Modern motion systems demand ultra-fast deterministic communication with precise multi-axis synchronization. So, engineers are turning to realtime Ethernet-based industrial protocols. Neyram Hemati, PhD Ankit Barad | Applied Motion Products Realtime motion control depends on fast, deterministic communication and precise synchronization across multiple axes. Among Ethernet-based technologies: EtherCAT delivers the highest synchronization accuracy and speed. EtherNet/IP […]

Trends in software ecosystems for motion

Some of the latest developments in software ecosystems aim to make motion systems easier to design and commission. Artificial intelligence (AI) has made rapid inroads here. For motion systems specifically, the trend is to use AI for: Servotuning — before a system is put into service. Predictive maintenance — when a system is running in […]

Robotics design leverages motion development

Helping robotics companies bring their projects to completion, OLogic increasingly turns to Performance Motion Devices for motion control technology without limits. Silicon Valley–based OLogic has helped robotics and consumer electronics companies — from startups to industry leaders — bring products to market. Past customers include NVIDIA, Google, Hasbro, Panasonic, Toyota Research Institute, and Carnegie Mellon […]

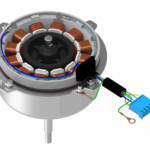

What’s really the difference between a dc servo and an ac servo system?

This article provides a history and general guidance on the capabilities of different ac and dc servo technologies. By Hurley Gill • Senior applications and systems engineer | Kollmorgen Many of today’s industrial and commercial applications — whether controlling a specific operation or just some specific motion — require electric motors. These ac and dc […]

Vert-X 26-series angle sensors are robust and accurate

Novotechnik U.S. now offers Vert-X 26-series of non-contacting magnetic angle sensors. These sensors use a Hall effect to track the position of the shaft. Designed for challenging settings where high humidity, dampness, dust and vibrations are expected, these are suitable for automotive, off-highway, and other applications. The plug-in sensors using an AMP MQ5 six-pole connector. […]

Announcing the 2025 LEAP Awards in industrial automation

Now in its eighth year, Design World’s annual Awards in Leadership in Engineering Achievement Program highlights innovation and engineering achievements from around the globe. This year, the expert independent judging panel reviewed dozens of submissions to award gold, silver, and bronze winners across multiple categories. The following products were recognized in the 2025 LEAP Awards […]

A simple PID loop tuning technique: Part 2 of 2

Proportional, integral, derivative (PID) position servo-loop tuning can be daunting. However, one simple technique works well for most systems. Chuck Lewin • Founder and CEO | Performance Motion Devices Inc. The first installment of this two-part series detailed a simple technique called step-response tuning that helps identify good PID-gain settings in motor-positioning applications. This manual […]

A simple PID loop tuning technique: Part 1 of 2

Proportional, integral, derivative (PID) position servo-loop tuning can be daunting. However, one simple technique works well for most systems. Chuck Lewin • Founder and CEO | Performance Motion Devices Inc. There are two types of servomotors commonly used for positioning motion control applications — the dc brush motor (which uses mechanical brushes to commutate the […]

New motor could spur new applications

It often happens than new technologies enable new forms of automation — or makes them more practical. One new electric-motor design recognized by this year’s R&D 100 Awards could prove one such technology. Lisa Eitel | Executive editor Most electric vehicle or EV motors use permanent-magnet synchronous motors or PMSMs with the magnets on their rotors, and […]

Motion control boosts fence-post drilling throughput

On the manufacturing floor of British Columbia-based BKB Cedar Manufacturing, the whine of the drill motor and churning of its bit into tough cedar posts made a reassuringly steady cadence — until, too often, it didn’t. Workers would manually position posts by moving a heavy carriage back and forth between drilling operations. They would then […]