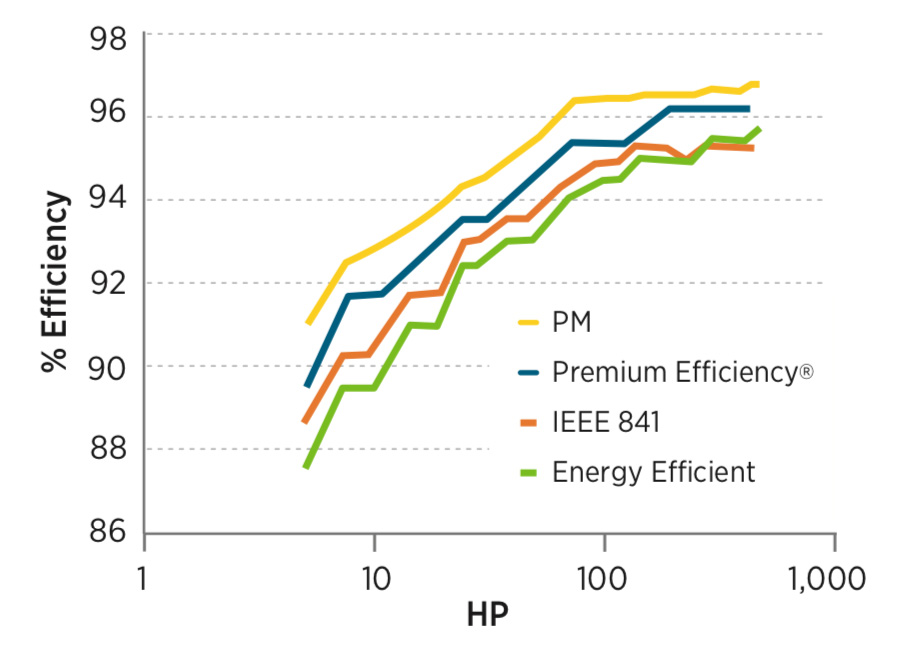

The chart below demonstrates the efficiency of permanent magnet motors as compared to NEMA Energy Efficient and Premium Efficiency motors, as well as to IEEE 841 motors.

Image credit: Baldor Electric

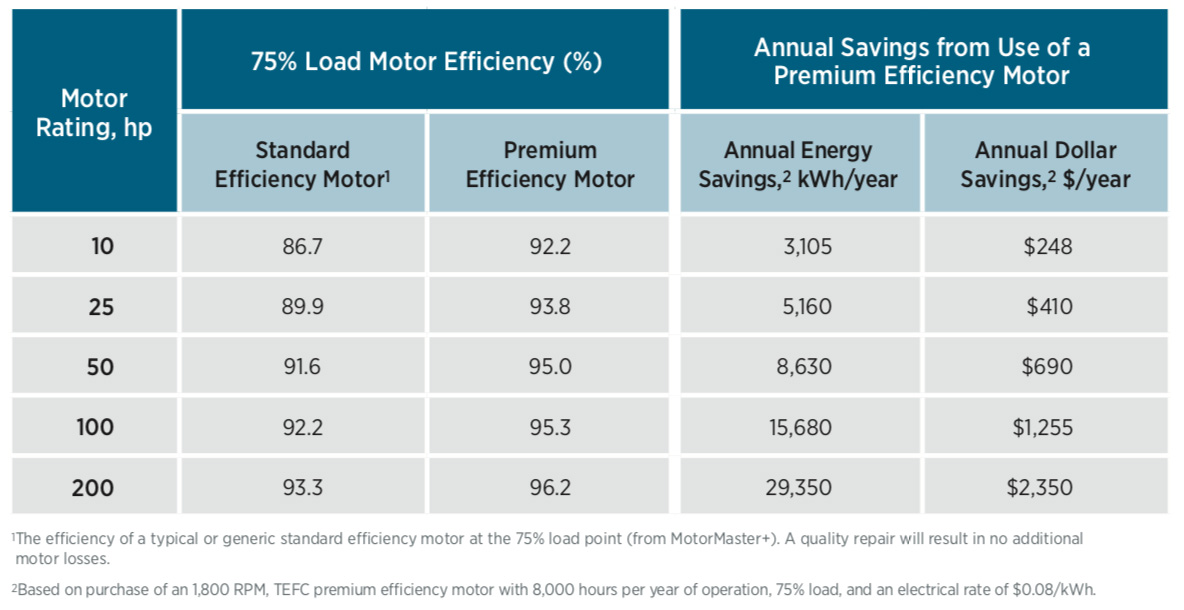

NEMA Premium Efficiency sets forth full-load efficiency standards for 1 to 500 hp, three-phase, low-voltage NEMA Design A and B general, special, and definite purpose induction motors. Because the Premium Efficiency levels are provided in Table 12-12 of the NEMA MG1 Motors and Generators standard, it is sometimes referred to as “12-12 efficiency.” For motors not produced in the United States, the IE3 classification, as defined in the IEC 60034-30-1 standard, is generally compatible with the NEMA Premium Efficiency standard.

Leave a Reply

You must be logged in to post a comment.