Increasing globalization and industrialization are spurring high-capacity manufacturing with even less tolerance for errors than ever before. These applications are leveraging servomotors and drives in their quest to achieve better efficiency with automation. This is because servomotors are one of the most commonly used motors for precision positioning and load-responsive motion.

Servomotors power applications in a wide range of industries, though are most suited for controlling the movement of machines in packaging, textile production, semiconductor manufacturing, as well as medical equipment and food and beverage production. Other common applications include robotics, positioning systems and tracking systems for solar panels. Here and elsewhere, servomotor technology can help boost accuracy and output.

Selecting the right servomotor for an application involves three important parameters: load, speed and torque.

Not only must acceleration, deceleration and running torque be taken into account, but also the ability of the servomotor to tightly control the load’s speed, position or torque. This means the peak torque measurements must be calculated, usually during acceleration or deceleration, along with the running/normal torque. Also, the inertia of the system (the load’s resistance to change in speed) must be calculated to ensure that the motor/drive system will be able to control the load.

A motor’s continuous torque is its ability to produce the rated torque and speed without overheating. Intermittent torque indicates how much torque a motor can produce in a short period of time based on current limits of the drive and motor. The intermittent (or peak) torque of a motor can be much higher than its rated torque, and servo systems are usually designed to operate within that peak torque range when accelerating or decelerating the load.

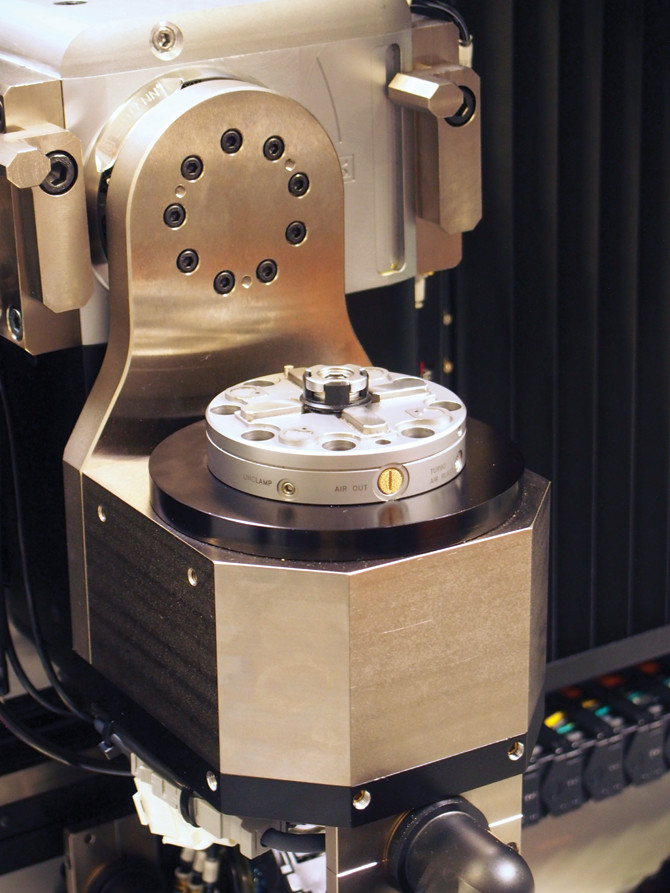

Small size makes big difference for micro-machining innovator

Microlution builds equipment that can create machined components of an exceptionally small size at extremely high levels of precision. Tiny parts are cut, milled, drilled and turned on equipment that achieves a positional accuracy of ±0.00004 in. (1 micron). Precisely controlled high-speed spindles operating at more than 50,000 rpm offer high volume production of intricate micro components for end users in the automotive, medical, aerospace and consumer products industries.

Near-microscopic output isn’t the only size advantage the company offers. Today’s manufacturers are increasingly concerned over the scarcity of space on the production floor. Microlution responds with machines that pack an abundance of high-precision capability into a footprint as small as 2 ft wide, and a height of less than 5 ft.

Company founders Anthony Honegger and Andy Phillip have had to search for components that deliver exceptionally precise and highly consistent movement, with a form factor that fits within a fraction of the space occupied by standard industry products.

Development of rotary tables has been a particular challenge. “The solution we need doesn’t exist from existing CNC rotary table builders,” Honegger said. “Gear-driven solutions are fairly compact, but they don’t offer the performance we need. There is also the issue of backlash with mechanical tables. Direct-drive servo tables have the precision and the speed, but they are far too large. Some of them are as big as our entire machine.”

After a thorough investigation, the Microlution team decided it would be wisest to design and build a rotary table on their own. Success demanded a direct-drive servomotor that would fit in the available space in a Microlution machine, yet provide the torque required to rotate parts for a high-throughput machining process. An extensive search uncovered the Yaskawa SGMCV-04, a direct-drive servo with a height of only 53 mm (2 in.) and a diameter of 135 mm (5.3 in.). Even though the size is a fraction of the footprint required for comparable direct-drive servos, the SGMCV-04 has a torque output of 4 Nm and a power output of 126 W. This level of performance proved to be enough for Microlution’s fine cutting applications.

The direct-drive motor’s rotor couples directly to the chuck, eliminating gears and other mechanical transmissions and yielding a big improvement in accuracy and responsiveness. Eliminating mechanical compliance enables accurate and immediate response to position, velocity and acceleration demands. “An improvement of fractions of a second could give you a 10% increase in tact time,” Honegger said. “At these rates, the benefits of direct-drive technology become obvious pretty quickly.” He also noted that a direct-drive rotor table removes the mechanical backlash that leads to poor positioning of the part being machined. “When you’re machining parts that are smaller than a fingernail, even a small lack of compliance can be a big issue,” he added.

The table’s mechanism needed to be well protected from chips, dust and cutting fluids to function reliably. The engineers at Microlutions chose to encase the Yaskawa servo in a sealed enclosure, with a liquid-cooled bottom plate to maintain the proper operating temperature. “In our applications, temperature control is critical,” said Honegger. “With precision like this, a degree of temperature variation here or there could ruin our accuracy.”

The native precision of the Yaskawa direct-drive servo was further reinforced by augmenting the servo’s existing bearing with a cross roller bearing at the top of the enclosure, adding rigidity and minimizing the possibility of off-axis motion during the indexing process. The Microlution engineering team also chose to implement linear servos to control some of the machine’s other axes. By moving from mechanical transmission components like ballscrews, belt drives and mechanical gearing toward a completely servo-controlled mechanism, a Microlution machine eliminates the mechanical compliance issues that diminish system speed and accuracy.

As a bonus, the Yaskawa direct drive meets Microlution’s need to comply with the safety standards of customers worldwide. The Safe Limited Speed function built into the Yaskawa servo’s amplifier helps the machines meet CE safety standards for delivery into the EU. “Having both the STO to turn the unit off and the safety limited speed was a big advantage for us,” Honegger said. “Having that capability built into the amp meant we didn’t need to develop a solution on our own. We were CE compliant right out of the box, which saved us a lot of time.”

The new rotary table design is now a standard part of Microlution’s high-volume machines. It also holds the potential to be a successful retrofit for existing Microlution products now in place. “The time savings is significant. Customers can probably gain a big improvement in speed and a 10% improvement in throughput,” said Honegger. “At another company where we have four machines, we’ve estimated that a retrofit could increase throughput by 20%.”

Thanks to Jeff Watter of Yaskawa America for this application story.

Leave a Reply

You must be logged in to post a comment.